Revolutionizing Injection Molding: The Power of Automation in Improving Efficiency and Reducing Costs

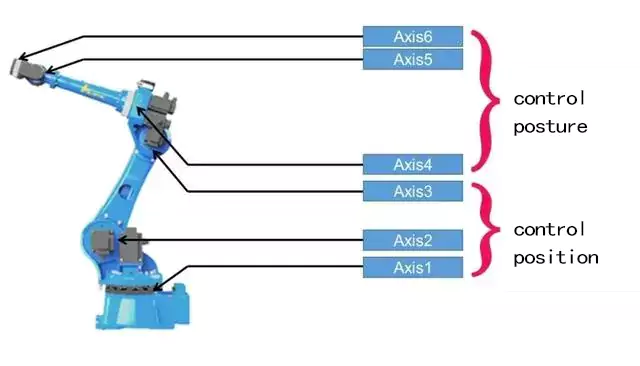

Automation in Injection Molding Automation in Injection Molding Types of Automation Types of Automation 1. Six-Axis Robots 2. SCARA Robots 3. Cartesian Robots Impact on Efficiency How Automation Improves Efficiency 1. Real-World Examples Cost Reduction in Injection Molding How Automation…