In the business for many years,

we have high-quality raw material supply channels,

providing more than 50 types of thermoplastics and thermosetting plastics for injection molding for manufacturing,

suitable for many industries such as medical care, new energy, consumer electronics, and daily necessities.

Customers can choose models with confidence and focus on product manufacturing.

Rigid Materials

ABS

ABS material is currently the largest and most widely used polymer, with excellent impact resistance, heat resistance, low temperature resistance, chemical resistance and electrical properties.

It also has the characteristics of easy processing, stable product size, and good surface gloss. It is easy to paint and color, and can also be used for secondary processing such as surface metal spraying, electroplating, welding, hot pressing, and bonding.

Widely used in industrial fields such as machinery, automobiles, electronic appliances, instrumentation, textiles and construction.

| Tensile Strength(Mpa): | 35~62 | moisture absorption(%): | 0.2~0.45 |

| Shrinkage(%): | 0.3~0.8 | CLTE(×10-5 /K)/℃: | 8 |

| Density(g/cm3): | 1.05 |

ABS+PC

ABS engineering plastic is PC+ABS (engineering plastic alloy). It has impact resistance and excellent processing fluidity of ABS resin.

Therefore, when applied to thin-walled and complex-shaped products, it can maintain its excellent performance and maintain the formability of plastics and a material composed of an ester.

The largest application areas of ABS resin are automobiles, electronic appliances and building materials.

| Tensile Strength(Mpa): | 40 | moisture absorption(%): | 0.2~0.45 |

| Shrinkage(%): | 0.4~0.6 | CLTE(×10-5 /K)/℃: | 8 |

| Density(g/cm3): | 1.15 |

LCP

LCP (Liquid Crystal Polymer) material is a high-performance engineering plastic with excellent thermal stability, mechanical strength, solvent resistance, flame retardancy and electrical properties. It is a thermoplastic with fully crystalline molecular chain, also known as liquid crystal polymer material.

It is commonly used in the manufacture of components that require high precision and high performance, such as automotive parts, electrical and electronic components, medical devices, industrial equipment, and aerospace equipment.

Due to its special molecular structure, LCP material has a very low coefficient of thermal expansion and excellent resistance to deformation, making it an excellent material for heat exchangers.

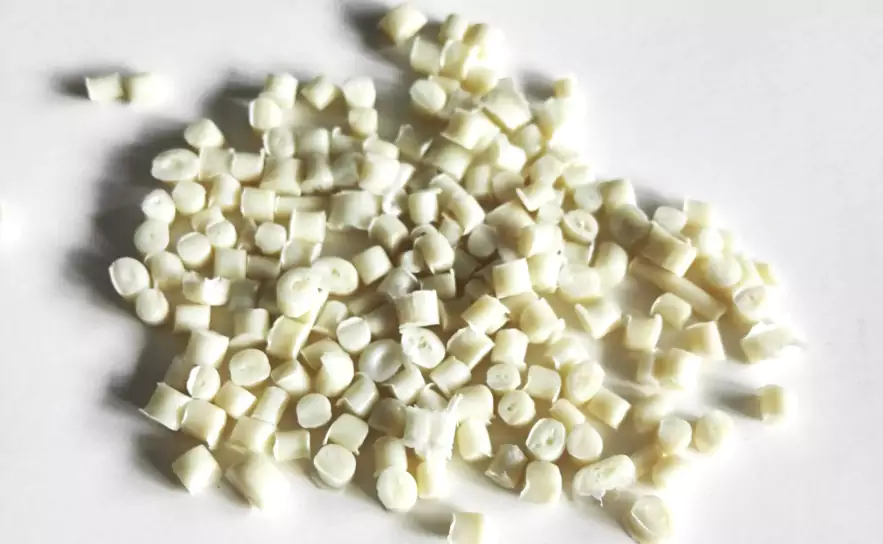

Nylon 6

Polyamide 6 or Nylon 6 (PA6) Properties: translucent or opaque milky white crystalline polymer.

Features: thermoplastic, light weight, good toughness, chemical resistance and durability; good wear resistance, self-lubricating and solvent resistance

Combustion identification method: yellow flame on blue background.

Advantages of the material:

- High mechanical strength, good toughness, high compressive and tensile strength (tensile strength is more than twice that of ABS)

- Excellent wear resistance and small friction coefficient

- High fatigue resistance, repeated bending mechanical strength is not affected

- Corrosion resistance, mainly for alkaline and most saline liquids, inert to biological erosion, antibacterial and anti-mildew.

- High heat resistance, excellent electrical performance.

Nylon 66

Nylon-66 is a thermoplastic resin, which is generally produced by polycondensation of adipic acid and hexamethylenediamine. Insoluble in common solvents, only soluble in m-cresol, etc.

Features:

- High mechanical strength.

- Good resistance to stress cracking, it is the PA with the best wear resistance, and excellent self-lubricating property, second only to polytetrafluoroethylene and polyoxymethylene.

- It has good heat resistance and is a self-extinguishing material.

- Good chemical stability, especially excellent oil resistance, but easily soluble in polar solvents such as phenol and formic acid.

- Adding carbon black can improve the weather resistance; the water absorption is high, so the dimensional stability is poor.

- Good molding processability, can be used for injection molding, extrusion, blow molding, spraying, casting molding, machining, welding, bonding.

Nylon 11

White translucent thermoplastic resin. The relative density is 1.04~1.05(g/cm3), the melting point is 187 degrees Celsius, the tensile strength is 50 to 59 MPa impact strength, the heat distortion temperature is 54 degrees Celsius, and it is self-extinguishing.

It has the permeability of nylon resin, and is characterized by low relative density, low water absorption, softness and excellent low temperature resistance. It is formed by polycondensation of d-amino acid in an autoclave.

Suitable for injection molding, extrusion molding, vacuum forming, rotational molding and centrifugal casting, etc. It can be plasticized and reinforced for filling modification. It is especially suitable for making various hoses, packaging films, cable sheaths, wear-resistant parts, military and aerospace materials.

The powder can be used for roll dipping and electrostatic spraying to impart abrasion and chemical resistance to metal surfaces. Resistant to common acids, alkalis and oxidants.

Nylon 12

Nylon 12, relative density 1.01~1.02(g/cm3), melting point 178 degrees Celsius, tensile strength 50~64MPa, bending strength 74MPA cantilever beam (notch) impact strength 4~6kJ/m, heat distortion temperature (1.82MPa) 54.5 degrees Celsius.

Excellent wear resistance, self-lubrication, flexibility, low moisture absorption, and strong adhesion to metals.

It can be formed by extrusion molding, injection molding dipping, electrostatic coating, flame spraying, rotational molding and other methods.

It can be enhanced, filled and modified. It is mainly used for oil-resistant hoses, monofilaments, metal adhesives, heat-sensitive wires, precision mechanical parts, wear-resistant parts of electrical instrument parts, and can also be used to make aerospace military parts.

PBT

It has high heat resistance, toughness, fatigue resistance, self-lubricating, low friction coefficient, weather resistance, low water absorption, only 0.1%, and still maintains various physical properties (including electrical properties) and electrical insulation in a humid environment. However, volume resistance and electrical loss are large.

Resistant to hot water, alkalis, acids, oils, but easily corroded by halogenated hydrocarbons, poor hydrolysis resistance, rapid crystallization at low temperature, good formability. The disadvantage is that the notched impact strength is low and the molding shrinkage is large.

Therefore, most of them are reinforced by glass fiber or modified by inorganic filling, the tensile strength and bending strength can be more than doubled, and the heat distortion temperature is also greatly increased.

PC

PC is an almost colorless glassy amorphous polymer with good optical properties. PC high molecular weight resin has high toughness, the notched impact strength of the suspension beam is 600~900J/m, and the heat distortion temperature is about 130 degrees Celsius. After glass fiber reinforcement, this value can be increased by 10 degrees Celsius.

The flexural modulus of PC can reach more than 2400MPa, and it can be processed into large rigid products. Below 100°C, the creep rate under load is very low. PC has poor hydrolysis resistance and cannot be used for products that are repeatedly subjected to high-pressure steam.

The main performance defect is that the hydrolysis resistance stability is not high enough, it is sensitive to notches, the scratch resistance is poor, and it will turn yellow when exposed to ultraviolet light for a long time. Like other resins, PC is susceptible to clouding by certain organic solvents. PC material has flame retardancy, wear resistance and oxidation resistance.

PE

PE is a polymer with various structures and properties. It has excellent low temperature resistance (the lowest operating temperature can reach -100~-70°C), good chemical stability, and can resist most acids and alkalis (not resistant to acids with oxidizing properties). Insoluble in common solvents at room temperature, low water absorption, excellent electrical insulation.

It is very sensitive to environmental stress (chemical and mechanical action), and its heat aging resistance is poorer than that of the polymer’s chemical structure and processing. Polyethylene can be processed by general thermoplastic molding methods.

It has a wide range of uses, mainly used to manufacture films, packaging materials, containers, pipes, monofilaments, wires and cables, daily necessities, etc., and can be used as high-frequency insulation materials for TVs and radars.

PEI

PEI is a strong and transparent material that can handle high temperatures. It’s good at resisting damage and can work well in electronics, machines, and airplanes. People use it instead of metal to make things like connectors for fiber optics, which helps make them smaller and more precise.

In cars, PEI can be used to make parts like connectors, lights, and sensors that control temperature. It’s also useful for making things like vacuum pump parts, and even special glass joints and lamp reflectors.

Overall, PEI is a versatile material that’s used in many different ways to improve products in various industries.

LDPE

Low density polyethylene, heat-welding property, good forming process performance, good flexibility, good impact toughness, low-temperature resistance, can work at -60C~-80C, density is 0.910~0.9259/cm3.

The mechanical strength is poor, the heat resistance is not high, the environmental stress cracking resistance, adhesion, adhesion, and printing are poor, and surface treatment is required.

LDPE is also used in injection molding products, such as small containers, lids, daily products, plastic flowers, injection-stretch-plastic containers.

Medical equipment, pharmaceutical and food packaging materials, extruded pipes, plates, wire and cable coating, profiles, thermoforming and other products;

Blow molding hollow molding products, such as food containers for dairy products and jams, medicines, cosmetics, chemical product containers, tanks, etc.

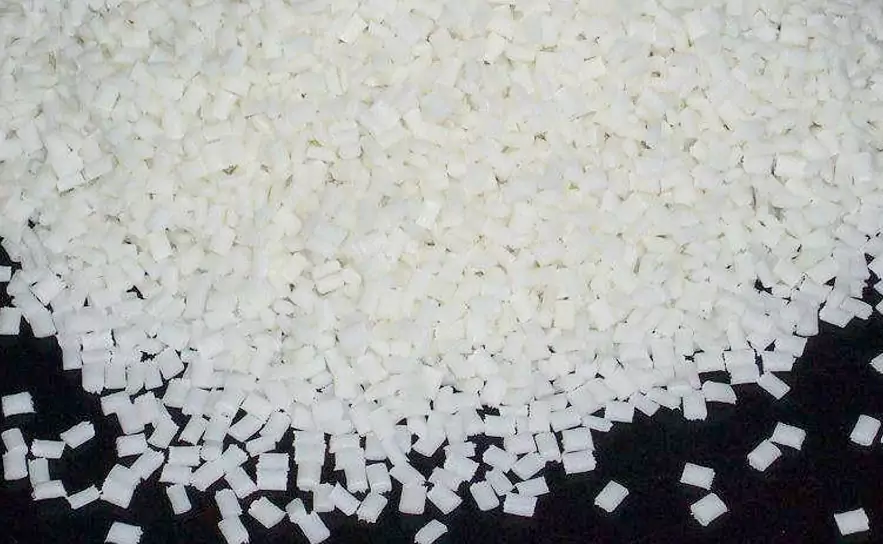

HDPE

HDPE is a highly crystalline, non-polar thermoplastic resin. High-density polyethylene is a white powder granular product, non-toxic, and the density is in the range of 0.940~0.976g/cm3;

Advantages: acid and alkali resistance, organic solvent resistance, excellent electrical insulation, and can still maintain a certain degree of toughness at low temperatures. Surface hardness, tensile strength, rigidity and other mechanical strengths are higher than LDPE, close to PP, and tougher than PP, but The surface finish is not as good as PP.

Disadvantages: poor mechanical properties, poor air permeability, easy deformation, easy aging, easy to become brittle, brittleness is lower than PP, easy to stress cracking, low surface hardness, easy to scratch. Difficult to print, when printing, surface discharge treatment is required, electroplating is not possible, and the surface is matte.

Application: used for extruding packaging films, ropes, woven bags, fishing nets, water pipes; injection molding of low-grade daily necessities and shells, non-load-bearing components, plastic boxes, turnover boxes; extrusion blow molding containers, hollow products, bottles.

PET

PETPET is a polyol resin, collectively referred to as thermoplastic polyol together with PBT. Milky white or light yellow, highly crystalline polymer with a smooth and shiny surface.

It has good mechanical properties, the impact strength is 3~5 times that of other films, and it has good folding resistance.

Resistant to oils, fats, dilute acids, dilute alkalis, and most solvents.

With excellent high and low-temperature resistance, it can be used in the temperature range of 120C for a long time, short-term use can withstand high temperature of 150C, and can withstand low temperatures of -70C, and the high and low temperatures have little effect on its mechanical properties.

Gas and water vapor permeability is low, and it has excellent gas barrier, water, oil and odor performance.

It is non-toxic, tasteless, hygienic and safe, and can be directly used in food packaging.

PP

PP is a non-polar crystalline plastic with a very low water absorption rate of about 0.03%~0.04%, and generally does not need to be dried during injection molding. Its specific gravity per cubic centimeter is about 0.9-0.91 grams, and the shrinkage rate is between 1.0-2.5%.

In addition, it also has the characteristics of colorless, odorless, non-toxic, light weight, good toughness, and good chemical resistance. The disadvantages are low dimensional accuracy and poor weather resistance. After demoulding, it is prone to problems such as aging, brittleness, and deformation. .

It is mainly used to manufacture various mechanical equipment parts, such as manufacturing industrial pipes, agricultural water pipes, motor fans, infrastructure templates, etc., as well as insulating shells of household appliances and inner tanks of washing machines, as well as insulating materials for wires and cables and other electrical appliances.

PPA

The heat distortion temperature of PPA plastic is as high as 300°C, and the continuous use temperature can reach 170°C, which can meet your short-term and long-term thermal performance.

PPA has superior strength, toughness and hardness, as well as its good heat resistance, chemical resistance and crack resistance.

Because it can still maintain strength and hardness under high temperature and high humidity environment, it can replace metal where traditional nylon and polyester cannot be used.

It also has superior surface gloss. It can be tinted without surface painting, helping to reduce the visibility of surface nicks and scratches.

PPS

PPS is a white powder, specific gravity: 1.36 g/cm3, molding shrinkage: 0.7%. It is a thermoplastic special engineering plastic with excellent comprehensive properties, and its outstanding features are high temperature resistance, corrosion resistance and superior mechanical properties.

Mainly used in automotive functional parts, igniters, heater thermostats, lamp holders, bearings; for example, it can replace metal to make exhaust simple circulation valves and water pump impellers, pneumatic signal conditioners, etc.

It can also be used for shells, structural parts, wear-resistant parts and sealing materials, specifically pump bodies, valves, bearings, bearing brackets, piston rings and gears.

PMMA

PMMA is a highly transparent amorphous thermoplastic polymer with a relative density (30℃/4℃) of 1.188~122. High transparency, light transmittance 90%~92%, higher than plexiglass, and can pass through ultraviolet light up to 73.5%. The refractive index is 1.49. High mechanical strength, good toughness, tensile strength 60~75MPa, impact strength 12~13kJ/m, 8~10 times higher than inorganic glass.

Acrylic sheets are widely used in aviation, automobile, electronics, medical, chemical, building materials, sanitary ware and advertising signs and other industries, and are used to manufacture various products: acrylic products, plexiglass display stands, badges, gift boxes , Display stands, signs, signage stands, acrylic key chains, jewelry boxes, jewelry boxes, colorful cases, transparent cases.

POM

POM is a milky opaque crystalline linear thermoplastic resin with good comprehensive performance and colorability, high elastic modulus, high rigidity and hardness, and its strength and rigidity are close to metal;

The disadvantage is that the flame retardancy is poor, it burns slowly in case of fire, and the oxygen index is small. Even if a flame retardant is added, it cannot meet the satisfactory requirements. In addition, the weather resistance is not ideal, and a stabilizer must be added for outdoor applications.

It is widely used in the manufacture of various moving and rotating mechanical parts, as various gears, levers, pulleys, sprockets, especially suitable for bearings, hot water valves, precision metering valves, chain rings and rollers of conveyors, flow meters, automobiles, etc. Internal and external handles, cranks and other window rotating machinery, oil pump bearing housings and impeller gas switch valves, electronic switch parts, fastening bodies, terminal mirror masks, electric fan parts, heating plates, instrument buttons, etc.

PEEK

PEEK is a semi-crystalline, high-performance thermoplastic engineering plastic. PEEK has strong mechanical properties, chemical corrosion resistance, wear resistance, fatigue resistance and dimensional stability, and can withstand high temperatures up to 260 °C.

Disadvantages: expensive; need to process at high temperature; susceptible to corrosion by some acids; low UV resistance.

Main application fields:

Aerospace: aircraft engine parts, turbine blades, gas turbine housings, etc.

Automobile: Automobile engine parts, transmission housings, brake system parts, etc.

Industry: heating elements for heating equipment, heat exchangers, pipes, etc.

Medical devices: artificial joints, dental implants, cardiac pacemakers, etc.

Electronic products: electronic connectors, cable bushings, battery separators, etc.

HIPS

HIPS is a high-performance polystyrene plastic, also known as high-impact polystyrene. It is a thermoplastic with excellent physical properties, including high strength, high toughness, high wear resistance, high chemical resistance and good processability, etc.

It has excellent thermal and shear stability and can accept high levels of regrind without degrading product performance, up to 60% regrind in thermoforming processes.

The largest single-use use of HIPS is as packaging and disposables materials, especially food packaging materials and eating tableware. Key applications include commodity packaging containers. Cups for vending machines and dispensing, various lids, trays. bowls and more. Disposable items such as dishes, bottle caps, safety razors, pen holders, etc. are also part of the high consumption of HIPS.

PSU

PSU plastic is a high-performance engineering plastic, its tensile strength and flexural strength are superior to general engineering plastics such as POM, PA, and PC, and its tensile strength can still reach 60MPa even at 150°C.

Features: High strength, rigidity and non-toxic, ideal for many high-strength and high-stiffness applications.

In the field of electronics and electricity, PSU can be used to make various contactors, connectors, transformer insulation parts, thyristor caps, insulating sleeves, coil skeletons, printed circuit boards, etc.;

In the automotive and aviation fields, PSU can be used to make protective cover components, electric gears, battery covers, detonators, electronic ignition device components, lamp parts, aircraft internal accessories and aircraft external parts, spacecraft external protective covers, etc.;

In the field of medicine and food, it can replace stainless steel products, and can manufacture surgical tool trays, sprayers, fluid controllers, heart valves, pacemakers, gas masks, dental trays, etc.

PU

PU is plastic and alias polyurethane is a polymer compound. There are two types of polyurethanes: polyester and polyether.

Good physical properties, bending resistance, good softness, high tensile strength, and air-attracting properties. The pattern of the PU fabric is to use a kind of pattern paper to paste it on the surface of the semi-finished leather first, and then separate the paper leather for surface treatment after cooling down.

It can be made into polyurethane plastic, polyurethane fiber, polyurethane rubber and elastomer. Widely used in home furnishing, construction, daily necessities, transportation, home appliances, etc.

Elastic Materials

EPDM

EPDM is a terpolymer of ethylene, propylene and non-conjugated diene, the main characteristic is its superior resistance to oxidation, ozone and erosion.

Among all rubbers, EPDM has the lowest specific gravity. It can absorb large quantities of fillers and oils with little effect on properties. Inexpensive rubber compounds can thus be produced.

It has a wide range of uses, and can be used as tire sides, rubber strips, inner tubes, and automotive parts, as well as wires, cable sheaths, and high-voltage and ultra-high-voltage insulation materials. It can also manufacture light-colored products such as leather shoes and sanitary products.

PEBA

PEBA is a high-performance synthetic material, its full name is Polyether Block Amide Elastomer (Polyether Block Amide Elastomer). It is a thermoplastic elastomer with excellent properties such as elasticity, wear resistance and corrosion resistance, as well as good processability and formability.

PEBA materials are widely used in medical equipment, sports equipment, automobiles, electronic products and other fields. For example, catheters, balloons, prostheses, cardiac pacemakers and other components in medical equipment are often made of PEBA materials;

PEBA materials are also commonly used in running shoes, basketball, tennis and other components in sports equipment;

Seals, pipes, hoses and other components in automobile manufacturing can also be made of PEBA materials.

TPE

TPE, the full name of thermoplastic elastomer, refers to a class of recyclable polymer elastic materials, with unique plasticity, stretchability, flexibility and softness, and can also be dyed and processed according to different needs.

Detailed characteristics of TPE material: thermoplastic, good elasticity, wear resistance, environmental protection and safety, good temperature resistance, strong chemical corrosion resistance, adjustable softness and hardness.

The main application is the production of soft rubber toys, luggage accessories, buffers, shock absorbers, tire buffers, handles, steering wheels, dust covers, earphone cables, USB cables, cables, building sealing strips, door and window rubber strips, anti-collision buffer strips, etc. .

TPU

The tensile strength of TPU is 2-3 times that of natural rubber and synthetic rubber. It has excellent wear resistance, and its Taber wear value is 0.5-0.35 mg, which is the smallest among plastics.

The hardness of TPU is Shore A10~Shore D80, while the hardness range of general rubber is usually Shore A60~100.

With biocompatibility and anticoagulant properties, medical TPU is more and more widely used in artificial heart, artificial kidney, blood transfusion, plasma bag, ureter, surgical technology fixation material, etc.

Mainly suitable for wristbands, mobile phone cases, audio, mouse digital equipment, electronic instruments, etc.

TPV

TPV is thermoplastic dynamic vulcanized rubber, which has the resilience of rubber and the processability of plastic, and can be used instead of rubber, so TPV materials are also commonly known as EPDM/PP materials.

TPV is mainly used in various sealing strips/seal materials of automobiles, high-voltage ignition wires, dust covers, air intake pipes, ventilation pipes, buffers, steering wheel foreskins, fenders, etc.

In the construction industry, it is mainly used in the sealing of doors, windows and curtain walls of buildings.

In the electronics industry, it is used to manufacture battery shells, wireless telephone shells and transformer shell sheaths, earphone cable sheaths, earphone cable connectors, power sockets, plugs, sheaths, etc.

LSR

Liquid Silicone Rubber (LSR) is a non-toxic, heat-resistant, high-resilience soft thermosetting material. Its rheological behavior is mainly characterized by low viscosity, fast curing, shear thinning and Higher thermal expansion coefficient values.

LSR’s injection products have good thermal stability, cold resistance and superior electrical insulation, and will not produce toxic substances when burned.

LSR has a wide range of applications, mainly used in health products, automobiles, baby products, medical appliances, diving supplies, kitchen utensils, and sealing applications. LSR is an irreplaceable material in the current production design.

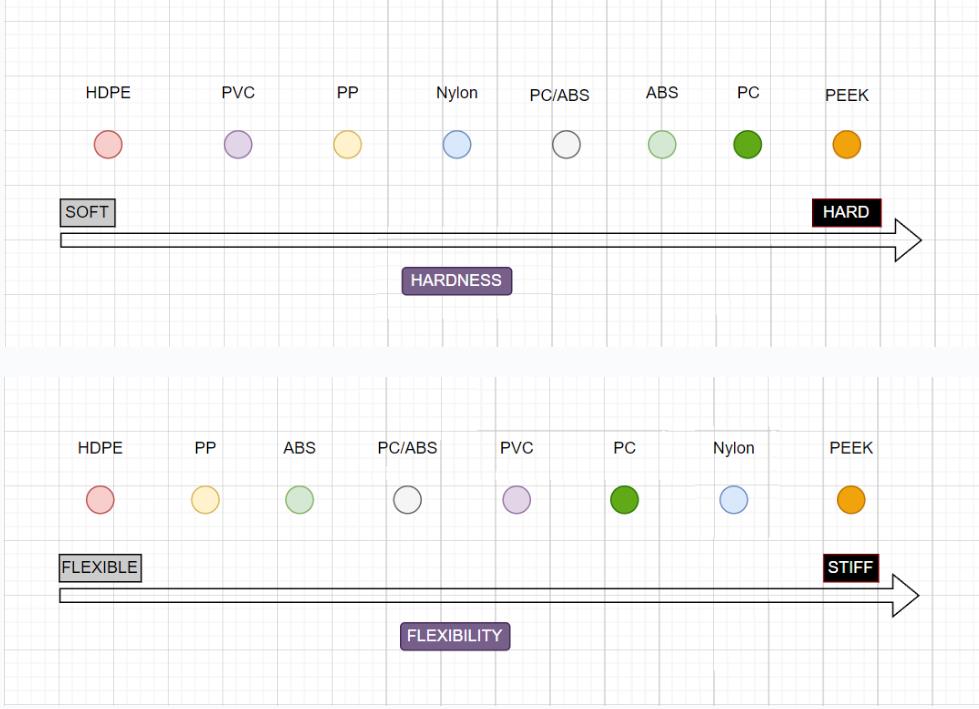

How to Make the Right Choice

When choosing injection molding materials for plastic products, consider key properties: tensile strength, toughness, electrical insulation, temperature resistance, chemical resistance, FDA compliance, and cost.

Tensile strength, measured in PSI, gauges resistance to pulling apart. Izod impact measures toughness by breaking samples, noted in ft·lb/in2.

Flexural modulus, or bending stiffness (psi), shows material flexibility. Dielectric strength (volts/mil) measures electrical insulation.

Chemical resistance safeguards against degradation by chemicals. FDA compliance matters for human-contact products.

Consider thermal properties for heat reactions in thermoplastics. Injection molding parameters can affect shrinkage and stability.

Lastly, factor in cost, which can vary due to availability, material properties, and additives. Cost may be decisive when multiple materials meet requirements.

Plastic |

Tensile Strength Mpa |

Shrinkage % |

moisture absorption % |

CLTE(×10-5 /K)/℃ |

Density g/cm3 |

cost |

|---|---|---|---|---|---|---|

| ABS | 35-62 | 0.3~0.8 | 0.2-0.45 | 8 | 1.05 | $$ |

| HDPE | 27 | 2 ~ 5 | <0.01 | 12.5 | 0.95 | $$ |

| LDPE | 7.0-15.0 | 1.5~5.0 | <0.01 | 22 | 0.92 | $$ |

| HPVC | 45.7 | 0.6~1.0 | 0.07-0.4 | 5 | 1.5 | $$ |

| SPVC | 10.5-20.5 | 1.5~2.5 | 0.25 | 1 | 1.4 | $$ |

| PA6 | 74 | 0.6~1.4 | 3 | 8.3 | 1.14 | $$ |

| PA6+30%GF | 110 | 0.3~0.7 | 1.1 | 2.2 | 1.37 | $$ |

| PA66 | 80 | 0.8~1.5 | 3.4~3.6 | 7 | 1.15 | $$ |

| PA66+30%GF | 189 | 0.2~0.8 | 0.5~1.3 | 1.38 | $$ | |

| PBT | 55 | 0.44 | 0.09 | 9.2 | 1.31 | $$ |

| PBT+30%GF | 137 | 0.2 | 0.07 | 2.7 | 1.53 | $$ |

| PET | 78 | 1.8 | 0.26 | 10 | 1.38 | $$ |

| PI | 100 | 0.75 | 0.3 | 3 | 1.38 | $$ |

| PMMA | 55~77 | 0.2~0.8 | 0.34 | 7 | 1.19 | $$ |

| POM | 62 | 1.5~3.5 | 0.21 | 8.5 | 1.41 | $$ |

| POM+25%GF | 130 | 2.6 | 1.61 | $$ | ||

| PC | 61 | 0.5 | 0.15 | 7.2 | 1.2 | $$ |

| PC+30%GF | 132 | 0.2 | 0.1 | 2.7 | 1.45 | $$ |

| PP | 29 | 1~2.5 | 0.01 | 8 | 0.9 | $$ |

| PS | 50 | 0.4~0.7 | 0.05 | 8 | 1.05 | $$ |

| PEEK | 103 | 10 | 1.3 | $$$$$$ | ||

| PEKK | 102 | 1.3 | $$$$$$ |

Material |

Flexibility |

Impact Strength |

Electrical Insulation |

Temperature Resistance |

Chemical Resistance |

FDA Compliant |

Cost (low to high) |

Water Resistant |

|---|---|---|---|---|---|---|---|---|

| Acrylic (PMMA) | low | low | no | high | strong | no | medium | yes |

| Acrylonitrile Butadiene Styrene (ABS) | high | high | no | low | medium | no | medium | yes |

| Nylon Polyamide (PA) | high | high | yes | high | strong | yes | high | yes |

| Polycarbonate (PC) | high | high | no | high | weak | yes (can contain bisphenol A, or BPA) | high | yes |

| Polyethylene (PE) | medium (LDPE) low (HDPE) high (PET) |

high (LDPE) high (HDPE) low (PET) |

yes | low | strong (LDPE) strong (HDPE) strong (PET) |

yes | low | yes |

| Polyoxymethylene (POM) | medium | high | yes | high | strong | yes | high | |

| Polypropylene (PP) | high | medium | yes | medium | strong | yes | low | yes |

| Polystyrene (PS) | medium | high | no | medium | yes | low | yes | |

| Thermoplastic Elastomer (TPE) | high | high | no | low | strong | no | high | yes |

| Thermoplastic Polyurethane (TPU) | high | no | high | strong | yes | medium | yes | |

| PC/ABS | low | high | no | medium | strong | yes | low | yes |

| PC/PBT | low | high | yes | high | medium | yes | medium | yes |

| PPE/PS | low | medium | no | high | medium | yes | medium | yes |

Resin Type |

Benefits |

Applications |

Considerations |

|---|---|---|---|

POM or Acetal (Polyoxymethylene) |

Tough, stiff, hard, and strong. Good lubricity and resistance to hydrocarbons and organic solvents. Good elasticity, slippery. Low creep. Great fatigue properties. |

Gears, pumps and pump impellers, conveyor links, soap dispensers, fan and blower blades, automotive switches, electrical switch components, buttons, and knobs. |

Due to shrink, you need uniform wall thickness. Painting, coating, and achieving high-cosmetic finish difficult. |

PMMA or Acrylic (Polymethyl Methacrylate) |

Good optical properties, high gloss, scratch resistant. Low shrink, Less sink in geometries with thin and thick sections. |

Light pipes, lenses, light shades, optical fibers, signs. |

Can be brittle. PC is a good alternative. Draft always required, sometimes twice as much as other materials. Poor chemical resistance. |

ABS (Acrylonitrile butadiene styrene) |

Tough, impact- and chemical-resistant, low shrink, high dimensional stability, inexpensive |

Cosmetic parts, handheld devices, housings, and moldings for electrical tools, remote controls, computers, telephone components |

Show knit lines and can have sink and voids in thick areas. You might be able to reduce sink by switching to an ABS/PC-blend. |

HDPE (High-density polyethylene) |

Tough, impact- and chemical-resistant, high shrink, low dimensional stability, inexpensive, density less than water (floats) |

Lawn furniture, totes, containers, toys, gas cans |

High shrink, low surface energy |

PC (Polycarbonate) |

Strong, extremely impact resistant, low shrink, good dimensional stability and heat resistance, accepts high cosmetic finishes well |

Lenses, indoor and outdoor lighting, cell phone housings, electrical components, medical devices, bulletproof glass. |

Possible sensitivities in thick sections of parts could cause voids, bubbles, and sink. Poor chemical resistance. An ABS/PC blend is a good alternative for opaque parts with these issues Acrylic is another option for parts with thick geometries. |

ABS/PC |

Strength, heat and low-temperature resistance, improved processing, |

Automotive, electronic, telecommunications |

Improved thick molding and mechanical properties compared to just ABS or PC. Lower cost than PC. |

PP (Polypropylene) |

Inexpensive, higher impact resistance in some grades, PP homopolymer can be brittle in cold. Wear resistant, flexible with high elongation. Resistant to acids and bases. Density less than water (floats) |

Integral hinges or living hinges, fans, snap-over lids (e.g., shampoo bottle tops), medical pipette tubing |

Thick sections in part geometry can void or show sink marks. Shrink and warp possible. If the part has living hinges that require higher stiffness, K-Resin is a good alternative. |

Polystyrene (PS) |

high optic clarity, good electric insulator |

plastic utensils, containers, optics, toys |

brittle, poor UV resistance, very susceptible to hydrocarbon solvents |

PEEK (Polyether Ether Ketone) |

High-temperature, high-performance, flame retardant; excellent strength and dimensional stability, good chemical resistance |

Bearings, piston parts and pumps; cable insulation; compatible with ultra-high vacuum applications. |

High-performance material, very expensive. Ultem (outlined below) is a slightly less-costly option, and PPSU is worth considering if price is a concern. |

PEI or Ultem (Polyetherimide) |

High-temperature, high-performance, flame retardant, excellent strength and dimensional stability, good chemical resistance. |

Medical and chemical instrumentation; tableware and catering; HVAC and fluid handling; electrical and lighting. |

Very expensive, though not as costly as PEEK. Look at PPSU as a possible alternative. |

PPSU (Polyphenylsulfone) |

High-temperature tolerance, dimensionally stable, high toughness. Resistance to radiation sterilization, as well as alkalis and weak acids |

Medical instrument components, sterilization trays, automotive fuses, interior aircraft parts, hot water fittings, sockets, and connectors. |

Thick sections could result in voids, bubbles or sink. Organic solvents and hydrocarbons can also attack PPSU. Colorant cannot be added to Protolabs-supplied PPSU resins |

PA (Aliphatic Polyamides) |

Wide variety. High strength and temperature tolerance when reinforced. Chemically resistant except to strong bases or acids |

Thin-walled features, combs, spools, gears and bearings, screws, structural parts (with glass), pump parts, under-hood components, cameras. |

Some nylons can be susceptible to warp due to non-linear shrink. Absorbs moisture, causing issues. |

PPA (Semi-aromatic Polyamides) |

less susceptible to moisture than aliphatic polyamides |

automtive housings, modules, valves, sports equipment |

susceptible to warp |

PBT (Polybutylene Terephthalate) |

Good electrical properties for power components and works well for automotive applications. Moderate to high strength depending on glass fill. Unfilled grades are tough and flexible. Good resistance to fuels, oils, fats, and many solvents. Doesn’t absorb flavors. Low creep. |

Slide bearings, gears and cams; coffee makers and toasters; hair dryer nozzles; vacuum cleaners; handles and knobs for electrical cookers. |

Glass-filled PBT resins are prone to warp, and have poor resistance to acids, bases, and hydrocarbons. Thin parts hard to fill with PBT. Nylons are good alternatives. |

PET (Polyethylene Terephtalate) |

similar to PBT, but stiffer and higher melting point |

similar to PBT |

similar to pbt |

LCP |

very easy flowing, good chemical resistance, high upper use temp, good electrical properties, low thermal expansion |

connectors, plugs, PCBs, sports equipment |

anisotropic properties and shrinkage, expensive |

PPO |

good electrical insulator, hot water / steam resistance |

sensor housings, pumps, connectors |

susceptible to stress cracking |

PPS |

very good chemical resistance, high upper use temp, great electrical properties |

electric components, automotive intakes / pumps / valves / sensor encapsulation |

desirable properties, such as chemical resistance rely heavily on proper crystallization during molding |

Related Blog

Automotive Die Casting and Casting Aluminum Alloys

Aluminum alloy has a series of excellent performance and highly efficient energy saving and environm…

12 Design tips for plastic injection parts

Choose the right material Choosing the right plastic material for injection molded parts can be tric…

Plastic Injection Molding Materials

Table of Contents Features And Differences Among Materials Crystalline plastics Non-crystalline plas…

“Customers are our partners, so we prioritize their needs.”

— CapableMaching