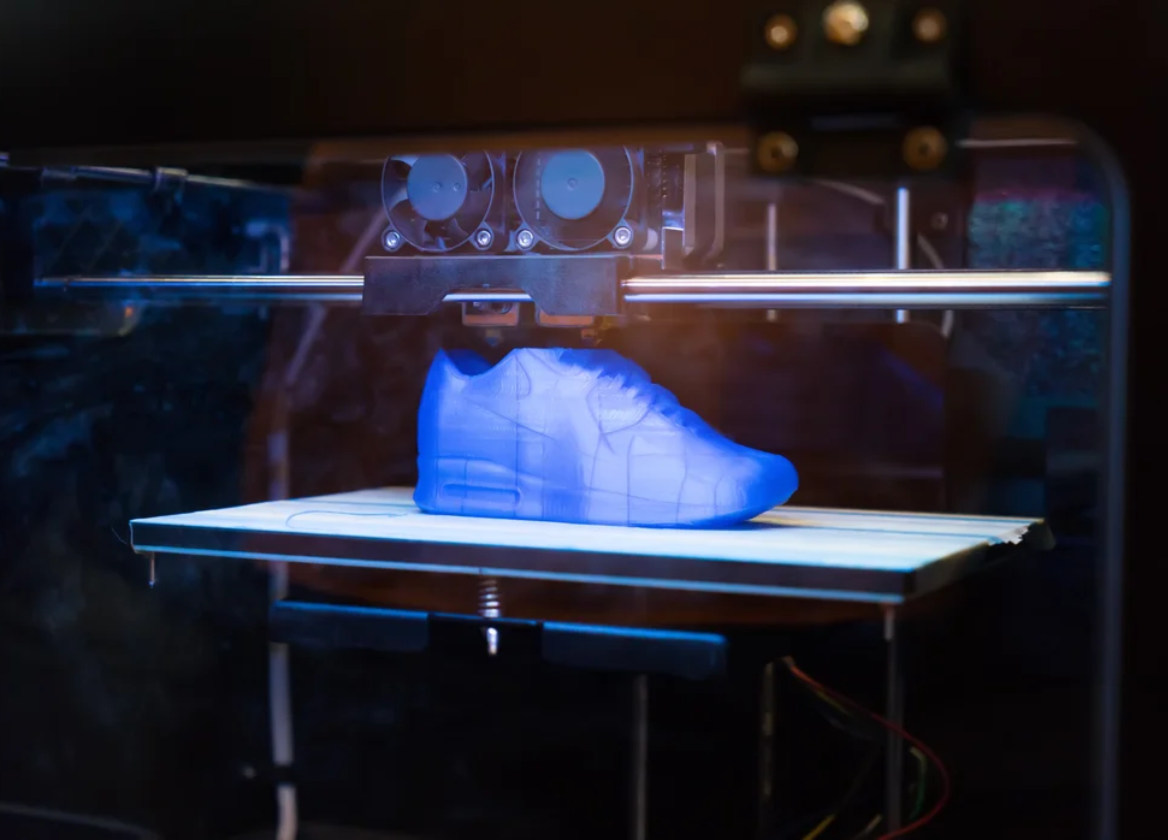

FDM stands for Fused Deposition Modeling

Which is a type of 3D printing technology that uses thermoplastic filament to create 3D objects. The filament is fed into the printer’s nozzle, heated up, and then extruded onto the build platform to create the object layer by layer.

The FDM Process: Step by Step

Advantages of FDM Printing

Material availability

FDM printers can use a wide range of materials, including ABS, PLA, PET, Nylon, TPU, and more. These materials have various properties that make them suitable for different applications, such as outstanding thermal and chemical resistance and excellent strength-to-weight ratios.

User-friendly

FDM printers are easy to use and require minimal setup and calibration. They are also relatively safe to operate, as the process does not involve any harmful chemicals or high temperatures.

Speed

FDM printing is a relatively quick process, and parts can be printed in a matter of hours depending on the size and complexity of the object.

Large build volume

FDM printers can produce objects in a range of sizes, from small, intricate parts to large-scale prototypes and models.

Design flexibility

FDM printing allows for a high degree of design flexibility, with the ability to print complex geometries and internal structures.

Environmental benefits

FDM printing is an environmentally friendly manufacturing process, as it generates very little waste and uses only the necessary amount of material to create each part.

FDM Material available in CapableMachining

| Material | Color(s) | Tensile Strength (MPA) | Elongation at Break | Tempature Resistancce |

|---|---|---|---|---|

| ABS-M30 | Black, Dark Grey, Ivory, White | 32 MPa-28 MPa | 7%-2% | 96 °C |

| ABSi | Translucent | 37 MPa | 4.40% | 86 °C |

| ASA | Black, Gray, Green, Ivory, White | 27 MPa | 9%-3% | 98 °C |

| Nylon 12 | Black | 49.3 MPa-41.8 MPa | 30%-6.5% | 91.9 °C |

| PC-ABS | Black | 41 MPa | 6% | 110 °C |

| PC | White | 57 MPa-42 MPa | 4.8%-2.5% | 138 °C |

| PC-transparent | Translucent Natural, White | 57 MPa | 4% | 133 °C |

| PLA | Black, White | 50 MPa-37 MPa | 2.9%-1.9% | 55 °C |

| ULTEM 9085 | Black, Tan | 47 MPa-33 MPa | 5.8%-2.2% | 153 °C |

| ULTEM 1010 | Amber (Natural) | 64 MPa-41 MPa | 3.3%-2.0% | 216 °C |

CapableMachining’s FDM 3D printing services

At CapableMachining, we pride ourselves on our high-quality FDM 3D printing services. Our experienced team of engineers and technicians use state-of-the-art equipment and software to ensure that every part is produced to the highest standards of quality and accuracy. Click the button below to your designs into reality.