What is Plasma?

Plasma or ionized gas is considered the fourth state of matter (after solid, liquid, and gas). While not common on Earth under normal conditions, it’s estimated that over 99% of the visible universe is in the plasma state, including stars and interstellar space.

The principle of forming Plasma gas involves a process known as ionization. Ionization is the process by which an atom or a molecule acquires a negative or positive charge by gaining or losing electrons. This typically occurs when an atom or molecule interacts with energy, such as heat or light, or with another atom or molecule.

Plasma Cutting Process: Step by Step

Here’s a step-by-step explanation of how ionization forms an ionized gas, also known as plasma:

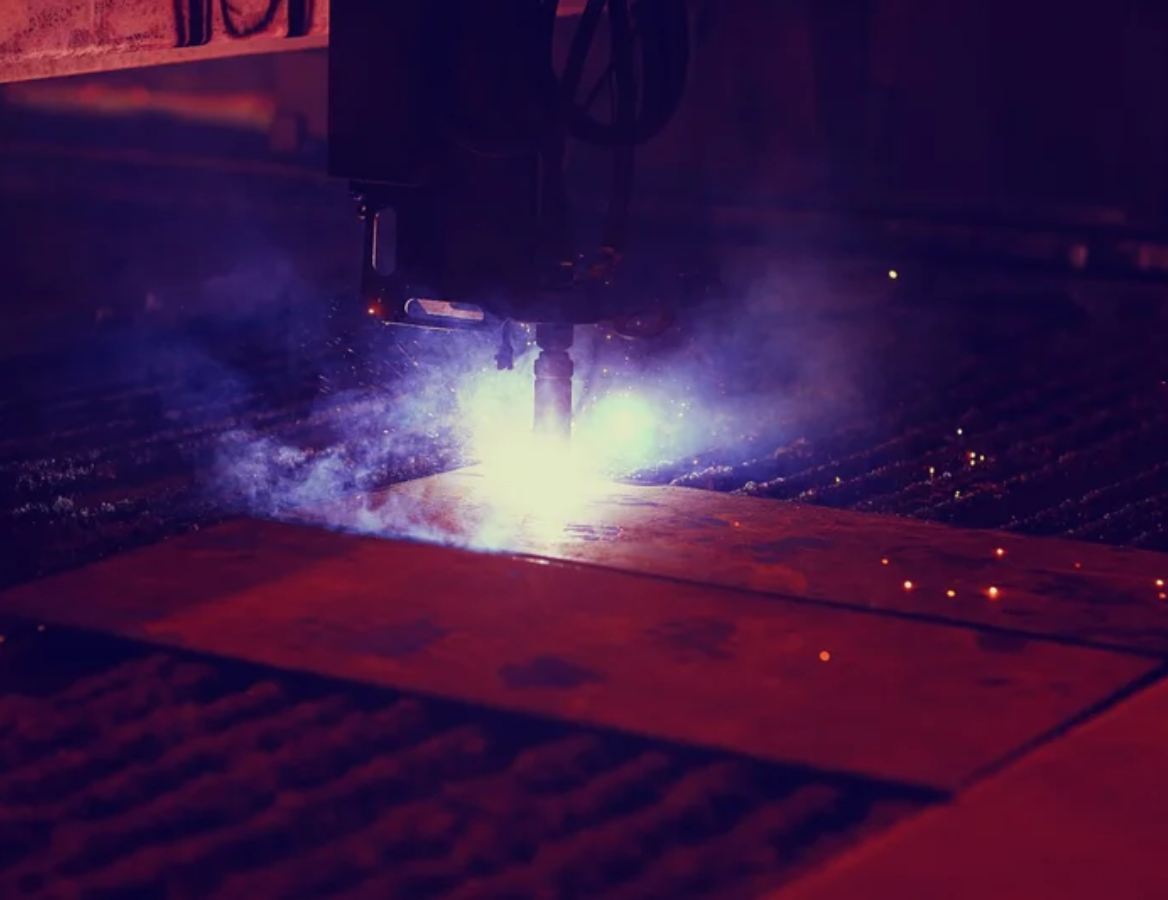

How plasma cutting works?

Plasma cutting tool is a machine that uses ionized gas (plasma) to cut through conductive materials. The basic principle behind plasma cutting is that when a gas is heated to a high temperature and ionized, it becomes electrically conductive, allowing an electric arc to be formed through the gas.

When the plasma cutting tool is turned on, the gas supply delivers the plasma gas to the plasma torch. The gas then flows through the nozzle of the torch, where it is ionized by the electrical current flowing through the electrode (cathode).

This creates a plasma arc that is directed toward the material being cut (anode). As the plasma arc comes into contact with the material being cut, its high temperature and velocity cause the material to melt and vaporize. The gas flowing through the nozzle of the plasma torch also blows away the molten material, leaving a clean, smooth cut edge.

Plasma cutting advantages

Cutting thickness

Plasma cutting is an effective method for cutting thicker materials, typically up to 6 inches thick or more. Laser cutting, on the other hand, is better suited for thinner materials up to 1 inch thick.

Cost

Plasma cutting systems are generally less expensive than laser cutting systems, making them a cost-effective option for many businesses.

Cutting speed

Plasma cutting is generally faster than laser cutting, particularly when cutting thicker materials. This can help improve productivity and reduce lead times.

Portability

Plasma cutting systems are smaller and more portable than laser cutting systems, making them easier to move between job sites.

Minimal maintenance

Plasma cutting systems require less maintenance than laser cutting systems, as they have fewer moving parts and do not require regular alignment.

Plasma cutting disadvantages

Limited accuracy

While plasma cutters are highly versatile and can cut various types of materials, they may not be as accurate as other cutting methods such as laser cutting. This can be a disadvantage for applications that require high precision.

Rough edges

Plasma cutting can sometimes result in rough or jagged edges, particularly when cutting thicker materials. This can make post-processing and finishing more difficult and time-consuming.

Large heat-affected zone

Plasma cutting has a larger heat-affected zone, in the zone, metal’s heat treatment status might change.

Limited Material

Plasma only works with conductive material, it can not cut material like plastic, stone or wood.

Plasma Cutting Specifications

| Items | Specs |

|---|---|

| Thickness | Up to 50mm (2 in) |

| Tolerance | Material thickness and material nature affect tolerance greatly, typically 0.5~1mm |

| Minimum Part Size | 25mm |

| Kerf (slit size) | 0.5mm ~2mm |

| Edge Condition | Plasma edge will have vertical striations and be tapered. Upper edges may have a rounded area with top splatter. |

| Max Cutting Size | 2000mm x 3000mm |

| Lead Time | 3~5 days |

Materials for Plasma Cutting

The following is a list of metal material supported by CapableMachining’s CNC plasma cuttings. Other metal material may also be available up to request.