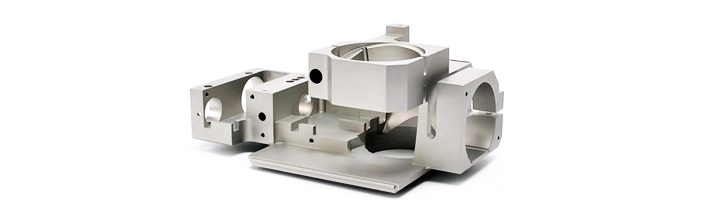

CNC Machining services

CNC Machining service

We provided best services to all customers.

Online CNC machining services for rapid prototypes and production parts. Get online CNC quotes today, and order your custom metal and plastic parts.

Start Quote

Promise: All files are secure and confidential.

CNC Milling

We use 3-axis, 4-axis, and 5-axis CNC milling to manufacture parts from more than 40 different plastics, metals, and rubbers. For small and massive volume production, first article inspection (FAI) is available upon request. Tolerance up to +/- 0.0004”(0.01mm). You can also get competitive prices for various additional heat treatments (aging, aneal, quenching, temper, and more), and surface treatments (anodizing, chromate plating, passivation, etc.).

3 Axis CNC Milling

Three-axis CNC is the most common type of CNC milling machine and is capable of handling most parts with great precision. Efficient and low cost. Learn More >

4 Axis CNC Milling

4-axis CNC can better handle parts that require multi-sided machining or curved surfaces. Machining costs are slightly higher than 3-axis machines, but flexibility is better. Learn More >

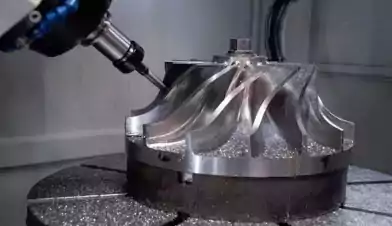

5 Axis CNC Milling

A 5-axis CNC can machine almost any complex shape. It is mostly used for curved surface parts with high requirements, or fine parts to be processed in multiple directions. The processing cost is high, and the maximum machinable size is smaller than the 4-axis and 3-axis CNC of the same level. Learn More >

Capabilities

Maximum Dimensions

2000mm x 1500mm x 800mm or 78.7 x 59 x 31.5 inches.

Tolerances

Dimension: Depends on the size and material, generally +/- 0.01mm or 0.0004 inches

Geometric: Depends on the size and material, generally +/- 0.01mm or 0.0004-inch

Support Threading

Prefer Metric Threads, Also Support UNC and UNF threads.

Wall Thickness

Depends on the Wall Depth Dimension and Material. Generally, a workable minimum wall thickness is 0.5mm for metals and 1.0mm for plastics.

Mini Bar Diameter

Depending on the depth of the hole, generally any hole with a diameter less than 0.8mm is problematic.

Material Available

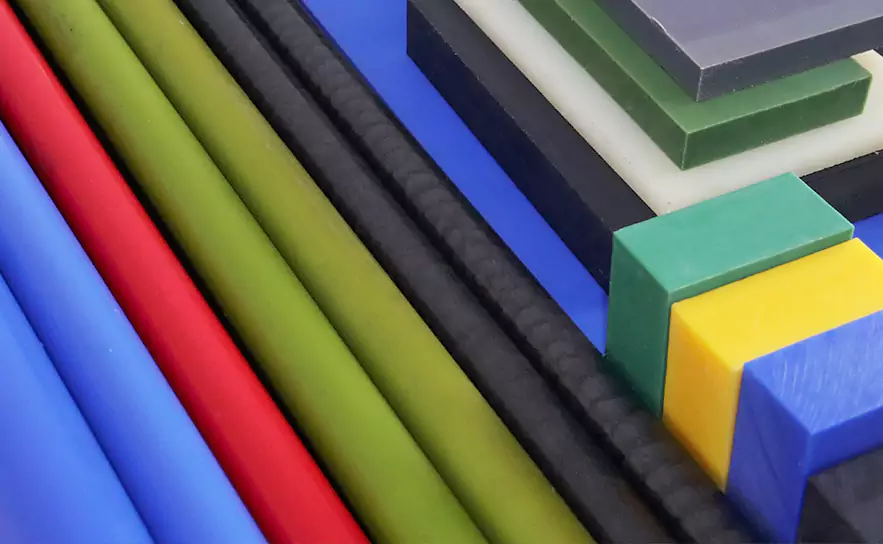

Plastic: ABS HDPE LDPE Nylon Peek PEI PPSU POM PS PSU PTFE PVC PC PMMA PP

Metals: Aluminum, Copper, Brass, Bronze, Stainless Steel, Carbon Steel, Steel Alloy, Titanium

Rest: Hard Rubber, Hard Polyurethane…

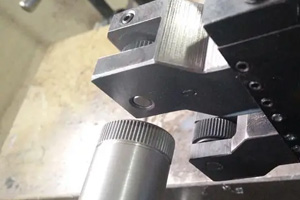

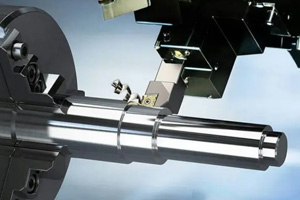

CNC Turning

CNC Turning and CNC Turn-Mill machining often provide better precision and speed for parts with primary cylindrical features. We use CNC lathes with multiple turning tools, ensuring fast and accurate manufacturing, particularly good at making parts primary to be a cylinder but with complicated features like flats, slots, and holes.

Boring

A single-point tool is fed in a linear manner, running parallel to the axis of rotation, within the inner diameter of a pre-existing hole.

Grooving

Grooving, as a type of CNC turning process, involves the formation of a narrow cavity by pressing a specially shaped tool into the workpiece.

Parting

Parting is a machining process that involves gouging to remove an entire piece from the original workpiece.

Threading

It is a specific type of CNC turning that facilitates the creation of grooves, enabling the workpiece to be easily screwed into other objects.

Knurling

This is a process where a workpiece is intricately cut into a serrated pattern, designed to enhance the grip of materials that require increased traction.

Taper Turning

Taper turning is a machining technique that involves shaping a cylindrical workpiece with a progressively decreasing diameter, resulting in a tapered shape.

Spherical Generation

By utilizing a programmed approach, a form is generated around a fixed axis to gradually decrease the diameter, eventually achieving a flawless spherical shape.

Cylindrical Turning

It is a machining process that uniformly reduces the diameter of the workpiece, ensuring consistent cutting diameter throughout to prevent any variations.

Capabilities

Maximum Dimensions

Maximum Diameter: 500mm or 19.7-inch

Maximum Length: 1800mm or 70.9-inch

Tolerances

Depending on the size and material, generally speaking

Metal: +/- 0.01mm (+/-0.0004 in)

Plastic: +/-0.025mm(+/-0.001 in)

Minimum Wall Thickness

Metal: 0.5mm or 0.02 in

Plastic: 1.0mm or 0.04 in

Material

Plastic: ABS HDPE LDPE Nylon Peek PEI PPSU POM PS PSU PTFE PVC PC PMMA PP

Metal: Aluminum, Copper, Brass, Bronze, Stainless Steel, Carbon Steel, Steel Alloy, Titanium… Learn More >

Common CNC DFM

Sharp Corner

Undercut

Thick Walls

Stress Deformation

Small Hole

Narrow Area

Tolerance Guide

Design for Manufacturing or Design for Manufacturability (DFM) is the optimisation of a part, product, or component’s design, to create it cheaper and more easily. DFM involves efficiently designing or engineering an object, generally during the product design stage, when it is easier and less expensive to do so, to reduce manufacturing costs. This allows a manufacturer to identify and prevent mistakes or discrepancies…Learn More >

Prototype, Bridge Production & Massive Production

Even if they are all processed by CNC machining, orders of different batches will still affect the processing technology. Compare as follows:

| Prototype | Bridge Production | Massive Production | |

|---|---|---|---|

| Prefered Machines | Smaller Tool Stock, More Axis | Bigger Tool Stock, More Axis | More Tool Stock, Less Axis |

| Fixtures | Mostly Standard Fixtures | Some Custom Made Fixtures | Custom Made Fixtures |

| Reachable Tolerance | High Precise with large Variance | Precise with some Variance | High Precise with small Variance |

| Price | Very High / Unit | High/Unit | Low/Unit |

| Other Things | Manual work might be needed like hand grinding, polishing, etc. | More Processes can be considered, forging, grinding, lasering, welding, brazing etc. |

Common CNC Metal Materials

We provide instant quotes for more than 100 kinds of metals and compare the prices of different processing materials for you.

Aluminum

Aluminum is widely favored for CNC machining, primarily due to its exceptional strength-to-weight ratio, corrosion resistance, and excellent machinability. This versatile material enables the creation of complex shapes and intricate parts, incorporating fine details with ease.

| Subtypes | Yield Strength | Elongation at Break | Hardness | Density | Max. service Temp |

|---|---|---|---|---|---|

| 6061-T6 | 35,000 psi | 12.50% | Brinell 95 | 2.768 g/㎤ 0.1 lbs / cu. in. | 130 – 150 °C |

| 7075-T6 | <68,000 psi | 11% | Brinell 126 | 2.768 g/㎤ 0.1 lbs / cu. in | 100 °C |

| 5052 | 23,000 psi | 8% | Brinell 60 | 2.768 g/㎤ 0.1 lbs / cu. in. | 190 °C |

| 6063 | 16,900 psi | 11% | Brinell 55 | 2.768 g/㎤ 0.1 lbs / cu. in. | 130 – 150 °C |

| 2024 | 43,500psi | 9~15% | Brinell 121 | 2.768 g/㎤ 0.1 lbs / cu. in. | 130 °C |

| 6083 | 42,000psi | 12% |

Stainless Steel

Stainless steel enjoys widespread popularity in CNC machining owing to its remarkable strength, durability, and resilience. Throughout the machining process, this material is expertly cut, shaped, and drilled using an array of cutting tools, including drills, mills, and lathes.

| Subtypes | Yield Strength | Elongation at Break | Hardness | Density | Max. Service Temp |

|---|---|---|---|---|---|

| 201 | 55,000 PSI | 52% | Rockwell B87 | 0.28 lbs / cu. in. | 450 – 843 °C |

| 301 | 33,000 PSI | 35 – 46 % | Rockwell B90 | 0.28 lbs / cu. in. | 450 – 870 °C |

| 303 | 35,000 PSI | 40-50 % | Rockwell C95 | 0.29 lbs / cu. in. | 750 – 925 °C |

| 304 | 31,200 PSI | 70% | Rockwell B70 | 0.29 lbs / cu. in. | 750 – 925 °C |

| 316 | 30,000 PSI | 38-55 % | Rockwell C95 | 0.29 lbs / cu. in. | 750 – 925 °C |

| 410 | 30,000 PSI | 20% | Rockwell B80 | 0.28 lbs / cu. in. | 190 – 860 °C |

| 416 | 44,000 PSI | 7-25% | Rockwell B80 | 0.28 lbs / cu. in. | 675 – 760 °C |

| 420 | 90,000PSI | 15 – 20 % | Rockwell C50 | 0.28 lbs / cu. in. | 650 – 700 °C |

| 430 | 30,000PSI | 20 – 24 % | Rockwell B89 | 0.28 lbs / cu. in. | 800 °C |

| 440C | 190,000 PSI | 8% | Rockwell C20 | 0.28 lbs / cu. in. | 420 – 810 °C |

| 630 | 160,000PSI | 10 – 15 % | Rockwell C40 | 0.28 lbs / cu. in. | 300 – 480 °C |

Carbon Steel

Carbon steel is a widely used material in CNC machining known for its high strength, hardness, and durability. It contains a higher carbon content, which enhances its machinability during CNC operations, resulting in precise and consistent parts. There are more materials not listed, please contact us for detailed.

| Subtypes | Yield Strength | Elongation at Break | Hardness | Density(lbs/cu.in.) |

|---|---|---|---|---|

| 1045 | 77,000 psi | 19% | Rockwell B90 | 7.87 g/㎤ 0.284 |

| 1018 | 60,000 PSI | 15% | Rockwell B90 | 7.87 g/㎤ 0.284 |

| 4130 | 122,000 psi | 13% | Rockwell C20 | 7.87 g/㎤ 0.284 |

| 4140 | 60,000 PSI | 21% | Rockwell C15 | 7.87 g/㎤ 0.284 |

| A514 | 100,000 psi | 18% | Rockwell C20 | 7.87 g/㎤ 0.284 |

| A340 | 122,000 psi | 13% | Rockwell C20 | 7.87 g/㎤ 0.284 |

Tool Steel

Tool steel finds widespread use in the production of molds for injection molding processes and as cutting tools, including drills, end mills, and lathe tools. Its ability to withstand high temperatures, mechanical stresses, and repeated cycles makes it an ideal choice for various industrial applications. There are more materials not listed, please contact us for needed.

| Subtypes | Yield Strength | Elongation at Break | Ultimate tensile strength | Thermal expansion coefficent | Maximum service temperature |

|---|---|---|---|---|---|

| D2 | 68,000 PSI | 16% | 124,000 PSI | 10.3 – 12 10^-6/ºC | 195 – 245 °C |

| A2 | 50,000 PSI | 21% | 103,000 PSI | 10.5 – 11 10^-6/ºC | 195 – 245 °C |

| O1 | 58,000 psi | 20% | 104,000 psi | 11.3 – 11.8 10^-6/ºC | 165 – 215 °C |

| A3 | 49,000 psi | 21% | 101,000 psi | 11.8 – 14.3 10^-6/ºC | |

| S7 | 55,000 psi | 25% | 97,000 psi | 10.7 – 11.2 10^-6/ºC | 165 – 215 °C |

| H13 | 47,000 psi | 21% | 100,000 psi | 10.4 – 12.4 10^-6/ºC |

Brass

Brass exhibits remarkable malleability and ductility, allowing for easy shaping and forming. Its bright, gold-like appearance makes it a favored choice for decorative and ornamental applications. Moreover, brass showcases excellent corrosion resistance and good electrical conductivity.

| Subtypes | Yield Strength | Elongation at Break | Hardness | Density |

|---|---|---|---|---|

| C360 | 15,000 PSI | 53% | Rockwell B78 | 0.307 lbs / cu. in. |

| CZ121 | 18,000 PSI | 17~20% | Rockwell B60 | 0.306 lbs / cu. in. |

| H70 | 42,000 PSI | 40% | Brinel 100 | 0.308 lbs / cu. in. |

| H68 | 53,000 PSI | 18~34% | Vickers 105 | 0.308 lbs / cu. in. |

| H65 | 56,000 PSI | 44% | 0.306 lbs / cu. in. |

Cooper

Brass, with its reddish-orange color, is a soft, malleable, and ductile metal. Renowned for its excellent electrical and high thermal conductivity, as well as good corrosion resistance, it remains a highly ductile and malleable material.

| Subtypes | Yield Strength | Elongation at Break | Hardness | Density |

|---|---|---|---|---|

| C110 | 42,000 psi | 9 – 30 % | Rockwell B50 | 0.322 lbs / cu. in. |

| C101 | 37,000 psi | 9 – 30 % | Rockwell B60 | 0.323 lbs / cu. in. |

| T1 | 42,000 psi | 45~50% | Brinel 35 | 0.3215 lbs / cu. in. |

| T2 | 28,000 psi | 45~50% | Brinel 35 | 0.3215 lbs / cu. in. |

| T3 | 30,000 psi | 45~50% | Brinel 35 | 0.323 lbs / cu. in. |

Titanium

Titanium is a valuable metal for CNC machining due to its silvery-white color and lightweight. It’s strong, durable, and resistant to corrosion, making it an excellent option. However, working with titanium in CNC machining requires expert skill and precision to meet specific requirements.

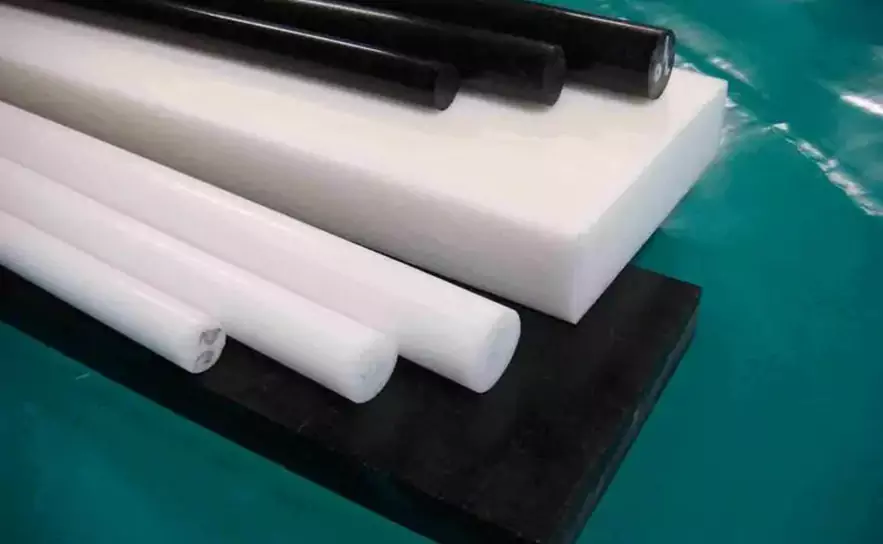

Common CNC Plastic Materials

We provide instant quotes for more than 200 kinds of plastic and compare the prices of different processing materials for you.

ABS

ABS is a copolymer made up of three monomers: acrylonitrile, butadiene, and styrene. The combination of these monomers provides ABS with a unique set of properties, including high impact resistance, good heat resistance, and excellent dimensional stability.

| Mechanical properties | |

|---|---|

| Ultimate tensile strength | 27.6 – 55.2 MPa |

| Yield strength | 18.5 – 51 MPa |

| Young’s modulus | 1.1 – 2.9 GPa |

| Elongation at break | 10 – 50 % |

| Hardness | 5.6 – 15.3 HV |

| Thermal properties | |

|---|---|

| Maximum service temperature | 61.9 – 76.9 °C |

| Thermal expansion coefficent | 84.6 – 234 10^-6/ºC |

| Thermal conductivity | 0.188 – 0.335 W/(m⋅°C) |

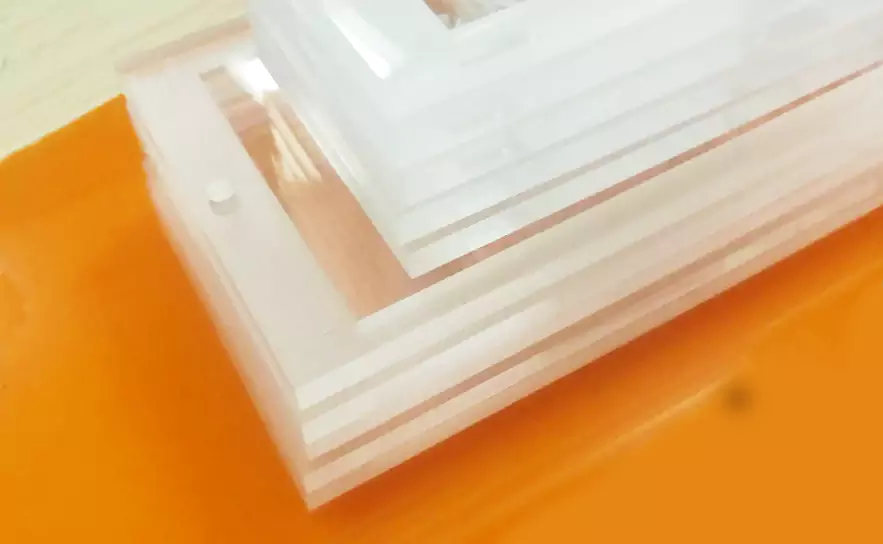

PMMA

PMMA also known as acrylic, is a tough and transparent material that resists UV radiation and weather. It can be easily colored, shaped, and used for various applications in construction due to its attractive appearance.

| Mechanical properties | |

|---|---|

| Ultimate tensile strength | 55 – 83 MPa |

| Yield strength | 64 -80 MPa |

| Young’s modulus | 2.76 – 3.3 GPa |

| Elongation at break | 3 – 6.4 % |

| Hardness | 64 – 105 HRM |

| Thermal properties | |

|---|---|

| Maximum service temperature | 70 – 80 °C |

| Thermal expansion coefficent | 50 – 90 10^-6/ºC |

| Thermal conductivity | 0.19 – 0.2 W/(m⋅°C) |

PE

PE (Polyethylene) is a popular thermoplastic polymer known for its exceptional properties. This lightweight, durable, and versatile material is widely used in various applications, as it can be easily processed into different shapes and sizes.

| Subtypes | Ultimate tensile strength | Yield strength | Young’s modulus | Elongation at break | Hardness |

|---|---|---|---|---|---|

| HDPE | 22.1 – 31 MPa | 26.2 – 31 MPa | 1.07 – 1.09 GPa | 500 – 700 % | 7.9 – 9.9 HV |

| UHMW-PE | 38.6 – 48.3 MPa | 21.4 – 27.6 MPa | 0.894 – 0.963 GPa | 200 – 500 % | 3.4 – 8.3 HV |

Nylon

Nylon, a synthetic thermoplastic polymer, requires careful consideration during machining to avoid overheating, which can lead to issues like melting, warping, or damage.

| Subtypes | Ultimate tensile strength | Yield strength | Young’s modulus | Elongation at break | Hardness |

|---|---|---|---|---|---|

| Nylon 6 | 64.7 – 79.1 MPa | 51.2 – 63.8 MPa | 1.58 – 1.97 GPa | 200-300 % | Shore D70 |

| Nylon 6 30% GF | 113 – 138.1 MPa | 111 – 137 MPa | 6.5 – 8.1 GPa | 2.81 – 4.05 % | Shore D92 |

| Nylon 66 30% GF | 90 MPa | 90 MPa | 5 GPa | 10 – 14 % | Shore D76 |

| Nylon 6 FR | 82 MPa | 82 MPa | 3.8 GPa | 3 % | Shore D83 |

| Nylon 12 | 80 MPa | 80 MPa | 1.9 GPa | 200% | Shore D78 |

| Nylon 66 | 76 MPa | 50 – 80 MPa | 1.85 GPa | 50% | Shore D82 |

PEEK

PEEK (Polyetheretherketone) is a unique engineering plastic known for its outstanding properties, including high-temperature resistance, self-lubrication, ease of processing, and exceptional mechanical strength.

| Mechanical properties | |

|---|---|

| Ultimate tensile strength | 70.3 – 103 MPa |

| Yield strength | 87 – 95 MPa |

| Young’s modulus | 3.76 – 3.95 GPa |

| Elongation at break | 30 – 150 % |

| Hardness | 26.1 – 28.5 HV |

| Thermal properties | |

|---|---|

| Maximum service temperature | 239 – 260 °C |

| Thermal expansion coefficent | 50 – 60 10^-6/ºC |

| Thermal conductivity | 0.24 – 0.26 W/(m⋅°C) |

PC

Polycarbonate is a strong and tough plastic with flame retardant and antioxidant properties. It has excellent impact strength, transparency, and mechanical properties.

| Mechanical properties | |

|---|---|

| Ultimate tensile strength | 60 – 72.4 MPa |

| Yield strength | 59- 70 MPa |

| Young’s modulus | 2 – 2.44 GPa |

| Elongation at break | 50 – 120 % |

| Hardness | 17.7 – 21.7 HV |

| Thermal properties | |

|---|---|

| Maximum service temperature | 101 – 144 °C |

| Thermal expansion coefficent | 120 – 137 10^-6/ºC |

| Thermal conductivity | 0.189 – 0.218 W/(m⋅°C) |

PP

PP (Polypropylene) boasts remarkable chemical resistance, a high melting point, and low density. When machining PP using CNC, it’s crucial to use a sharp cutter with a high front angle and a low cutting speed. These measures prevent the material from overheating and melting.

| Subtypes | Ultimate tensile strength | Yield strength | Young’s modulus | Elongation at break | Hardness |

|---|---|---|---|---|---|

| PP Homopolymer | 19 – 30 MPa | 0.7 – 1.2 GPa | min. 50 % | ||

| PP | 23 – 33 MPa | 30 – 32 MPa | 0.9 – 1.6 GPa | 8 – 12 % | 65 – 102 HRR |

| PP+GF(30%) | 68 – 85 MPa | 6.5 – 7 GPa | 2.1 – 3.4 % | 110 HRC |

PET

Polyethylene terephthalate (PET), a thermoplastic material, is a viable option for CNC milling and lathing processes due to its good machinability and versatility. With proper tooling and cutting parameters, PET can be easily shaped and formed, making it ideal for creating prototypes, custom parts, and containers through CNC machining.

| Mechanical properties | |

|---|---|

| Ultimate tensile strength | 50 – 90 MPa |

| Yield strength | 47 – 90 MPa |

| Young’s modulus | 2 – 3 GPa |

| Elongation at break | 20 – 300 % |

| Hardness | 80 – 96 HRM |

| Thermal properties | |

|---|---|

| Maximum service temperature | 60 – 115 °C |

| Thermal expansion coefficent | 40 – 60 10^-6/ºC |

| Thermal conductivity | 0.15 – 0.28 W/(m⋅°C) |

PEI

PEI (Polyetherimide) is a tough and durable material known for its high melting point and abrasive characteristics. By utilizing specialized cutting tools and techniques, it can be effectively cut and shaped to produce high-quality parts with precise tolerances.

| Subtypes | Ultimate tensile strength | Yield strength | Young’s modulus | Elongation at break | Maximum service temperature |

|---|---|---|---|---|---|

| PEI Ultem 1000 | 125 MPa | 125 MPa | 3.1 – 3.3 GPa | 12 – 35 % | 170 °C |

| PEI Ultem 2300 30% Glass Filled | 135 MPa | 135 MPa | 5.3 GPa | 4 % | 170 °C |

POM

POM (Polyoxymethylene) is a thermoplastic material renowned for its high stiffness, low friction, easy cutting, and excellent dimensional stability. However, machining POM can be challenging due to its high melting point and susceptibility to chipping or cracking if the cutting parameters are not carefully controlled.

| Subtypes | Ultimate tensile strength | Yield strength | Young’s modulus | Elongation at break |

|---|---|---|---|---|

| Acetal Copolymer(POM-C) | 60 – 70 MPa | 60 – 67 MPa | 2.5 – 2.7 GPa | 30 – 32 % |

| Acetal Copolymer (POM-C) FDA | 70 MPa | 66 – 70 MPa | 2.8 – 3 GPa | 32 – 40 % |

| Acetal Homopolymer (POM-H) | 60 – 89.6 MPa | 48.6 – 72.4 MPa | 2.5 – 4 GPa | 15 – 75 % |

| Acetal Copolymer (POM-C) ESD | 39 MPa | 45 MPa | 2.5 – 2.7 GPa | 40 – 50 % |

PVC

PVC is strong, durable, and resistant to chemicals, weather, and fire. However, machining it can create harmful dust and fumes that may be unsafe for workers. To keep workers safe, use proper safety equipment and ventilation during the process.

| Mechanical properties | |

|---|---|

| Ultimate tensile strength | 46 – 58 MPa |

| Yield strength | 53 – 58 MPa |

| Young’s modulus | 2.18 – 3.41 GPa |

| Elongation at break | 25 – 80 % |

| Hardness | 13.7 – 16.6 HV |

| Thermal properties | |

|---|---|

| Maximum service temperature | 85 – 100 °C |

| Thermal expansion coefficent | 112 – 149 10^-6/ºC |

| Thermal conductivity | 0.133 – 0.144 W/(m⋅°C) |

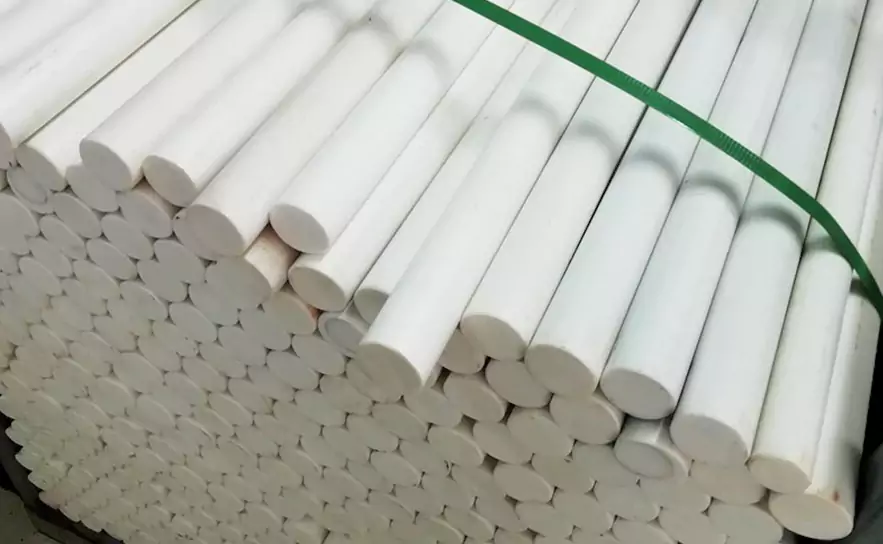

PTFE

When machining PTFE, using the right cutting tools is crucial because PTFE has a low friction coefficient, which can lead to overheating and deformation of the tool. To overcome this, carbide cutting tools are commonly employed as they are durable and can withstand heat effectively.

| Mechanical properties | |

|---|---|

| Ultimate tensile strength | 25 – 31 MPa |

| Yield strength | 14 – 41.4 MPa |

| Young’s modulus | 0.39 – 2.25 GPa |

| Elongation at break | 300 – 450 % |

| Hardness | 50 – 65 Shore D |

| Thermal properties | |

|---|---|

| Maximum service temperature | 250 – 270 °C |

| Thermal expansion coefficent | 7 – 20 10^-6/ºC |

| Thermal conductivity | 0.23 – 0.5 W/(m⋅°C) |

Surface Finishes

We have experienced professionals for surface treatment of products

| Name | Description | Materials | Color | Texture | More |

|---|---|---|---|---|---|

| Brushing | Brushing is a surface treatment technique that creates decorative lines on the workpiece by grinding the product, resulting in a beautiful and aesthetically appealing finish. | Aluminum, Brass, Stainless Steel, Steel, ABS,etc | N/A | Satin | |

| Sand Blast | Sandblasting is a method that uses high-speed sand flow to clean and roughen the surface of a product. It serves to achieve a specific level of cleanliness and varying roughness on the workpiece surface. | All Metal Materials, Plastic | N/A | Matte | |

| Tumbling | Tumbling is a surface treatment process where materials are placed in a rotating drum or container with abrasive media. The action of tumbling smoothens surfaces, deburrs edges, and improves uniformity. | All Materials | N/A | Smooth, Matte | |

| Polishing | Polishing is a mechanical surface treatment process that uses abrasives or buffing wheels to remove imperfections, smooth surfaces, and enhance the appearance of materials, leaving a shiny and reflective finish. | All Materials | N/A | Smooth | |

| Anodizing | Anodizing is a surface treatment for aluminum and its alloys. It forms a protective layer that boosts corrosion resistance, wear resistance, and hardness while changing the material’s surface appearance. | Aluminum, Titanium | Clear, Yellow, Green, Blue, Black, etc |

Smooth, matte finish. | |

| Painting | Attach the product to be sprayed onto the rotating bracket, and then secure the bracket on the assembly line. Apply the paint evenly to the product’s surface. This process enhances the product’s tactile feel, but it may be susceptible to scratches. | All Materials | Clear, Yellow, Green, Blue, Black, Multiple | Gloss, semi-gloss, flat, metallic, textured | |

| Black Oxide | Black oxide is an oxide film primarily utilized to enhance product corrosion resistance and appearance, while reducing light reflection. It is well-suited for treating steel and stainless steel surfaces. | Steel, Stainless Steel | Black | Smooth, matte | |

| Electroplating | Electroplating serves functional, decorative, and corrosion-related purposes, finding widespread use across various industries. For instance, the automotive sector often employs chrome-plating on steel automobile parts. | Aluminum, Steel, Stainless Steel | Gold, Silver, Nickel, Copper, Brass, Zinc, Chrome | Smooth, glossy finish | |

| Powder Coating | Powder coating is a technique for applying dry powder to metal surfaces, typically done electrostatically. The coated metal is then cured through heating or ultraviolet light to create a durable and attractive finish. | Aluminum, Stainless Steel, Steel,etc | Custom | Gloss, matte or semi-gloss | |

| Alodine | An alodine finish is a conversion coating applied to aluminum parts, creating a thin protective film that helps prevent corrosion. It also serves as a primer for further painting processes. | Aluminum, Stainess Steel | Clear, Gold | As machined | |

| Passivation | Passivation used on stainless steel to enhance corrosion resistance. It involves immersing the metal in an acid solution, removing contaminants, and forming a protective oxide layer on the surface, preventing rust and corrosion. | Stainess Steel | N/A | Matte | |

| Electroless Plating | Electroless plating is a chemical process depositing metal onto a substrate without an external electrical current. It involves a catalytic reaction between the substrate and a metal ion solution, creating a uniform and adherent coating. | Metal, Plastic | Gold, Silver, Nickel, Copper, Brass, Zinc, Chrome | Smooth, glossy finish |

Frequently Asked Questions

Currently, we don’t provide design services, just focus on CNC machining. Although we do have engineers capable of making CAD designs, designing involves intensive knowledge in the field of the product required. Our specialty is converting a design to real not converting an idea to a design.

Yes, we are happy to help you with our knowledge of materials. Please send us the information, we will arrange for engineers to sort it out.

Yes, we do. We manufacture gear, worm, helical gear and some bevel gear in our CNC machining service.

No, we don’t manufacture wood product.

We don’t do 3D print ourself, if you need them, we can outsources for you.

Yes, we do. We do part marking with silk screening, laser engraving, and etching. If you need such service, please send design of the marking in .ai or .dwg form.

Yes we can. 2D drawing contains important information like tolerances, heat treatment, surface treatment etc. Without we will following ISO2768 medium for metal parts and ISO2768 coarse for plastic parts as default, and no heat treatment, no surface treetment, unless otherwise claimed.

The answer is case by case. It depends on if we have the assembly equipments and environment. If it is a simple assembly and we have the equipments, we will offer assembly service.

Stp file is an standard 3D file that all CAD and CAM programes (Proe, UG, Solidworks etc.) can open and convert to. If you only have CAD files with other file extension, send to us, we can covert it to stp file.

Related Blog

Research Review and Development Trend of Deep hole Machining Technology

Deep hole machining technology was firstly applied in the field of military production, mainly used …

Research on CNC milling process of thin-walled parts

Provide CNC Machining service with rich experiecnces.CNC machining technology as an important compon…

Application of milling technology in CNC turning and milling center

The CNC turning and milling compound center is a multifunctional machine tool that can realize milli…