Cold or Hot Runner: Choice for Better Efficiency Injection Molding

I. Introduction

Plastic injection molding is a manufacturing process used to produce parts by injecting molten plastic into a mold, where it cools and solidifies into the desired shape.

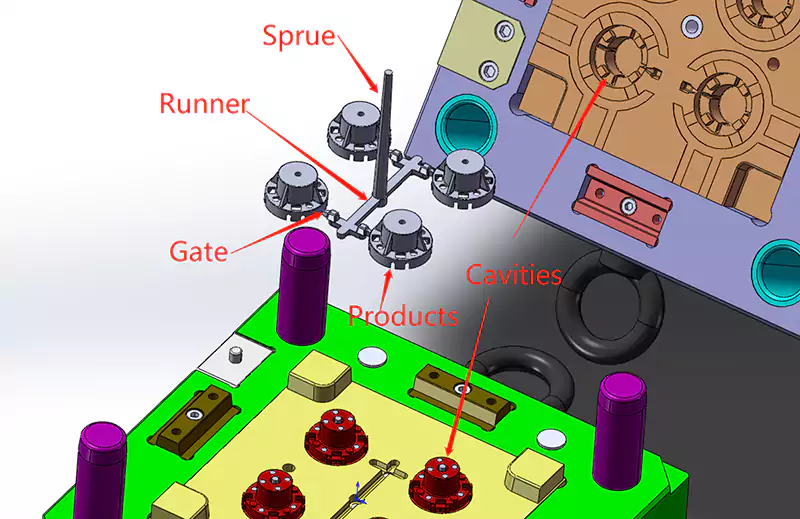

A runner in injection molding refers to the channel that connects the sprue (where the molten plastic material is first introduced into the mold) to the individual cavities (where the final part shape is formed). In other words, it is the pathway that directs the molten plastic from the injection machine’s nozzle into the mold cavities.

The runner system is an important part of injection molding because it lets the plastic material flow evenly and consistently into the mold cavities. There are two main types of runner systems: cold runners and hot runners. This article is going to explain the structures of these two systems, how they work, as well as their advantages and disadvantages.

II. Cold Runner Systems

The cold runner plastic injection mold is divided into two types: the two-plate mold and the three-plate mold.

Two-plate mold

A two-plate injection mold is the most common because of its simple structure. It takes 2 mold plates to form the mold cavity. The runner in the two-plate mold does not occupy a separate runner plate but is more like a part of the mold cavity.

During injection molding, the runner, the sprue, and the finished product all cool and solidify simultaneously. When the mold is opened, they all come out at the same time. The final product is then separated from the sprue and the runner manually.

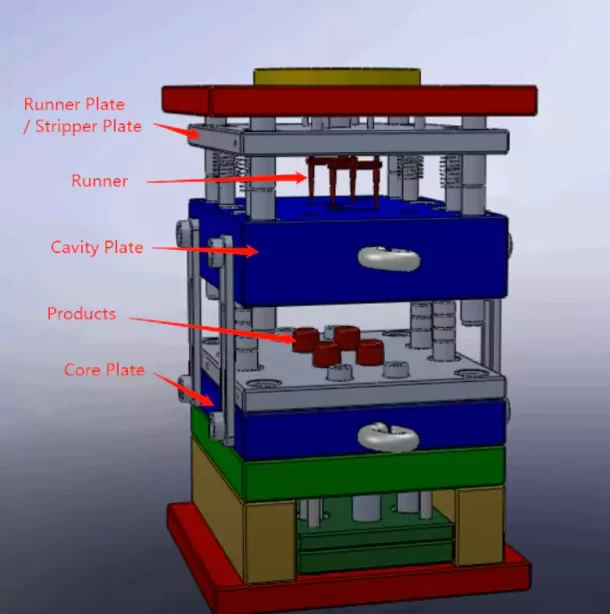

Three-plate mold

The structure of the three-plate injection mold is slightly complex. The runner is distributed on a cold runner plate separately. Although the runner and sprue are still cooling and solidifying with the final products at the same time, the runner and sprue will automatically separate from the part when the mold is opened.

Many products require uniform geometry. At this time, a three-plate mold has more advantages than a two-plate mold. For example, for injection molding circular products, two plate molds are easy to create the shape of an ellipse, and three plate molds can inject plastic at multiple points, so the material distribution and shrinkage are more uniform and the product’s roundness is better.

Cold Runner Systems’ Pros and cons:

Advantages of cold runner systems include a lower initial cost and simpler maintenance requirements. It is also more tolerant to heat-sensitive plastics. It is relatively easy to change the gate size or runner size to balance the plastic flow into the cavities. It is also easier for rapid color changes.

Cold runner system does not require highly trained and skilled mold designers and mold technicians. And the simplicity of the system is more tolerant to manufacturing faculties.

The disadvantages of cold runner systems include increased material waste and lower energy efficiency. Cold runner systems require a longer cooling time for a given part, therefore extending cycle time. Cold runner systems could also result in increased scrap rates as well as the potential for flashing or sink marks on the finished part. Cold runner systems are typically used for parts with lower production volumes or for materials that are sensitive to heat.

III. Hot Runner Systems

Hot-runner systems use heated runners to keep the material in a molten state until it is injected into the mold cavity. not like a cold runner system, whose runner and parts are cooled and ejected each cycle. In a hot runner mold, only the parts are called and ejected each cycle. There is no wasted plastic from the runner.

According to the method the runner system maintains the heat of the plastic in the runner, hot runner systems are divided into 3 categories. They are the insulated runner, the internally heated runner, and the externally heated runner.

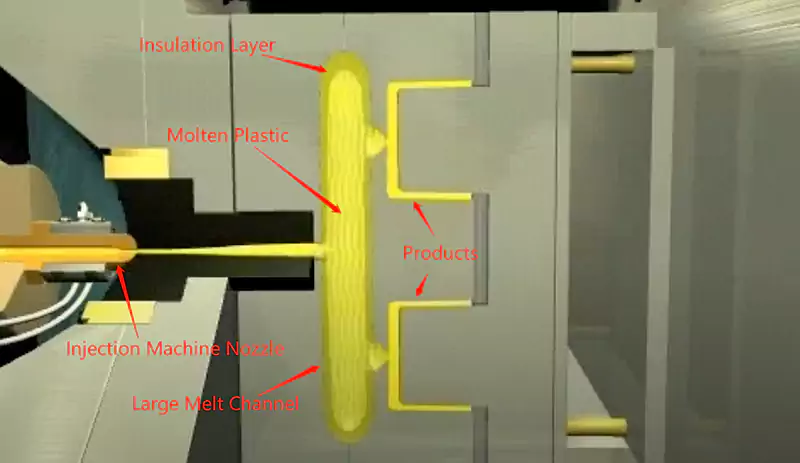

The insulated hot runner

The insulated hot runner appears the earliest among the 3 and also is the simplest. This basic hot runner design uses a very large channel to hold the molten plastic in the runner system. In that large channel, the plastic material close to the cold walls solidified first and formed an insulation layer, which kept the material in the center hot. The molten plastic flows through the center, providing enough heat to keep the runner flowing.

The insulated hot runner Short Comings

This design is very economical. It is suitable for fast-cycling molds. There is not much control in the runner system, so it is only suitable for general-purpose plastic material. When an insulated hot runner is solidified, either by a mechanical failure or just at the end of production, the runner plate has to be opened and the solidified runner has to be removed before production restarts.

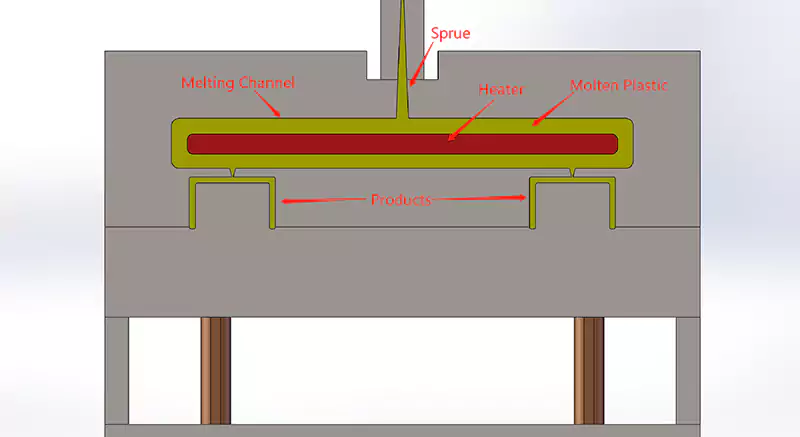

The internally heated runner

In this design, a heating device is used to provide heat to the plastic in the flow channel. The device is typically a tube or group of tubes with heating components inserted in the middle of the flow channels, heating the plastic material from the inside out. The plastic material close to the walls of the channels forms a cold layer, insulating the melted plastic from the metal walls. The system is still relatively simple and, hence, less costly to manufacture and maintain.

The internally heated runner Short Comings

The internally heated runner system is rather large. It needs to have a bigger melt channel to contain the heating tube. There are many intersections in the system, and the flow of plastic is not uniform, which causes the plastic to hang up and degrade. The plastic material close to the heater suffers from a much higher temperature than the plastic near the cold walls. And hence, this runner system is not suited to temperature-sensitive plastic materials.

If a color change is needed, the whole runner system has to be disassembled and the plastic in the system has to be cleaned before new color plastic can be injected. The process could be time-consuming and costly.

The externally heated runner

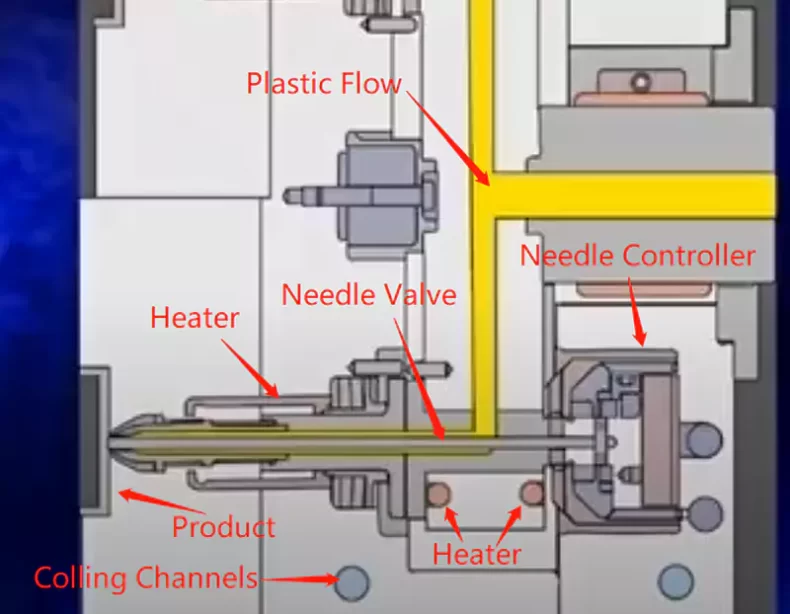

Despite its complexity, the externally heated runner is the most popular hot runner system among the 3. An externally heated runner system typically consists of the following main parts: the hot runner manifold, hot runner nozzles, and temperature control unit.

A hot runner manifold feeds molten material to the various nozzles that inject it into the mold cavity. External heaters are mounted in or on the manifold and nozzles. The heat transfer from manifold metal to plastic results in a more uniform temperature distribution in the plastic material.

Better Mold Flow

With this kind of heating, the melt channels are normally small and round, and material flow is unobstructed. In this system, there are no obstructions in the melt channels. This method offers the least resistance to the plastic flow and hence the lowest pressure drop. This may allow for a smaller injection machine in production. There is also less material hang-up because of the unobstructed channels, and therefore less chance of material degradation. Compared with the internal heating system, this system offers a much faster color or material change.

Longer Heater LifeTime

The temperature control unit is utilized to keep the molten material at a small temperature variation, ensuring that the material remains molten before being injected into the mold. The temperature control unit gives very precise control of the heater’s temperature. The heater in an external heating system works in a much better environment than the heaters in an internal heating system and therefore has a longer lifetime.

Better Control of the Injection Process

The valve gate, which controls the flow of material into the mold cavity, is another critical component of the hot runner system. The valve gate makes it possible to connect and disconnect the plastic distribution system from the mold cavity at any time. This gives a much better flow control in the plastic injection process.

Additional features like cooling channels and pressure sensors can be added to hot runner systems to increase the precision and control of the injection molding process.

Compared with the cold runner system and the other 2 rather simple hot runner systems, The externally heated runner system has more flexibility and control in injection molding. For example, gates can be opened and closed at different times to eliminate product defects such as impact marks, compound marks, etc.

This flexibility is essential to ensure the high-quality injection of large final parts. Since there is no solidified sprue or runner, the material is saved, as is the cycle time.

Short Comings

Hot runner systems require frequent maintenance and cleaning due to their complicated construction, which guarantees maximum performance and system life. This is especially important for external heating runner systems given their complexity.

The complexity of the external heating runner systems also means a longer mold-making time, higher mold cost, and requires more skilled technicians to assemble the mold, operate the injection process, and maintain the mold.

Hot Runner Systems’ Pros and cons

Advantages of hot runner systems include energy efficiency and reduced material waste. Hot runner systems can also result in faster cycle times and improved part quality, as well as lower scrap rates.

The disadvantages of a hot runner system include their higher initial cost and maintenance requirements. (A hot runner mold could cost 5 times as much as a cold runner mold or more.)

Hot runner systems are typically used for parts with very high production volumes and for materials that can withstand high temperatures for a longer time. Because, in the hot runner system, the plastic stays in the melting state longer.

IV. Factors to Consider When Choosing Between Cold Runner and Hot Runner Systems

Production volume and cost considerations:

The one-time investment in the hot runner system is relatively significant, but the production efficiency is high, and the production cost per cycle is low as the time to cool the runner is saved. In addition, the cost to regrind and recycle the runner is also saved.

On the contrary, the cold runner system’s injection cycle cost is higher, and the initial investment to obtain the best unit cost, the higher the expected total output of the product, the more the hot runner system should be considered, and the lower the total output, the more the cold runner system should be weighted. Typical hot runner system applications are mostly high-volume civilian products, such as bottle caps.

Material type and properties:

Although the hot runner system has been successfully applied to common plastics such as PA, PP, PET, POM, ABS, etc., it is still necessary to consider the residence time of plastics in the system when considering its use. If the time is too long, some heat-sensitive plastics will degrade, cause discoloration, and even change the properties of the materials.

Complexity and size of the part being molded:

The hot runner system gives more control over the final product’s quality. Products with large sizes have a greater chance of causing quality problems when injected, and the losses caused by waste products are also greater. Therefore, the hot runner system is usually a better choice for large or high-complexity products.

V. Conclusion

Cold runner and hot runner systems are the two main types of injection molding runner systems, each with its advantages and disadvantages.

Hot runner systems offer a shorter cycle time, a lower cycle cost, as well as a lower material cost, and a lower scrap rate for the final product. The trade-offs are higher initial and maintenance costs.

Cold runner systems are generally more cost-effective for lower production volumes and materials that are sensitive to heat, while hot runner systems may be more cost-effective for higher production volumes and materials that can withstand high temperatures for a longer time.

The production volume and cost considerations, material type and properties, and the complexity and size of the part being molded should be taken into account when deciding which type of system to use.

In the end, it is important to consult with a specialist to determine which system is best suited to your specific needs and requirements. If you have any questions about injection molding or mold manufacturing for your projects, send Capable Machining an email, and we will be glad to answer them.

FAQs:

- Can a hot runner system be used for low-volume production?

- Yes, a hot runner system can be used for low-volume production, but it may not be the most cost-effective solution in most of the low-quantity cases unless the target is to obtain good quality for large product injection.

- Can a cold runner system be used for high-volume production?

- Yes, a cold runner system can be used for high-volume production it is widely used for quantities like hundreds of thousands of pcs. The choice between a hot or cold runner system is a result of weighting material and cycle time lost against high mold cost and high maintenance cost.