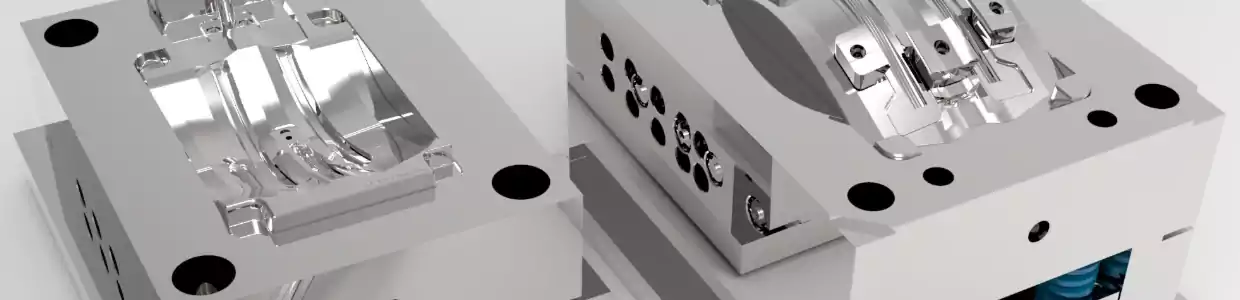

Rapid Mold

Need a mold with 1/3 of the normal leading time, half of the cost? That is what we call Rapid Mold.

If you have a plastic product design, you like to release it to the market as soon as possible, but you don’t know how the market is going to react, and there is a chance the design will be amended later. 3D printing does not deliver the right precision, material, or outlook. You need a mold that is quick and cheap but does not expect a significant product quantity. That is where rapid mold fits in.

Capabilities

Tolerances

Heavily depending on the plastic type and the size of the part, typically +/- 0.15mm or +/-0.006 inch

Materials

Most of the thermal plastic, ABS, HDPE, PE, PC, PMMA, PA6, PA66, POM, PBT, PET, PVC TPU, TPE, Silicone Rubber… Learn More >

Tooling Leading Time

Typically 7~12 days.

Mold Life Cycle

Typically 10,000~30,000

Mold Core

Carbon Steel or Mold Steel

General Workflow of Tooling

Injection mold, rapid mold and casting mold

1

material color

mold life cycle

mold surface

first lot quantity tolerance

2

3

4

partial line, push pin, slider, shrinkage mark position, cavity and core.

5

Making mold upon Customer’s feedback on DFM

6

T0 (first test of mold) & Adjusting mold

7

T1 (second test of mold) and provide product samples to customer.

8

Production after Customer confirm samples

Frequently Asked Questions

You own the mold. You can export the mold anywhere you like to. But different country has different regulation of importing molds. Also Molds are heavy, transport could be costly. If you plan to export the molds you ordered, please let us know before ordering.

We keep your mold in our facility for at least 3 years. After 3 years, if no further production are done, we will send you a email of how to deal with the molds.

Yes, we manufacture molds for rubber making, plastic blowing processes too.

We don’t suggest apply anodizing to casting Aluminum. The high Si content of casting Aluminium cause problems in anodizing. The oxide layer peels off and there will be spots. Suggest using paint or plating to casting Aluminium products.

Please send any thing related to the website to support@capablemachining.com. We will make sure the resolution asap. Any input or suggestions are welcome.

Please send the following information:

#A screen shot.

#The exact URL

#Your browser and operation system

#Any other files that help understand the problem.