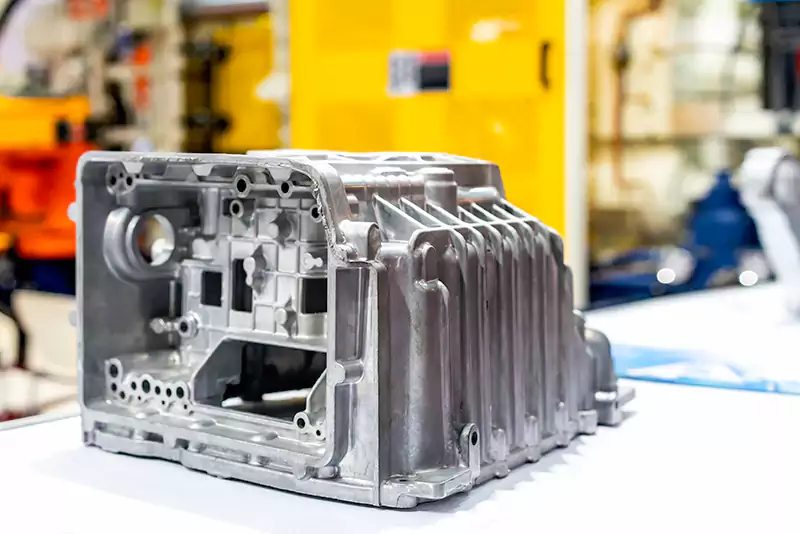

What is Die Casting Mold?

A die-casting mold (die) is a type of tool used to manufacture metal parts through the die-casting process. The die-casting process is a method of metal casting in which molten metal is injected under high pressure into a mold cavity. The die-casting mold is typically made of steel and is designed to shape the metal into the desired part.

Mold is Important for Die Casting

The shape, size, quality, and smoothness of die-casting production of die-casting parts are closely related to die-casting molds, so it is very important to design die-casting molds correctly and reasonably. A proper mold design can boost the product’s time and efficiency. The quality of the mold structure determines whether production will proceed smoothly and whether castings will be of the best quality.

Various factors in the production process must be considered in the design of die-casting dies. Therefore, the structure of the casting must be analyzed in the design process. In addition to mastering the filling conditions, implementing key process parameters, and considering other economic impacts, other aspects must also be mastered. By doing so, the die-casting mold can meet the basic production requirements.

Types of Die-Casting Molds

In die casting, there are several types of tooling, each with different functions.

Prototyping dies

Custom-made dies are a crucial investment in die casting. Therefore, a prototype die helps to avoid expensive mistakes, by making a small number of casts to test. Alternatively, prototyping strategies include gravity casting, machining, and 3D printing. However, they involve trade-offs on properties, tolerance, and design.

High-pressure die casting prototyping dies

Prototypes made by high-pressure die casting are the most suitable option whenever you require the same alloy, properties, process, and geometry for production. It is possible to manufacture prototype dies from pre-hardened, uncoated tool steels and standard components. Therefore, they can be produced in a short period of time and at a reduced cost as a result.

The ejection and cooling techniques used by these molds are less efficient than those used in a production die-casting mold. And hence the tool won’t last as long either, and the die won’t be as efficient as a production die. It will not be an issue if you only need a small amount of casting to test.

Production dies

These are the most common types of dies used in die casting. When the design has been finalized and the product is ready for launch, production dies are needed.

We can have:

Single-cavity dies with no slides

Multiple-cavity dies with several slide options

Most often, a holder block holds the cavity material, which is high-quality steel. The design of production dies ensures that they have critical dimensions. In this way, you can be sure that they are able to handle the machining specifications that you require.

Unit dies

Unit dies are discrete dies that are often quite small and are designed to be put into a larger master holding die. In most cases, the master die will be a fixed member, but the unit dies will be altered so that different components can be made. The majority of the unit dies will be single cavity dies, and their components will include cover halves and an ejector. Changing the die inserts allows unit dies to be utilized for the production of a wide variety of components while requiring just a relatively little initial investment.

Trim dies

For high-volume production, CMW uses trim dies and production dies. After casting, the trim die cuts off the flash, runner, and overflow. Some trim dies to need hydraulic operated motions or cams, whereas others require open and close functions to remove the flash effectively.

Part geometry prevents the ability to remove flash completely with a trim die. This can be addressed with hand de-flashing strategies and custom trimming.

Looking for modern-looking, stronger, and more durable parts? Choose the die-casting process with tooling to produce your end-use parts. The good news is that CapableMachining offers one-stop die-casting services.

Mold Design Process

In this section, we will examine the process involved in designing a mold for a high-pressure die-casting project. The process has five broad categories:

Preliminary phase

Die-casting technology is essential for checking the part’s manufacturability before designing the mold. This phase involves judging the practicability of the product from a geometrical and dimensional.

Dimensional View

There is a need to know the dimension of the part and the number of cavities required for each casting. This will help determine the opening force and volume of the casting. Knowledge of this data will make feasibility studies a lot easier.

Geometrical View

The geometry of the parts includes drawing the parting line. Using a parting line, die-casting molds can be opened easily and castings can be ejected easily. Furthermore, the surface of parts depends on their position from parting lines. Thus, surfaces must be designed in the direction of mold openings.

Due to shrinkage caused by metal cooling, geometric tolerances found on the 2D model are tough to produce. A higher number of quotes means it is more difficult to get the same value on the casting. Therefore, you can continue with the die-cast mold design as soon as you confirm the part’s manufacturability.

Number of Cavities

When determining the number of cavities, you must take into account the number of pieces to be produced, the orientation of the cavities, and the hypothetical cycle time. By doing this, you will be able to determine whether to use a multi-cavity mold or a single-cavity mold.

Remember that the production process might be affected by the cavity’s dimension and product disposition when choosing a multi-cavity mold. Aside from the ejection phases and complexity of filling, a multi-cavity mold also increases ejection phases.

Projection Area

Surfaces created by cavity projections on a plan are called projection areas. It is perpendicular to the direction of the mold opening. The projection area is a vital component of the design phase. It relates the opening force from the molten metal to the die walls. As a result, the strength of the force will depend on the orientation of the dimensions of the shape. A strong force will cause an overflow of materials, resulting in the formation of burrs.

Therefore you need to estimate the forces produced by the molten metal to prevent this casting defect. The force is the product of specific machine pressure, projection area, and pre-set safety factors. A wider margin of margin helps counter the maximum pressure after filling. Many people refer to it as a water hammer.

The machine transfers dynamic and static forces at the end of the process. In this way, pressure picks are produced, which must be absorbed by the closing machine force. The closing force is determined by the stroke dimension and the press model.

Product Volume and Shape

Mold design depends on the volume and shape of the product. Additionally, keep in mind that the large parts will shrink due to a longer cooling time, increasing shrinkage. Therefore, there is a need to size the mold cavities accordingly.

Variables can also affect the final mold size. The most important factors to consider are:

Injection channels

The size of injection channels varies with the number of cavities and the position of gates and pieces. There are some fluid dynamics requirements that have to be met when designing injection channels. When moving in the direction of the molten metal, manufacturers decrease the section to ensure that it adheres correctly to the mold wall. Due to shrinkage, there is an accelerated flux, and they’re detached from the walls. There will be less turbulence, air trappings, and other problems if the external layer is smoother.

Type of die closing

Open/close mold closing is the plainest die closing. Ideally, it is suitable for products with clean, simple shapes that can be easily ejected. Nevertheless, it is not the best option for parts with complex geometries. It would be difficult to remove products with complex geometry, so the manufacturer would need to increase the die size.

Presence of overflows

Overflows are small wells designed in strategic parts of the die-cast mold. As first metal shots are often colder than later ones, they are important. As a result, you can avoid cold laps and other similar aesthetical defects. Additionally, overflows increase the die temperature in critical casting areas by acting as heat sources.

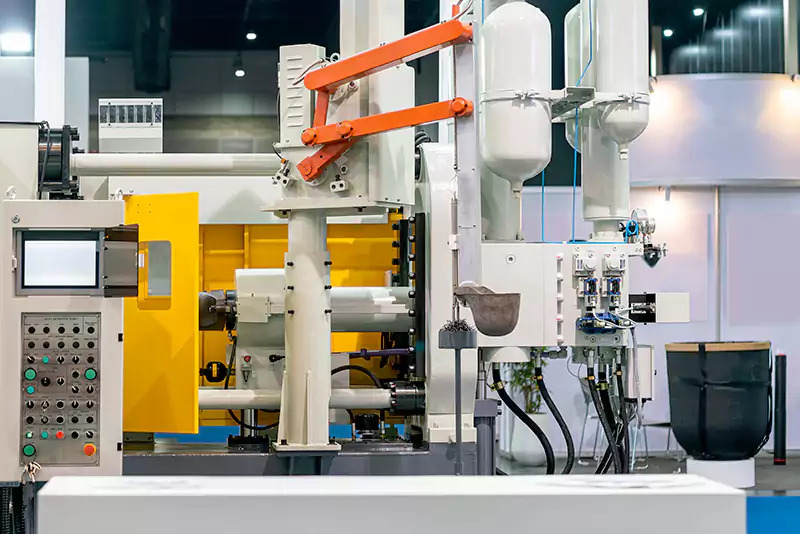

Die Casting Machines

Besides die-casting mold, machines are also essential to this process. A die-casting machine is a specialized piece of equipment used to manufacture metal parts through the process of die-casting. Die-casting machines use high pressure to inject molten metal into a mold cavity, where it solidifies and takes the shape of the mold.

When using die casting machine, some key features and components are worth noticing.

Injection system

The injection system is responsible for delivering molten metal into the mold cavity. It typically includes a furnace or melting pot to melt the metal, a shot chamber to hold the molten metal, and a plunger or piston to inject the metal into the mold cavity.

Clamping unit

The clamping unit is used to hold the two halves of the mold in place during the casting process. It typically includes a hydraulic or mechanical system to apply pressure to the mold and keep it closed during the injection.

Control system

The control system is used to monitor and adjust the various parameters of the die-casting machine, such as injection pressure, injection time, and cooling time. It may be operated manually or through computerized controls.

Cooling system

The cooling system is used to regulate the temperature of the mold and the metal during the casting process. It typically includes water channels that circulate coolant through the mold to extract heat from the metal as it solidifies.

Conclusion

In conclusion, die-casting molds are an essential component of the die-casting process. They play a critical role in determining the quality and consistency of the final product, as well as its overall cost-effectiveness.

By understanding the various types of molds available, their advantages and disadvantages, and how to properly design and maintain them, manufacturers can optimize their die-casting operations and achieve greater success in today’s competitive marketplace. Whether you’re new to die casting or a seasoned industry veteran, it’s important to stay up-to-date on the latest advancements and best practices in mold technology to ensure your products are produced at the highest level of quality possible.

CapableMachining has over 10 years of experience in die-casting mold and die-casting processes. If you got any questions in this regards, send us an email, we are glade to answer.