SLM

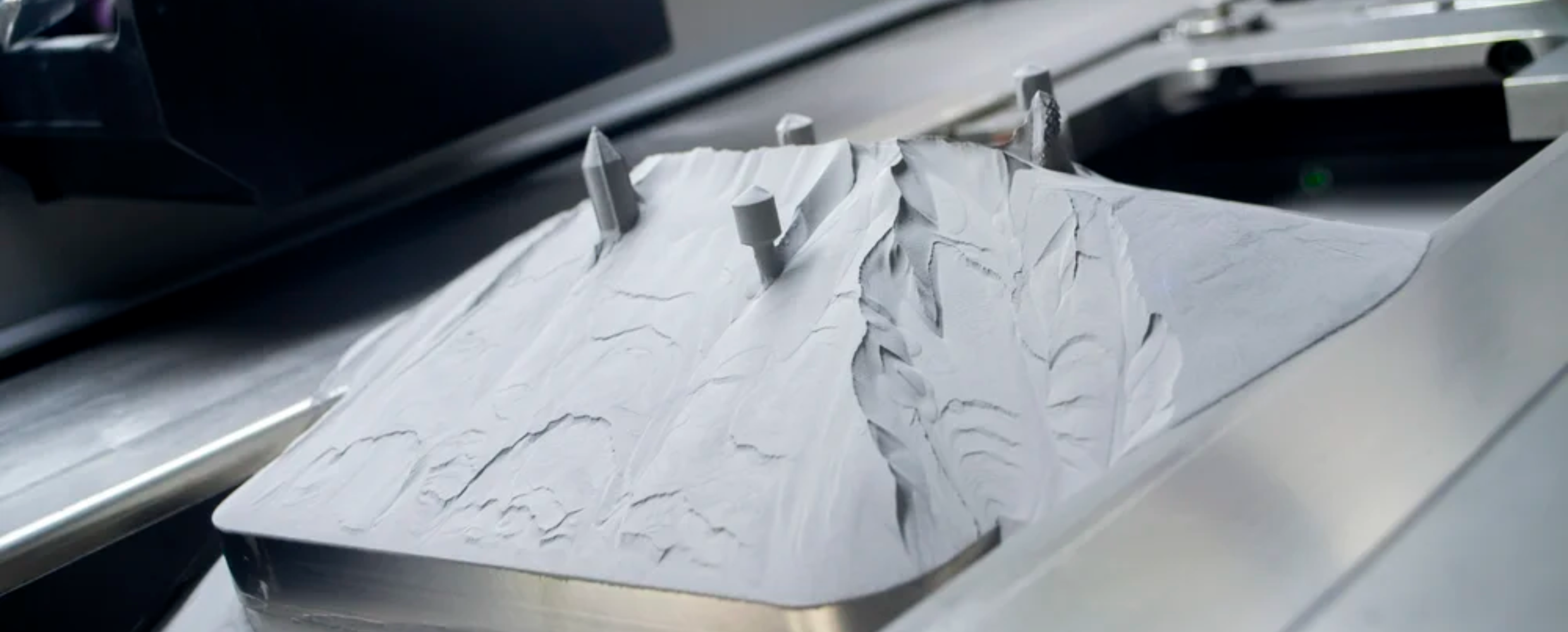

SLM (Selective Laser Melting), also known as laser powder bed fusion (LPBF) or direct metal laser melting (DMLM), is an advanced 3D printing technology that uses lasers to melt metallic powders layer by layer until the final part is complete. This process creates highly complex and intricate metal parts with superior strength and durability. One of the main benefits of SLM is its ability to produce parts with geometries and internal structures that would be impossible to achieve through traditional manufacturing methods. This opens up a whole new realm of possibilities for designers and engineers, particularly in aerospace, automotive, medical, and other industries where highly complex parts are required. Another advantage of SLM is the quality of the final product. The metallurgical properties of SLM-produced parts are often superior to those produced through casting. This makes SLM an ideal choice for manufacturing components that require high strength, corrosion resistance, or other specialized properties.

The SLM Process: Step by Step

Advantages of SLM Printing

Design flexibility

SLM allows for the creation of complex and intricate designs that would not be possible with traditional manufacturing processes. This is because SLM builds parts layer by layer, which means it can produce parts with geometries and internal structures that would be impossible to achieve through other methods.

Material options

SLM can be used with a wide range of metallic materials, including aluminum, titanium, stainless steel, and cobalt-chrome alloys. This provides designers and engineers with a broad range of material options for the parts they need to create.

High strength and durability

SLM-produced parts have excellent mechanical properties, including high strength, durability, and wear resistance. This makes them ideal for use in applications that require high-performance parts.

Reduced waste

SLM produces minimal waste during the manufacturing process, which makes it more environmentally friendly than traditional manufacturing methods. It also reduces the amount of material used, which can result in cost savings.

Faster production

SLM can produce parts quickly and efficiently, which means that designers and engineers can get their parts faster than they would with traditional manufacturing processes. Additionally, SLM is capable of producing single-piece parts, which eliminates the need for assembly.

Customization

SLM enables the customization of parts, which can be tailored to meet specific design requirements. This provides greater flexibility in product design and allows for the creation of unique parts that are specific to a particular application.

SLM Material available in CapableMachining

| Material | Specs | Features |

|---|---|---|

| Stainless Steel-316L | Density:≥7.90 g/cm3 Tensile Strength:480-580MPa elongation after break:≥40 % Vickers Hardness:≥180 HV | High Hardness and Toughness Strong corrosion resistance better machinability Can be high gloss polished |

| Nickel-Chromium-In 718 | Density:≥8.18 g/cm3 Tensile Strength:1230-1430MPa elongation after break:12%-20% Vickers Hardness:≥410 HV | Ease of processing It has high Tensile Strength, fatigue strength, Creep strength and breaking strength High oxidation resistance at 1000°C Stable chemical properties at low temperatures Good welding performance, strong corrosion resistance |

| Cobalt Chromium-CoCr | Density:≥8.35g/cm³ Tensile Strength:980-1080MPa elongation after break:7%-10% Vickers Hardness:≥350HV | Excellent finished surface high toughness high strength Excellent biocompatibility good corrosion resistance |

| Aluminum alloy-AlSi10Mg | Density:≥2.65 g/cm³ Tensile Strength:400-460 MPa elongation after break:≥5 % Vickers Hardness:≥120 HV | Build parts with excellent mechanical properties, Such as Hardness and Tensile Strength excellent corrosion resistance Good thermal and electrical conductivity High dynamic toughness |

| Titanium alloy-TC4 | Density:≥4.40g/cm³ Tensile Strength:1050-1150MPa BS elongation after break:4%-8% Vickers Hardness:≥310 HV | High strength to mass ratio Strong corrosion resistance Good biocompatibility and osseointegration Small thermal expansion, low thermal conductivity better machinability |

| Tin Bronze alloy-CuSn10 | Density:≥8.78 g/cm3 Tensile Strength:460-520MPa elongation after break:≥20 % Vickers Hardness:≥115 HV | Seawater cavitation resistance, good corrosion resistance Good wear resistance better machinability Good thermal conductivity non-magnetic |

CapableMachining’s High-quality SLM service

CapableMachining’s team of experienced engineers and state-of-the-art machines can create highly complex and intricate metal parts that meet even the most demanding specifications. We pride themselves on providing exceptional customer service and support throughout the entire manufacturing process, from design to production to post-processing.

If you’re looking for a reliable and high-quality SLM service provider, CapableMachining is an excellent choice. Contact us by click the button below. Send us your design, we will handle the rest.