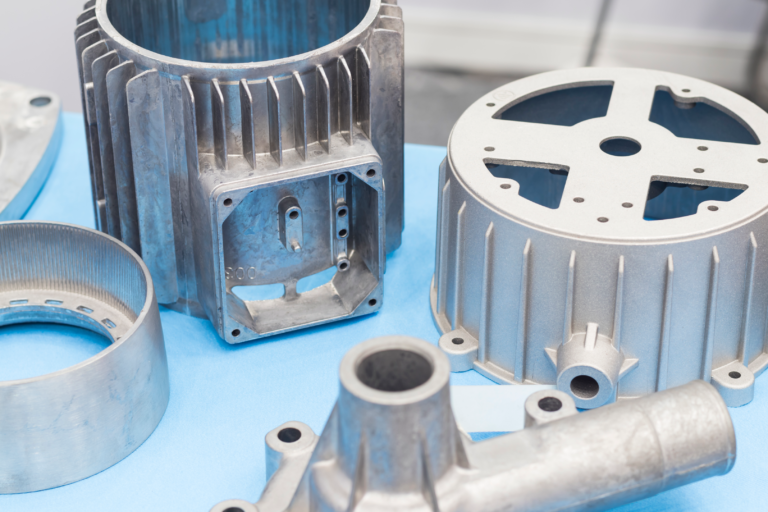

What is Die Casting Mold?

Mold is Important for Die Casting Types of Die-Casting Molds Prototyping dies High-pressure die casting prototyping dies Production dies Unit dies Trim dies Mold Design Process Preliminary phase Number of Cavities Projection Area Product Volume and Shape Injection channels Type…