WAAM

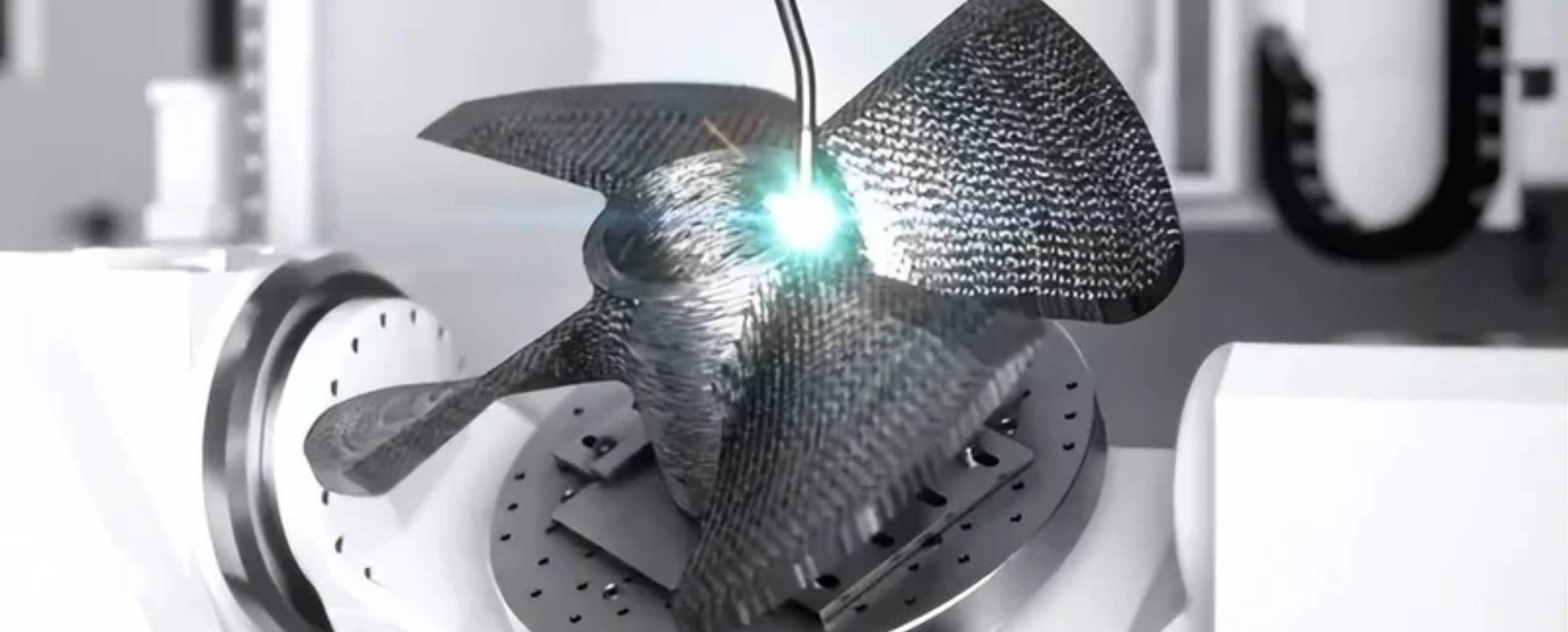

WAAM stands for Wire Arc Additive Manufacturing. It is an additive manufacturing process that uses a wire as feedstock and an arc welding process to 3D print metal parts. The process is based on traditional joining methods of welding and has been around since the 1990s. The basic principle of the WAAM process involves using a robotic-controlled welding torch to heat the wire feedstock and melt it into a molten pool. The molten pool is then deposited layer by layer onto a build platform, where it cools and solidifies to form a solid part. In other term, WAAM is a CNC arc welding process that can be performed with or without a substrate.

The WAAM process offers several advantages over traditional manufacturing methods. It allows for the creation of complex and intricate designs, reduces material waste. The precision of WAAM is 1~3mm. It is also flexible in terms of the types of metals that can be used as feedstock, including aluminum, copper, nickel, and titanium. This process is particularly cost-effective for single piece or small batches of large parts.

Some of the applications of WAAM include aerospace, automotive, and marine industries. In the aerospace industry, WAAM can be used to produce structural components such as wings, fuselage sections, and engine parts. In the automotive and marine industries, WAAM can be used to produce large, complex components with high precision.

WAAM Material

Theoretically all material the weldable can be used in WAAM. Most commonly Alu 4047,Alu 4043, Alu5083, Copper, Steel 4043, TC4. Etc. At CapableMachining, we pride ourselves on providing excellent customer service and support throughout the entire manufacturing process. We work tirelessly to ensure that our clients receive the highest quality parts on time and within budget.

If you’re looking for a reliable and efficient WAAM service provider, look no further than CapableMachining. Click the button below, we make large parts, we make good parts.