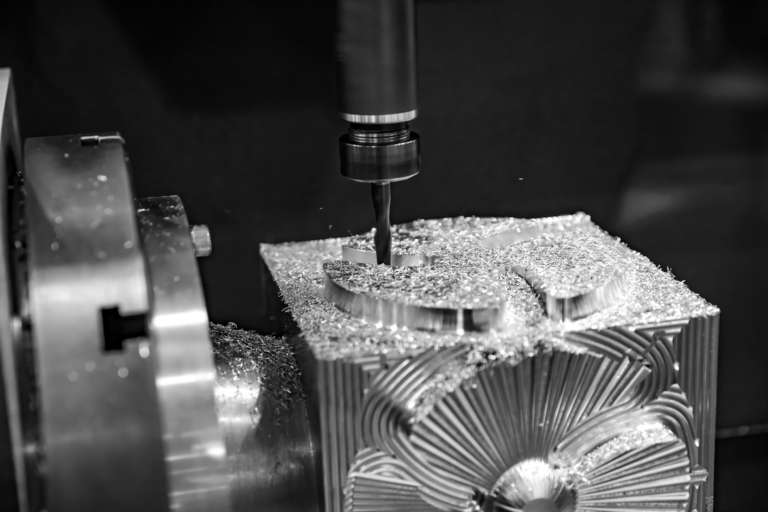

How CNC Milling Works

Table of Contents What is CNC Milling The CNC milling process CNC Milling Machines Vertical milling machines Horizontal milling machines Gantry milling machines Advantages of CNC Milling Machine Types of CNC Milling Face milling Plain milling Angular milling Form milling…