Rapid Prototyping

As the name suggested, rapid prototyping means to quickly make one piece or a few pieces of parts at the beginning of a project. To prototype quick, and cost-effective, 4 technologies are applied. CNC machining, rapid mold, 3D printing, and Urethane Casting. For CNC machining and rapid mold please check our rapid mold, CNC service page,. Below is an introduction of our 3D printing and Urethane Casting services.

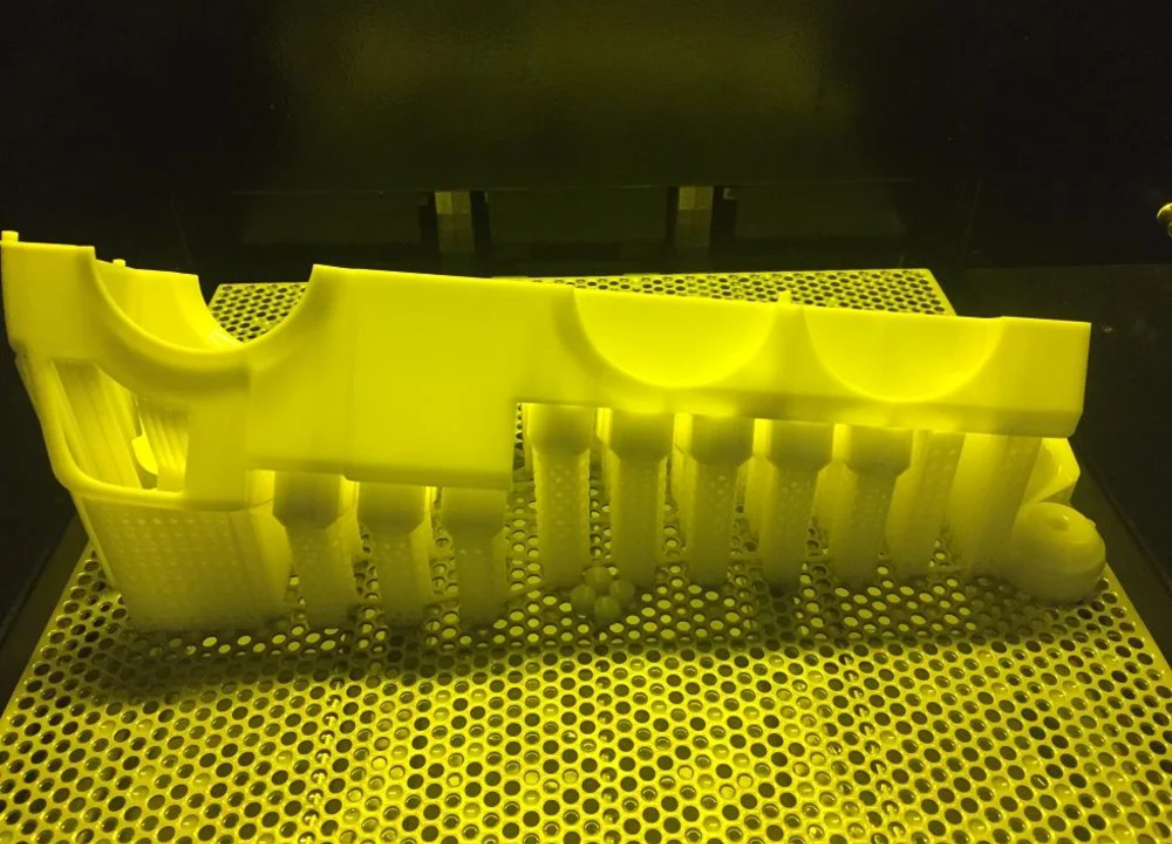

SLA

StereoLithography (SLA) is a 3D printing technology that converts liquid resins into solid parts, layer by layer, by selectively curing them using a ultraviolet (UV) light source. It is known for its high resolution and accuracy, fine details, and smooth surface finishes, making it ideal for creating prototypes, models, and production parts with intricate geometries.

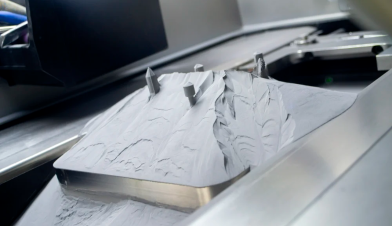

SLS

Selective laser sintering (SLS) utilizes laser to sinter plastic powders layer by layer and form the final product. Stronger materials (different grade of Nylon) are available for this method than SLA.

FDM

Fused Deposition Modeling (FDM) is the most widely used 3D printing technology which works by depositing melted filament thermoplastic material over a build platform layer by layer until you have a completed part. Compare with SLS and SLA, it can make rather large parts, and almost all thermoplastic can be utilized in this method.

MJF

Jet Fusion (MJF) is an industrial 3D printing process that produces functional nylon prototypes and end-use production parts in as fast as 1 day, with quality surface finishes, fine feature resolution, and consistent mechanical properties. Various type of nylon can be used in this method. It is a good choice when the part’s strength and function are the main concerns.

SLM

Selective Laser Melting (SLM) is a specific 3D printing technique that utilizes high power-density laser beams to fully melt and fuse metallic powders to produce near net-shape parts with near full density. SLM is most useful for creating parts made of pure metals, as the higher temperatures can fully fuse the metal powders together without compromising their mechanical properties. The technology has revolutionized the additive manufacture of metal parts and is regarded as a premier metal 3D printing technology.

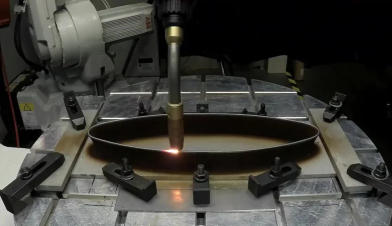

WAAM

Wire Arc Additive Manufacturing (WAAM) is a metal 3D printing technology belonging to the Direct Energy Deposition (DED) family of Additive Manufacturing processes which is executed by depositing molten metal layers on top of each other until a desired shape is built, and is predominantly utilized in aerospace, marine and automotive industries. It is particularly cost-effective for intricate large parts like air plan engine parts.

Urethane Casting

Urethane casting is a rapid prototyping technology that uses silicone molds to create production-quality, short-run parts as an economical alternative to low-volume injection molding. It is a versatile process that can produce complex, rigid, flexible, and rubber parts with consistent mechanical properties. It is particularly cost effective for small volume production from a couple of dozens to a few hundred pieces.

Specifications

| Technology | Cost | Material | Best For | Size | Leading Time |

|---|---|---|---|---|---|

| SLA | $ | White,Black,Yellow,Transparent photosensitive resin | Appearance Prototypes | 500 × 500 × 600 mm | 1-3 days |

| SLA-Large | $ | White,Black,Yellow,Transparent photosensitive resin | Appearance Prototypes | 800 × 1200 × 1700 mm | 3-5 days |

| SLS | $$ | White,Black PA12, PA12+GF30%, PA12+Alu 40% | Function Prototypes | 500 × 500 × 600 mm | 3-5 days |

| MJF | $$ | PA11,PA12,PA12+GB40% | Function Prototypes | 380 × 284 × 380 mm | 3-5 days |

| FDM | $$ | PLA,PC,ABS,Nylon,ULTEM,Multi Colors | Appearance and Function Prototypes | 500 × 500 × 600 mm | 3-5 days |

| SLM | $$$$$ | Stainless Steel, Ni-Cr, Co-Cr, AlSi10Mg, TC4, Tin Bronze | Intricate Metal prototypes | 500 × 500 × 600 mm | 3-5 days |

| WAAM | $$$$ | Alu 4047, 5083,4043,Cu alloys,TC4,Steel 4043 | Large Metal prototypes | N/A | 5 days |

| Urethane Casting | $$ | ABS-like, Nylon-like, PC-like,POM-like,TPU-like,Silicon-like | Small volume or Bridge production | N/A | 5 days |

CapableMachining Rapid Prototyping Services

Our seasoned engineers, armed with cutting-edge technology, deliver precision-engineered prototypes in record time. We don’t just offer a service, we provide a partnership, offering expert consultation every step of the way. With CapableMachining, you gain not just quick delivery, but also a wealth of experience and unwavering dedication to bringing your vision to life. Click the button below, let us take your projects from concept to reality, faster than ever before.