What is the Injection Molding

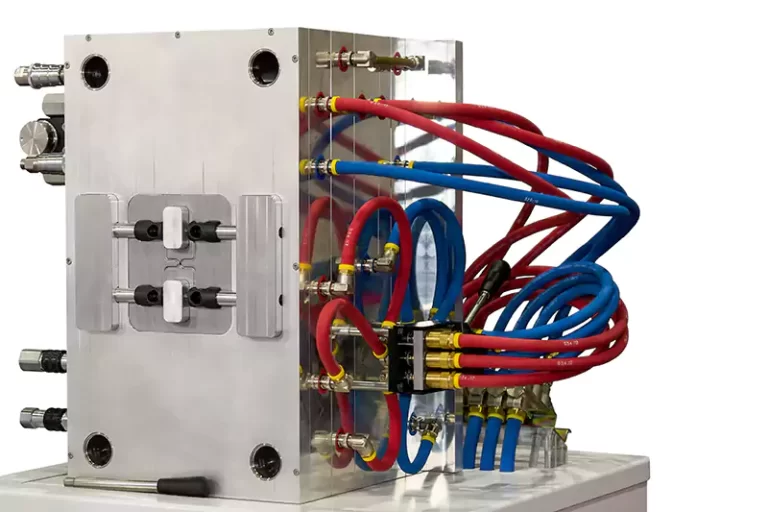

Process Clamping Injection Cooling Ejection Machine Types of machines Components of the machine Operating parameters Applications Automotive Consumer Goods Medical Packaging Aerospace Electronics Materials Used Polyethylene (PE) Polypropylene (PP) Polystyrene (PS) Acrylonitrile Butadiene Styrene (ABS) Polyamide (PA) Polycarbonate (PC) Polyethylene…