SLA stands for Stereolithography Apparatus

It’s a type of 3D printing technology that uses a light source—usually an ultraviolet (UV) laser—to convert liquid materials, specifically photosensitive resins, into solid parts, layer by layer. Known for its high resolution, accuracy, and ability to produce fine details, SLA is often the go-to choice for creating prototypes, models, and production parts with intricate geometries. SLA is probably the most popular industry grade 3D printing technology due to its high production speed.

The Core Material: Photosensitive Resin

The primary material used in SLA is a photosensitive resin. This thermoset polymer remains in a liquid state until it’s exposed to light at a specific wavelength. The resin contains special molecules called photoinitiators that absorb this light and release energy. This energy triggers a chemical reaction known as photopolymerization, causing the resin to harden and change from a liquid to a solid state.

SLA Process: Step by Step

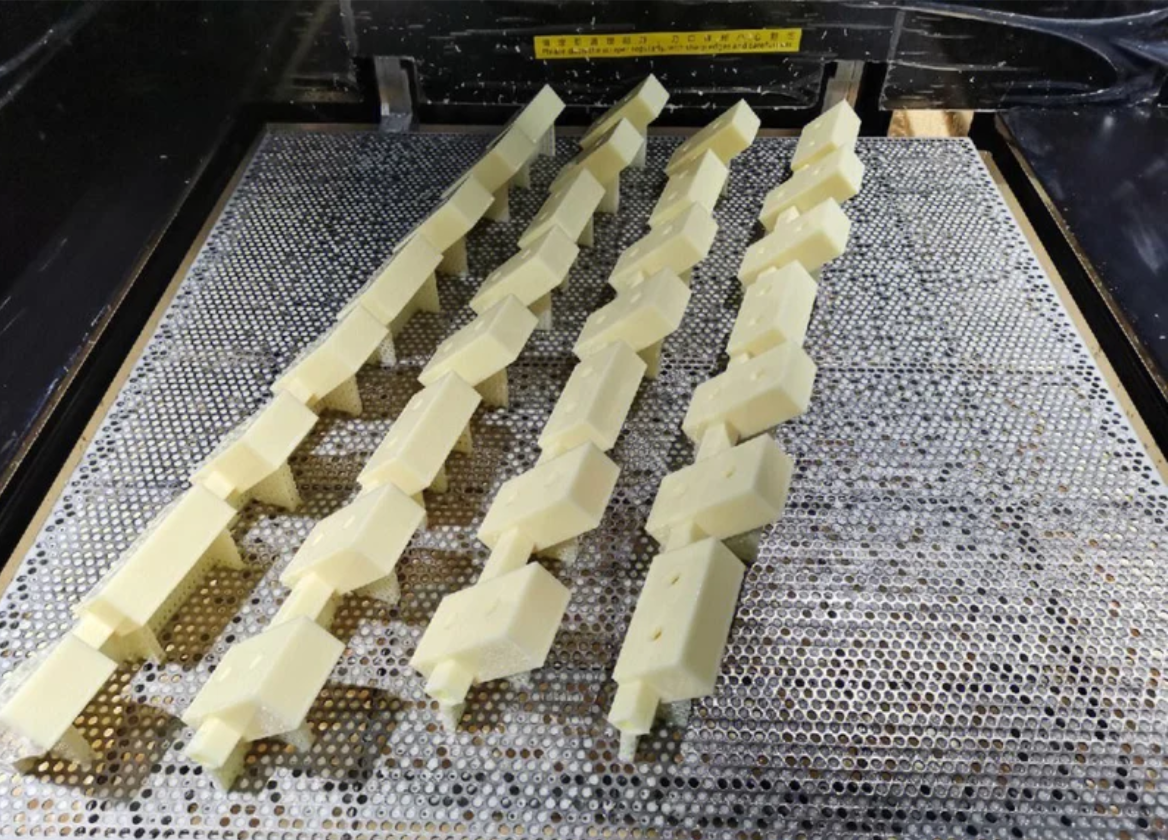

CapableMachining SLA Materials

| Material | Color | Temperature resistance | Paintable | Specifications |

|---|---|---|---|---|

| White Resin JS-UV-HP-02 | White | 30℃ – 40℃ | Y | Hardness:76-85 Viscosity:360-420 cps(25℃) Density:1.11-1.14g/cm3(25℃) Layer Height:0.05-0.12mm Bending strength: 60-75Mpa Tensile Strength:25-30Mpa |

| Yellow Resin JS-UV-2016-XLST | Yellow | 30℃ – 40℃ | Y | Hardness:76-85 Viscosity:360-400 cps( 25 ℃) Density:1.11-1.14g/cm3(25℃) Layer Height:0.05-0.12mm Bending strength: 60-75Mpa Tensile Strength:25-30Mpa |

| Black Resin | Black | 30℃ – 40℃ | Y | Hardness:76-85 Viscosity:360-400 cps( 25 ℃) Density:1.11-1.14g/cm3(25℃) Layer Height:0.05-0.12mm Bending strength: 60-75Mpa Tensile Strength:25-30Mpa |

| Translucent Resin | Colorless | 30℃ – 40℃ | Y | Hazy feeling, the surface texture is similar to that of white resin |

| Translucent Resin | Colorless | 30℃ – 40℃ | Y | Hazy feeling, the surface texture is similar to that of white resin |

Transform Your Designs into Reality with CapableMachining

High-Precision SLA 3D Printing Services

At CapableMachining, we bring your designs to life with exceptional detail and precision. Our state-of-the-art Stereolithography (SLA) technology enables us to convert your digital models into high-quality physical objects.

Superior Accuracy & Detail

Our SLA process ensures every part of your design is captured with the highest level of detail.

Smooth Surface Finish

With SLA and our outstanding Post processing, we can achieve smooth, clean surfaces right out of production.

Wide Range of Materials

Choose from a variety of photosensitive resins to meet your specific project requirements.

Fast Turnaround

Our efficient process means you’ll have your parts in hand quickly, keeping your project on schedule. Leading time as fast as 1 day.