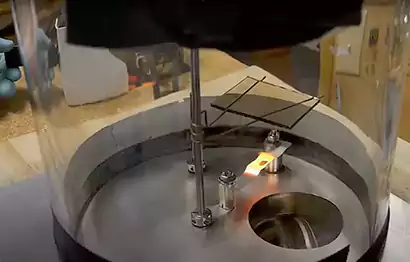

Advancing Surface Engineering: Vacuum Coating

Table of Contents What is a vacuum coating? Basic Principles Vacuum Environment Evaporation Sputtering Ion Plating Chemical Vapor Deposition (CVD) Types of Vacuum Coating Technology Physical Vapor Deposition (PVD) Coatings Chemical Vapor Deposition (CVD) Coatings Magnetron Sputtering Atomic Layer Deposition…