All You Need to Know About CMM Machines

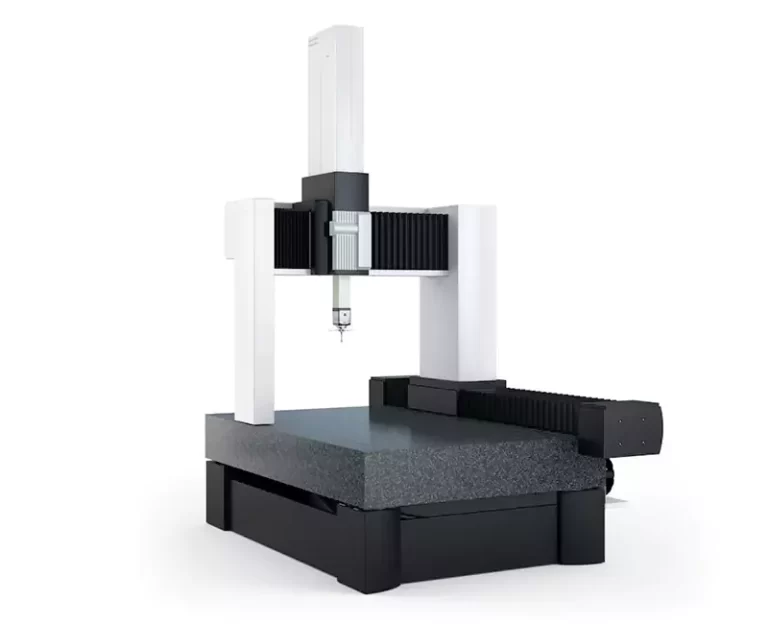

What Is a CMM Machine? A Coordinate Measuring Machine (CMM), also known as a CMM, is an apparatus designed to measure the geometries of physical objects. CMMs employ a probing system to detect individual points on object surfaces. The first-ever…