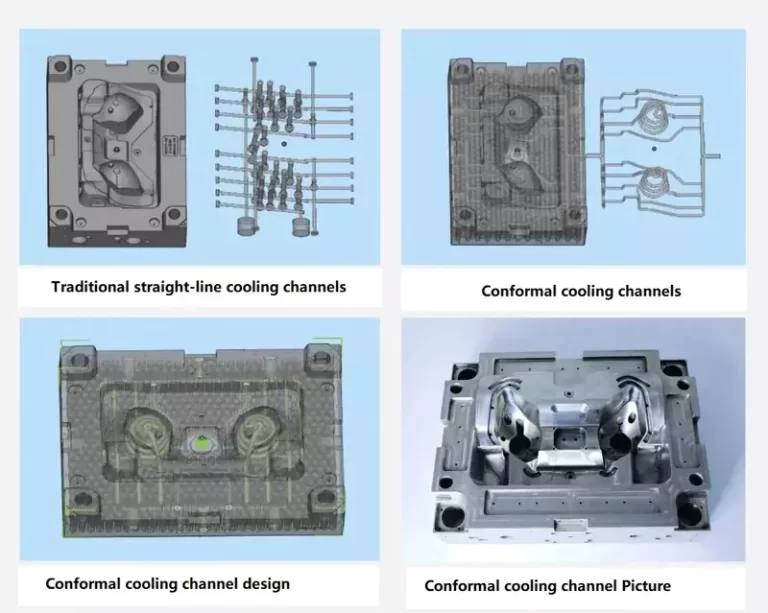

Metal 3D printing is employed for conformal cooling channels in injection molds

As an integral part of injection molds, the water channel is located within the mold to guide the flow of cooling water, controlling temperatures, and expediting the cooling process. The mold cooling system is a crucial factor influencing the quality…