High pressure Die casting in Utah

High pressure Die casting for Utah

Welcome to our Die Casting Service, where precision meets efficiency, crafting quality components for your industry needs.

Custom Parts, On Demand Manufacturing

We Provide Satisfactory High pressure Die casting services in Utah

Provide you with high-quality and cost-effective cast parts.

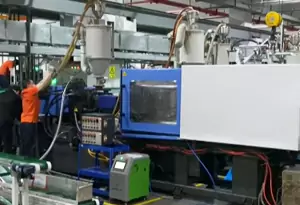

Welcome to CapableMachining, your premier provider of die casting services. With years of expertise and state-of-the-art technology, we offer high-quality, precision die casting solutions for a wide range of industries. Our dedicated team is committed to delivering exceptional results and exceeding customer expectations. Trust CapableMachining for all your die casting needs. Contact us today to learn more about our services.

Type services

We offer versatile die-casting services tailored to your product specifications, utilizing both hot chamber and cold chamber systems. Hot chamber systems cater to alloys like zinc, tin, and lead with lower melting points, while cold chamber die-casting machines excel with high melting temperature alloys such as aluminum, brass, and magnesium. Ensuring top-tier manufacturing solutions for your diverse needs.

Hot chamber system

Hot chamber die-casting machines are used for alloys with lower melting points. The molten metal flows into the injection chamber through the inlet, and the hydraulically driven plunger forces the molten metal through the gooseneck channel and into the mold.

Cold chamber system

Cold chamber die-casting machines are used for alloys with high melting temperatures. The molten metal is still kept in an open insulated tank. These alloys cannot be cast in hot chamber die-casting machines because they will damage the pumping system.

Relative services

Capabilities

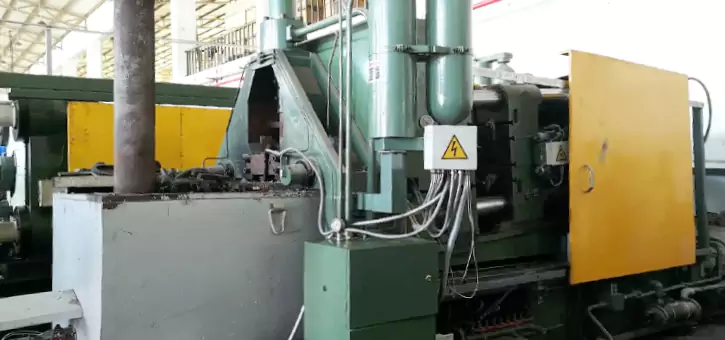

Equipment

Hot chamber system: clamp force up to 400 tons

Cold chamber system: clamp force up to 800 tons

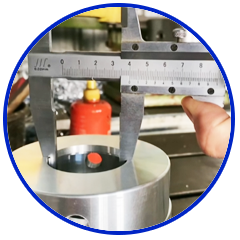

Tolerances

Product: Heavily depending on the part type and the size of the part, typically +/- 0.1mm or +/-0.04 inch

Tooling tolerance: typically +/- 0.01mm or +/-0.004inch

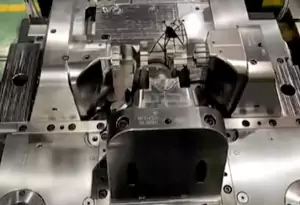

Mold Life Cycle

Typically 30,000~50,000

Leading Time

Tooling: 35 days

Casting: 5~7 days

Material

Aluminum Alloy: ADC7,ADC10, ADC12,ADC14 A380, A360, A353

Zinc Alloy: ZA,ZA12, ZA27, AG-40, AG-41

Magnesium Alloy: AZ91D, AZ80M, AZ31B, AM60B, M2M

Thin wall

Typical: >1.5mm(depend on parts type and size)

Common Materials

Die casting materials are divided into the following three categories according to the properties of the metal materials used

Aluminum alloys

Die-casting aluminum alloys have good performance and process performance, so the die-casting of aluminum alloys has developed rapidly and has been widely used in various industrial sectors.

Material properties:

- Strong and durable: Aluminum alloys are tough, hard, and resist corrosion. For instance, parts made from ADC12 are both sturdy and wear-resistant.

- Efficient heat transfer: Aluminum alloys boast exceptional thermal conductivity. This efficiently spreads and dissipates heat, enhancing parts’ ability to withstand high temperatures. This is particularly crucial in applications like car engines, electric fans, and LED lights, where efficient heat dissipation is essential.

- Easy to mold: Aluminum alloys are highly fluid, allowing them to effortlessly fill molds and solidify rapidly to create desired parts. This ease of molding enables efficient mass production of numerous identical or diverse parts within a short timeframe.

common types: ADC7,ADC10, ADC12,ADC14 A380, A360, A353

Magnesium alloys

Magnesium alloy is an alloy composed of magnesium and other elements. The main alloying elements are aluminum, zinc, manganese, cerium, thorium and a small amount of zirconium or cadmium.

Material properties:

- Light weight, high specific stiffness, high specific strength, strong thermal conductivity

- Good machining performance, good impact resistance and compression resistance

- Good die-casting performance, good dimensional accuracy and stability

- Good regeneration, can be completely recycled

- Low corrosion resistance, flammable and explosive

Mainly used in aerospace, military, automobile, motorcycle and 3C electronic products.

Type: AZ91D, AZ80M, AZ31B, AM60B, M2M

Zinc alloys

Zinc alloy is an alloy composed of zinc and other elements. Often added alloying elements are aluminum, copper, magnesium, cadmium, lead, titanium and other low-temperature zinc alloys.

Material properties:

- Large specific weight; good casting performance, can die-cast precision parts with complex shapes and thin walls, and the surface of the castings is smooth;

- Surface treatment can be carried out: electroplating, spraying, painting, electrophoresis, polishing, water transfer printing, etc.;

- It has good mechanical properties and wear resistance at room temperature;

- Poor corrosion resistance, not suitable for use in high temperature and low temperature (below 0°C) working environment

Mainly used in toys, lamps, decorations, auto parts, mechanical and electrical parts, electrical components and their casings.

Type: AZ91D, AZ80M, AZ31B, AM60B, M2M, etc.

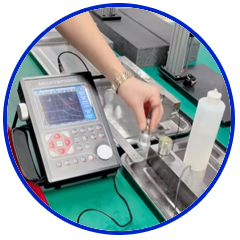

Our Quality Control

Our company boasts a recognized quality assurance framework and a team of competent technical engineers who diligently oversee every aspect of our product manufacturing process – from obtaining top-notch raw resources to delivering impeccable finished goods that encompass metals and plastics. To uphold our devotion to excellence, we extensively utilize cutting-edge testing technology and cutting-edge equipment to meticulously evaluate crucial parameters such as workpiece dimensions, hardness, tensile strength, and elongation at every stage of production. We wish to maintain utmost control over these data points to meet and surpass the expectations of our esteemed clientele consistently.

Professional quality control Engineer

Tolerances up to ±0.0004″ (0.01mm)

State-of-the-art Inspection Facilities

Proven and reliable quality control system.

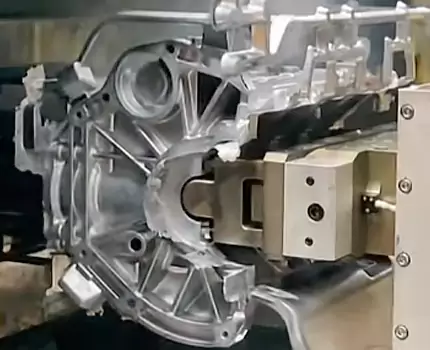

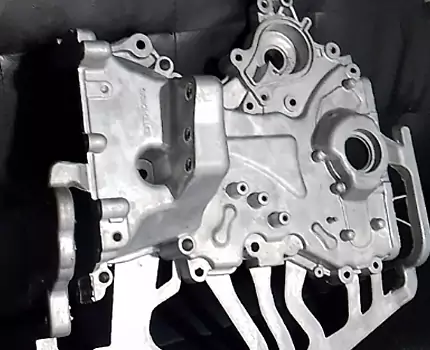

Gallery of Parts

Auto Parts

Material: AL

Equipment part

Material: AL

Comsumer part

Material: AL

New energy auto

Material: AL

Industry parts

Material: AL

Agriculture machine parts

Material: AL

Other capabilities

- Free & Automatic DFM feedback

- Tolerances: typically +/- 0.15mm or +/-0.006 inch

- Tooling: 30 days

- Free advices from high trained engineers.

- Quotation in a few hours.leading time 3 days

- Fast delivery time

- Tolerances: typically +/- 0.15mm or +/-0.006 inch

- Free consultant ,Free DFM feedback

- Typically Tooling: 30 days

- Wide range of material choices

- Free consultant from engineers

- Fastest leading time: 1 day

- Free & Automatic DFM feedback

- Tolerances up to ±0.00078″ (0.02mm)

- Rapid tooling: 7~12 days

How do find our location?

High pressure Die casting in Utah

Other Location Near me

FAQ

High Pressure Die Casting Q&A

Welcome to our Q&A session where we will be discussing important aspects of high pressure die casting in Utah. Below are 10 pairs of commonly asked questions and their corresponding answers to help you better understand this manufacturing process.

Q: What is high pressure die casting?

A: High pressure die casting is a manufacturing process in which molten metal is injected into a steel mold cavity under high pressure to produce complex metal parts with high accuracy and consistency.

Q: What materials can be used in high pressure die casting?

A: A variety of materials can be used in high pressure die casting, including aluminum, zinc, and magnesium alloys.

Q: What are the advantages of high pressure die casting?

A: Some advantages of high pressure die casting include high productivity, net-shaped parts, excellent surface finish, and the ability to produce complex geometries.

Q: Is high pressure die casting cost-effective?

A: High pressure die casting can be cost-effective for large production runs due to its high productivity and minimal need for secondary operations.

Q: What industries use high pressure die casting?

A: Industries such as automotive, aerospace, electronics, and industrial equipment commonly use high pressure die casting for the production of metal parts.

Q: How can high pressure die casting benefit companies in Utah?

A: High pressure die casting can benefit companies in Utah by providing them with high-quality metal parts at competitive prices, leading to improved efficiency and profitability.

Q: What quality control measures are used in high pressure die casting?

A: Quality control measures in high pressure die casting include process monitoring, dimensional inspections, and material testing to ensure that parts meet specifications.

Q: How can companies in Utah find a reliable high pressure die casting partner?

A: Companies in Utah can find a reliable high pressure die casting partner by conducting research, asking for recommendations, and evaluating potential suppliers based on their capabilities and track record.

Q: What is the future outlook for high pressure die casting in Utah?

A: The future outlook for high pressure die casting in Utah is positive, with advancements in technology and materials driving innovation and growth in the industry.

Conclusion

We hope this Q&A session has provided you with valuable insights into high pressure die casting in Utah. By understanding the fundamentals of this manufacturing process, companies can make informed decisions and leverage the benefits of high pressure die casting for their production needs.