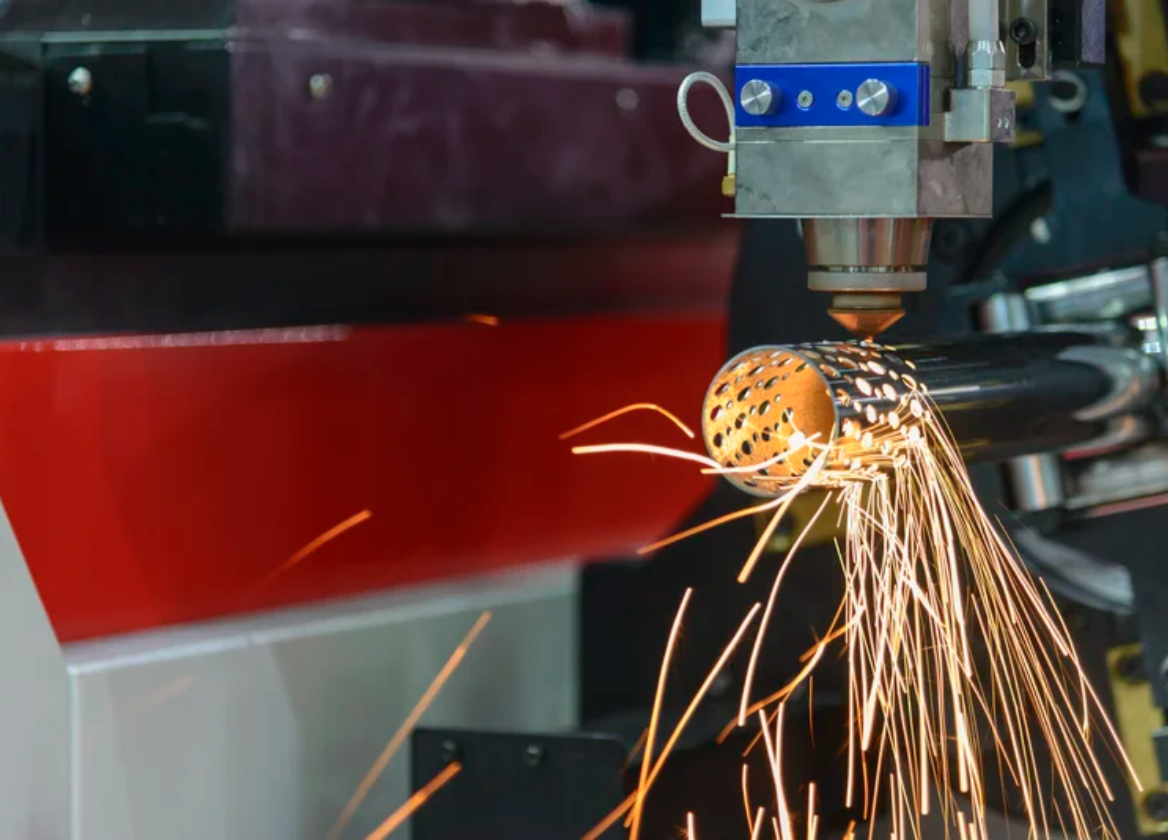

Laser Cutting

We use fiber laser cuttings. Fiber laser cutting is 2~4 times faster than traditional CO2 laser cutting. Fiber lasers typically produce cleaner cuts than CO2 lasers, especially when cutting metals. This is because fiber lasers have a smaller wavelength (0.7 to 2.2 micrometers)than CO2 lasers (1.06 micrometers), allowing for a smaller focal diameter. The result is less heat affected zones (HAZ) and a narrower kerf, which leads to clean, precise cuts with smooth edges. A narrower kerf is beneficial because it allows for more precise cuts and less wasted material.

Advantages of Laser Cutting

Precision

Laser cutting is known for its extremely high precision, with accuracy up to 0.005 inches (0.127 mm) and a positioning accuracy of +/- 0.0005 inches (0.0127 mm).

Speed

Laser cutting has a high cutting speed, with the ability to cut up to 20 meters per minute, depending on the material and thickness.

Repeatability

Laser cutting provides consistent, repeatable cuts, ensuring uniformity in the final product.

Flexibility

Lasers can cut a wide variety of materials, including metals, plastics, wood, fabric, and more, making it a versatile cutting method.

Contactless cutting

Laser cutting is contactless, meaning there is no physical contact between the laser and the material being cut, which reduces the risk of material distortion or damage.

Low heat affected zone (HAZ)

Laser cutting produces a small heat-affected zone compared to other thermal cutting methods, minimizing the risk of material warping or distortion.

Minimal material waste

Laser cutting produces minimal material waste due to the narrow kerf width, which allows for efficient use of materials and reduced production costs.

Laser Cutting Specifications

| Items | Specifications |

|---|---|

| Laser power | up to 20 kW |

| Cutting speed | up to 20 meters (785 in) per minute |

| Cutting thickness | up to 20 mm (0.787 in) for metals, and up to 30 mm (1.18 in) for plastics |

| Kerf width | typically less than 0.1 mm (0.004 in) |

| Positioning accuracy | +/- 0.05 mm 0.02 in) |

| Maximum workpiece size | up to 6 meters x 2.5 meters (236 x 98 in) |

| Laser beam diameter | typically 0.1-0.4 mm (0.004~0.016 in) |

| Minimum part size | 10 mm (0.40 in.) |

| Minimum feature size | 2X thickness with a minimum of 1 mm (0.04 in.) |

| Tolerance Standard | ISO 2768 C Typically +/- 0.2mm (0.008 in). |

| Leading Time | Typically 3~5 days |

Laser Cutting Materials

Metal

The following is a list of metal material supported by CapableMachining’s laser cuttings. Other metal material may also be available up to request.

Plastic

The following is a list of plastic material supported by CapableMachining. Other plastic material may also be available up to request.