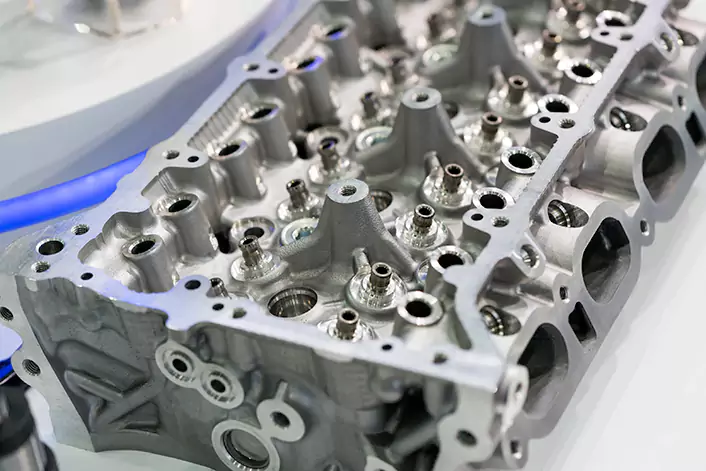

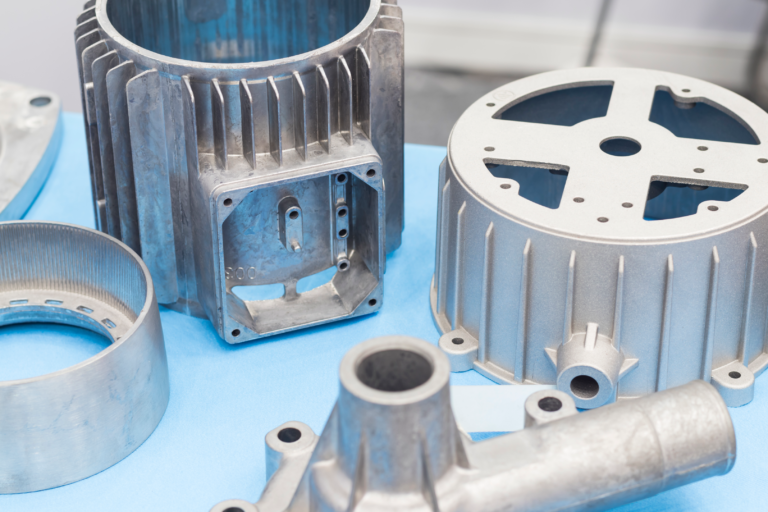

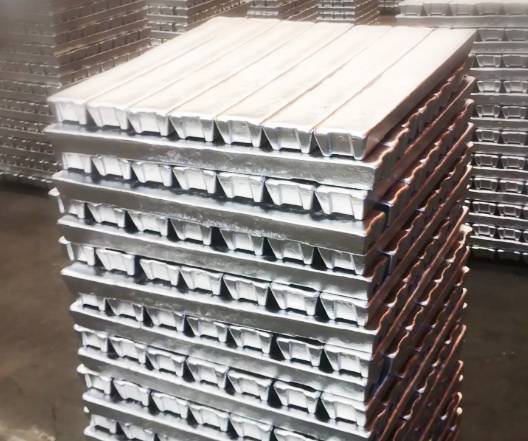

Automotive Die Casting and Casting Aluminum Alloys

Aluminum alloy has a series of excellent performance and highly efficient energy saving and environmental protection effects, the application of aluminum alloy in automobiles and motorcycles is more and more, and the proportion in the structure of the material used…