Advancing Surface Engineering: Vacuum Coating

Boiling water in high mountains does not need 100 degrees Celsius. This is because the boiling point of a substance decreases at low pressure. Therefore, if a sub-atmospheric pressure environment can be provided, many substances that do not volatilize under normal pressure will volatilize easily. Vacuum coating is a process that uses this phenomenon to volatilize the coating material and deposit it on the substrate to form a coating by means of heating or ion sputtering under low pressure.

Vacuum coatings find extensive application in safeguarding a wide range of items, spanning from medical instruments to aerospace components. These coatings offer exceptional resistance against wear, friction, corrosive chemicals, and high temperatures, thereby significantly enhancing the longevity of the protected objects. Notably, thin-film deposition coatings achieved through vacuum processes offer distinct advantages over alternative protective coating methods. Unlike other techniques, vacuum coatings eliminate the potential for unwanted side effects. Conventional coating methods may inadvertently disrupt the precision of a tool or add excessive thickness, thereby impairing its intended performance.

What is a vacuum coating?

Vacuum coating, or thin-film deposition, involves the application of a remarkably thin and uniform layer of coating onto a substrate’s surface through a vacuum chamber process. This technique serves to shield the substrate from external factors that could lead to wear and reduce its overall efficiency. Vacuum coatings are characterized by their thinness, typically ranging from 0.25 to 10 microns (0.01 to 0.4 thousandths of an inch) in thickness.

Basic Principles

The basic principles of vacuum coating involve creating a controlled environment with low pressure and utilizing various processes to deposit thin films or coatings onto substrates. Here are the fundamental principles:

Vacuum Environment

Vacuum coating requires a controlled low-pressure environment to minimize unwanted interactions between the coating material and the surrounding gases. By reducing the gas molecules’ density, the probability of collisions and reactions is minimized, allowing for precise control of the vacuum coating process.

Evaporation

Evaporation is a common technique used in vacuum coating. It involves heating the coating material until it reaches its vaporization point, transitioning it from a solid to a vapor phase. The vaporized material then condenses onto the substrate, forming a thin film. The evaporation can be achieved through thermal heating or electron beam bombardment.

Sputtering

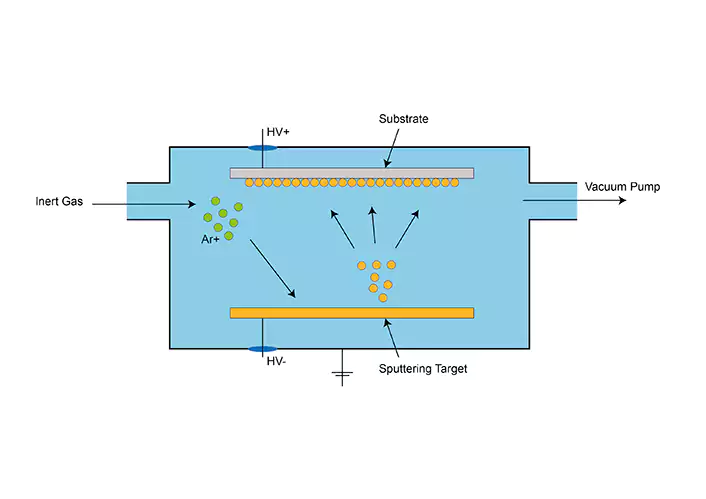

A sputtering deposition is a physical vapor deposition (PVD). It involves bombarding a target material with high-energy ions (usually from a plasma) that dislodge atoms from the target surface. These dislodged atoms then deposit onto the substrate, forming a coating. Sputtering enables precise control over the coating composition, and it is commonly used for metallic and compound coatings. It is particularly useful for those materials that have a very high melting point (e.g.tungsten) or could break down at high temperatures (e.g. Nickel oxide).

Ion Plating

Ion plating is a technique that combines evaporation and ion bombardment to enhance coating adhesion and density. During ion plating, the coating material is evaporated, and simultaneous ion bombardment of the substrate occurs. The ions assist in cleaning the substrate surface and promote denser and more adherent coating growth.

Chemical Vapor Deposition (CVD)

CVD is a process where precursor gases react chemically on the substrate surface to form a solid coating. In vacuum coating, low-pressure CVD and plasma-enhanced CVD are commonly used. Low-pressure CVD involves the thermal decomposition or reaction of precursor gases, while plasma-enhanced CVD utilizes plasma to enhance the chemical reactions and deposition rates.

Types of Vacuum Coating Technology

There are several types and uses of Vacuum Coatings. The following is a quick overview to get you familiar with the technologies used.

Physical Vapor Deposition (PVD) Coatings

a. Thermal Evaporation: In this process, materials are heated until they reach their vaporization point, and the resulting vapor condenses on the substrate to form a coating.

b. Electron Beam Evaporation: Similar to thermal evaporation, vaporization is achieved using an electron beam to heat the material source. This technique is widely used for depositing metals and other materials that have high melting points.

c. Sputtering: It involves the bombardment of a target material with high-energy ions, causing atoms to be ejected and deposited onto the substrate.

d. Ion Plating: In ion plating, a high-energy ion beam is directed toward the target material in a vacuum chamber. The ions bombard the target, causing atoms to be ejected and deposited onto the substrate surface. Unlike traditional sputtering, ion plating incorporates the use of a concurrent or sequential ion beam to assist in the film deposition process.

Chemical Vapor Deposition (CVD) Coatings

a. Plasma-Enhanced CVD: It is a vacuum technology that uses plasma to generate reactive species that react with precursor gases, resulting in the deposition of a solid coating on the substrate.

b. Low-Pressure CVD: Coating deposition occurs in a low-pressure environment, utilizing thermal decomposition or reaction of precursor gases.

c. Atmospheric Pressure CVD: The coating is deposited at atmospheric pressure, allowing for faster and more cost-effective processing.

Magnetron Sputtering

It is a variation of sputtering where a magnetic field is applied to enhance the efficiency and control of the sputtering process.

Atomic Layer Deposition (ALD)

In ALD, the substrate is placed inside a vacuum chamber, and a cycle of deposition is performed. During each cycle, the substrate is exposed to a specific precursor gas, forming a self-limiting monolayer on the surface. The precursor gas reacts with the surface, creating a thin layer of material. Excess precursor and reaction by-products are then removed before the next cycle begins. This controlled layer-by-layer deposition process allows for precise control over the film thickness, composition, and uniformity.

ALD offers several advantages, including excellent conformality, precise thickness control at the atomic level, and the ability to deposit a wide range of materials, including metals, oxides, nitrides, and more. It is particularly suitable for depositing thin films on complex and high-aspect-ratio structures, such as semiconductor devices, microelectronics, catalytic materials, and energy storage systems.

Materials Used in Vacuum Coating

Materials used in vacuum coating can vary depending on the specific application and types of vacuum coating machine. Here are some commonly used materials:

Metals

Various metals are frequently employed in vacuum coating due to their desirable properties, such as high conductivity, reflectivity, and corrosion resistance. Examples include aluminum, titanium, copper, silver, gold, and chromium.

Alloys

Alloy compositions are utilized to achieve specific properties or enhance the performance of the coating. For instance, titanium nitride (TiN) is a popular hard coating used for wear resistance, while nickel-chromium (NiCr) alloys are used for corrosion protection.

Ceramics

Ceramic materials are employed in vacuum coating to provide high-temperature resistance, electrical insulation, and wear resistance. Examples include titanium dioxide (TiO2), aluminum oxide (Al2O3), and silicon nitride (Si3N4).

Polymers

Certain polymers can be used in vacuum coating to provide functional properties such as lubricity, anti-adhesion, or anti-reflectivity. Examples include polytetrafluoroethylene (PTFE) and polyethylene terephthalate (PET).

Thin Films of the silicon compound

Vacuum coating can also involve the deposition of thin films of materials such as silicon dioxide (SiO2) or silicon nitride (Si3N4). These films can provide optical properties, and barrier properties, or serve as insulating layers.

Nanomaterials

Nanoscale materials, including nanoparticles and nanocomposites, are gaining popularity in vacuum coating applications due to their unique properties. Nanomaterials can be used to enhance coating hardness, improve scratch resistance, or achieve specific optical effects.

Applications of Vacuum Coating

Vacuum coating finds a wide range of applications across various industries due to its ability to enhance the performance, durability, and aesthetic appeal of materials and surfaces. Here are some common applications of vacuum coating:

Optics and Optical Coatings

Vacuum coatings are extensively used in the optics industry to create anti-reflective coatings, mirror coatings, and filters for lenses, eyeglasses, telescopes, microscopes, and camera lenses. These coatings improve light transmission, minimize reflection, and enhance optical clarity.

Electronics and Semiconductor Industry

Vacuum coatings play a vital role in electronics manufacturing. They are used to create conductive coatings for electrical contacts, printed circuit boards (PCBs), and connectors. Thin films deposited through vacuum coating are also utilized for insulation, passivation, and corrosion protection of electronic components.

Automotive Industry

Vacuum coatings are applied in the automotive sector to enhance the durability and appearance of various components. Examples include decorative coatings for interior trim, anti-corrosion coatings for engine components, wear-resistant coatings for pistons and cylinders, and anti-reflective coatings for headlights and mirrors.

Solar Panels and Energy Systems

Vacuum coatings are employed in solar panel manufacturing to create anti-reflective coatings on glass surfaces. These coatings increase light absorption and improve energy conversion efficiency. Vacuum coatings are also utilized for protective coatings on energy-efficient windows and thermal insulation coatings for energy systems.

Medical Devices and Equipment

Vacuum coatings are critical in the medical industry to improve the performance and longevity of medical tools and devices. They provide wear resistance and lubricity to surgical instruments, corrosion protection for implants, and biocompatible coatings for medical devices like stents and catheters.

Packaging and Decorative Coatings

Vacuum coatings are used for decorative purposes, such as creating metallic finishes on jewelry, watches, and luxury goods. They are also applied to provide barrier coatings on packaging materials to enhance the shelf life of food and pharmaceutical products.

Related to the CNC machining business, the best examples are the cutting tool’s coating to make those tools last longer, resist higher temperatures, and cut stronger materials.

Advantages of Vacuum Coating

Precise Thickness Control: Vacuum coating allows for precise control over the thickness of the deposited coatings. This level of control ensures uniformity and consistency, which is critical for achieving desired functional and optical properties.

Enhanced Surface Properties: Vacuum coatings can enhance the surface properties of materials by providing them with desirable characteristics such as hardness, wear resistance, lubricity, corrosion resistance, and anti-reflectivity. These properties can improve the durability, performance, and aesthetics of coated surfaces.

Improved Product Durability: Vacuum coatings offer excellent protection against wear, friction, corrosion, and other environmental factors. By adding a thin protective layer, vacuum coating extends the lifespan of products, reducing the need for frequent replacements and improving overall durability.

Versatility in Material Selection: Vacuum coating techniques can be applied to a wide range of materials, including metals, alloys, ceramics, and polymers. This versatility allows for the customization of coating properties to suit specific applications and material requirements.

Conclusion

In conclusion, vacuum coating is a versatile and valuable technology that offers numerous advantages in various industries. It allows for precise control over coating thickness, enhances surface properties, improves product durability, and enables customization of material selection.

Despite its advantages, vacuum coating does have limitations, including high initial setup and maintenance costs, limitations on coating area, and process complexity. However, with careful consideration of these factors and proper implementation, the benefits of vacuum coating can outweigh these limitations.

As part of our processing services, Capable Machining provides various vacuum coating services. We provide vacuum coating technology through our own complete supply chain so that we can provide full-chain services from machining to various surface treatments.

Please, explain more in detail

Today I was specially registered to participate in discussion.

I apologise, but, in my opinion, you are not right. Let’s discuss. Write to me in PM, we will talk.