Cold or Hot Runner: Choice for Better Efficiency Injection Molding

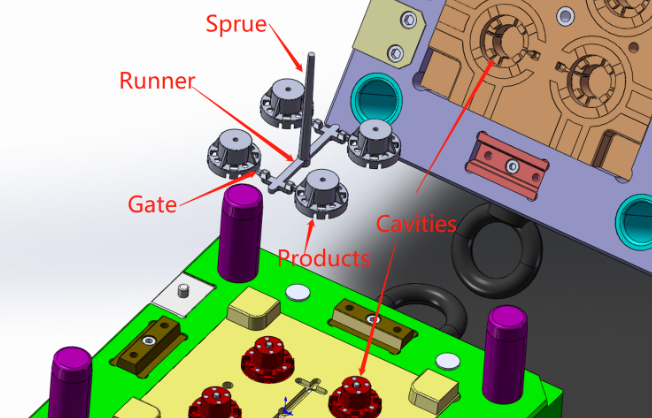

I. Introduction II. Cold Runner Systems Two-plate mold Three-plate mold Cold Runner Systems’ Pros and cons: III. Hot Runner Systems The insulated hot runner The insulated hot runner Short Comings The internally heated runner The internally heated runner Short Comings…