MJF stands for Multi Jet Fusion

Which is a 3D printing process developed by HP. It is an industrial 3D printing technology that uses a combination of thermal energy and binding agents to create 3D objects from powdered thermoplastics.

The MJF Process: Step by Step

Advantages of MJF Printing

Speed

MJF is one of the fastest 3D printing technologies available, with the ability to produce parts up to ten times faster than other 3D printing technologies like FDM (Fused Deposition Modeling).

High-Quality Parts

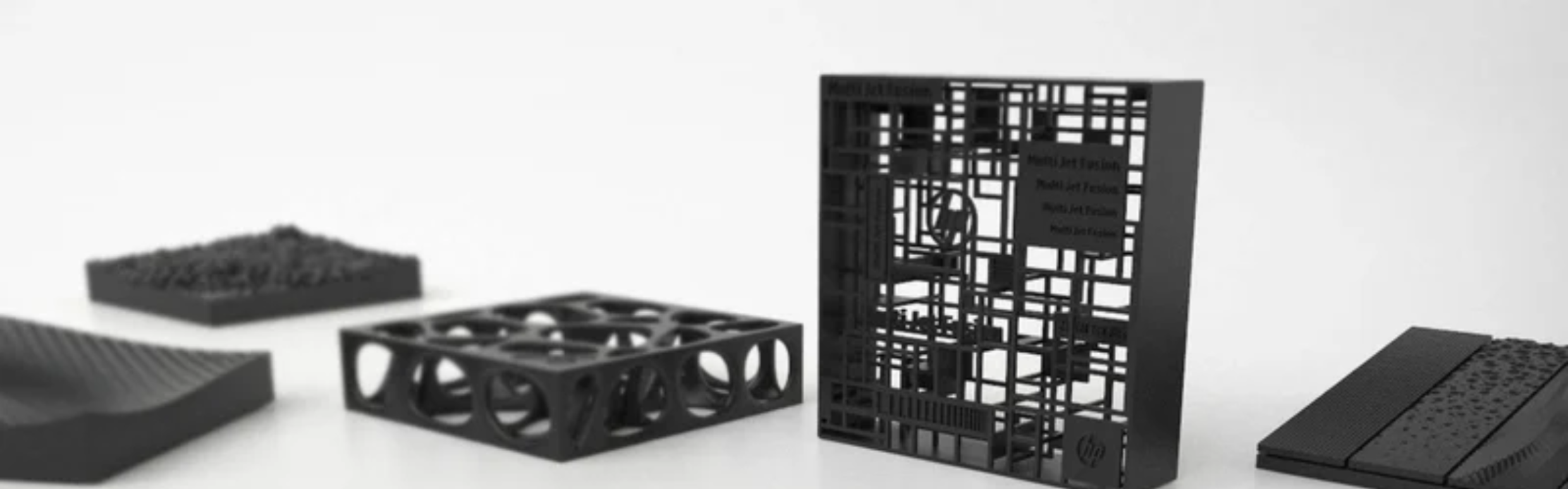

MJF produces high-quality parts with fine details and textures, making it ideal for complex geometries and intricate designs.

Cost Efficiency

MJF can produce parts more cost-effectively than other methods, especially for small-to-medium-sized batches of production parts, especially when you need better function and better strength prototypes.

Reduced Waste

MJF produces less waste than other 3D printing technologies, such as SLS, since it only uses the amount of powder required to create the part. This can help to reduce material costs and improve sustainability.

Post-Processing Efficiency

MJF produces parts with a smooth surface finish, which can reduce the amount of time and effort needed for post-processing finishing tasks like sanding or polishing.

MJF Material available in CapableMachining

| Material | Color(s) | Tensile Strength (MPA) | Elongation at Break | Tempature Resistancce |

|---|---|---|---|---|

| PA11 | Black, Grey | 52 Mpa | 50% | 54°C |

| PA12 | Black, Grey | 48 Mpa | 20% | 95°C |

| PA12 GB 40% | Black, Grey | 30 Mpa | 6.50% | 120°C |

CapableMachining’s cutting-edge MJF (Multi Jet Fusion) 3D printing service – the perfect technology to bring your most innovative ideas to life.

With our advanced MJF service, we can create highly detailed and complex parts in a fraction of the time compared to traditional manufacturing methods. Our team of experts work closely with you to ensure your project meets all specifications and exceeds your expectations. Plus, with industrial grade nylon, we have a solution for a lot of applications. The cost-effective and sustainable nature of MJF means you can produce higher quality parts with less waste, and at a fraction of the cost of traditional manufacturing. Whether you need to prototype, manufacture small batches, or create a full production run, CapableMachining’s service has you covered. Click the button blow to realize your design.