Ontario

Various 5-axis high-precision CNC machining equipment, we can provide high cost-effective precision CNC machining services in California.

CNC Machining services for Ontario, California

Get high-quality, and professional engineering service from an experienced manufacturer.

Custom Parts, On Demand Manufacturing

Welcome to CapableMachining, your premier source for CNC machining services. With our expertise and state-of-the-art technology, we offer unparalleled precision and efficiency in delivering high-quality machined parts. Trust us to meet your CNC machining needs with excellence and reliability.

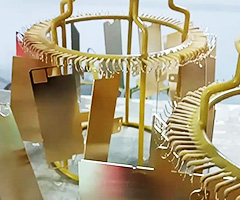

CNC Milling

in Ontario

We use 3-axis, 4-axis, and 5-axis CNC milling to manufacture parts from more than 40 different plastics, metals, and rubbers. For small and massive volume production, first article inspection (FAI) is available upon request. Tolerance up to +/- 0.0004”(0.01mm). You can also get competitive prices for various additional heat treatments (aging, aneal, quenching, temper, and more), and surface treatments (anodizing, chromate plating, passivation, etc.).

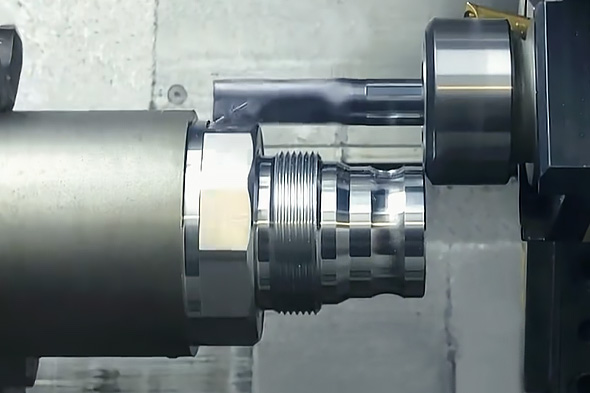

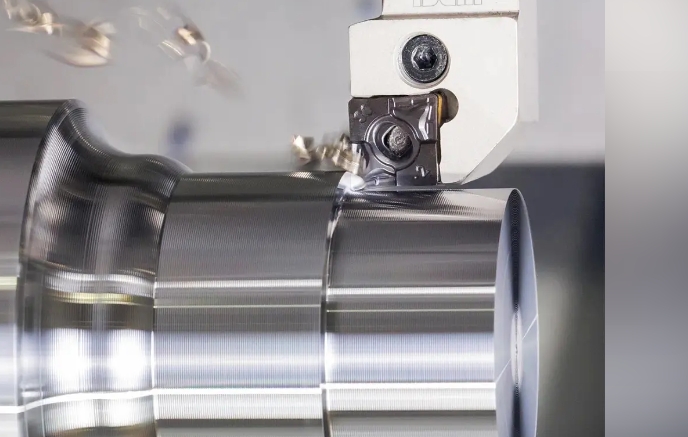

CNC Turning

in Ontario

CNC Turning and CNC Turn-Mill machining often provide better precision and speed for parts with primary cylindrical features. We use CNC lathes with multiple turning tools, ensuring fast and accurate manufacturing, particularly good at making parts primary to be a cylinder but with complicated features like flats, slots, and holes. Maximum Diameter: 500mm or 19.7-inch; Maximum Length: 1800mm or 70.9-inch;

General Workflow of CNC for Ontario

1. Select a service and upload files

2. Get engineer feedback and quote

3. Manufacturing Start

4. Parts are delivered

CNC machining surface finishes in Ontario

We prioritize customer fulfillment by providing a range of secondary processing options, such as spray painting, silk screen printing, laser engraving, and other services, to enhance their overall experience.

Materials

Picking the right materials is critical , encompassing considerations like cost, processing complexity, and potential surface treatments. Our skilled engineering team is adept at proactively addressing this challenge, even before orders are placed. This approach ensures our customers have the utmost possible belief in the final quality of their products. We strive for professional and informative communication to meet our clients’ needs.

Metal

We have trained material technology engineers to provide you with instant quotes for over 100 metals, like carbon steel, tool steel, aluminum, brass, etc, and to compare prices for different processed materials.

Plastic

We cooperate with large material suppliers and are able to offer instant quotes for over 200 high-quality plastics and compare prices for different processed materials for you. Good materials are the foundation of quality.

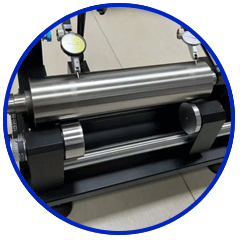

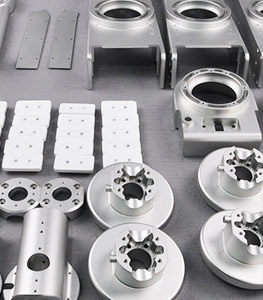

Our Quality Control

CapableMachining boasts a well-established quality assurance framework and a team of skilled technical engineers who diligently oversee every aspect of our product manufacturing process – from acquiring excellent raw components to delivering impeccable finished goods that encompass metals and plastics. To uphold our commitment to superiority, we extensively utilize advanced testing technology and cutting-edge equipment to meticulously evaluate crucial parameters such as workpiece dimensions, hardness, tensile strength, and elongation at every stage of production. We strive to maintain utmost control over these data points to consistently meet and surpass the expectations of our esteemed clientele.

Professional quality control Engineer

Tolerances up to ±0.0004″ (0.01mm)

State-of-the-art Inspection Facilities

Proven and reliable quality control system.

Other capabilities

- Free & Automatic DFM feedback

- Tolerances: typically +/- 0.15mm or +/-0.006 inch

- Tooling: 30 days

- Free advices from high trained engineers.

- Quotation in a few hours.leading time 3 days

- Fast delivery time

- Tolerances: typically +/- 0.15mm or +/-0.006 inch

- Free consultant ,Free DFM feedback

- Casting lead time: 5~7 days

- Wide range of material choices

- Free consultant from engineers

- Fastest leading time: 1 day

- Free & Automatic DFM feedback

- Tolerances up to ±0.00078″ (0.02mm)

- Rapid tooling: 7~12 days

From [quick|fast|speedy] prototyping to [large-scale|mass] production, we specializse in manufacturing products with complex geometries and stringent aesthetic standards. With the expertise of skilled professionals and the capability of advanced technology, we offer comprehensive on-demand manufacturing services. Skilled knowledge enables us to meet a wide range of manufacturing requirements from our clients, ensuring precision, complexity, and aesthetics.

Other Location Near me

FAQ

How to Get CNC Machining Services in California

California is home to a wide range of industries, including aerospace, automotive, and electronics, all of which rely heavily on CNC machining services. CNC machining, or computer numerical control machining, is a manufacturing process that uses computer-aided design (CAD) and computer-aided manufacturing (CAM) programs to control machinery and create complex parts and components with precise accuracy.

If you are in California and are in need of CNC machining services, here are a few steps you can follow to find the right service provider for your needs.

Firstly, start by conducting a thorough online search for CNC machining services in California. Use search engines, industry directories, and online platforms to gather a list of potential service providers. Look for companies that have a good reputation, years of experience, and positive customer reviews.

Next, narrow down your list by considering your specific requirements. Determine the type of materials you need to be worked on, the complexity of the parts, and the volume of production. Some CNC machining companies specialize in certain industries or materials, so make sure to choose one that aligns with your needs.

Once you have shortlisted a few potential CNC machining service providers, contact them to discuss your project in detail. Ask about their capabilities, machinery, and lead times. A reputable CNC machining company will be transparent and open to answering all your questions.

Furthermore, ask for samples or references from previous clients. This will give you an idea of the quality of their work and their ability to meet deadlines.

Lastly, compare quotes from different CNC machining companies. While cost shouldn’t be the sole determining factor, it’s important to consider all aspects, including price and lead time, before making a final decision.

In conclusion, finding reliable and high-quality CNC machining services in California requires thorough research and careful consideration of your specific needs. By following the steps outlined above, you can ensure that you find a service provider that can deliver the precision and expertise required for your project. So, begin your search today and explore the numerous CNC machining options available in the golden state.

Olivia: brass decorative hardware by your CNC machining services have proven to be a game-changer for us. The precision and conductivity of these components have greatly contributed to the reliability of our systems. We look forward to future collaborations.

Uzair: Your CNC machining services played a crucial role in creating the aluminum enclosures we needed. The intricate design and flawless execution speak volumes about your capabilities. These parts have seamlessly integrated into our products, enhancing their functionality.