Electronics

our guarantee

Prototyping and Rapid production for

Electronics Industry

We have rich manufacturing experience and can produce related supporting products for the electronics industry, which can bring your products to the market faster.

Why do Electronics Companies Choose us?

We serve manufacturers of a wide range of electronics, connectors, communication components, and IoT with specialized capabilities that help them improve the quality of their products. Our extensive expertise in electronic prototyping and manufacturing processes helps us meet the needs of each unique customer.

Professional ability

Under the premise of creating the greatest value for our customers, we ensure that your products are manufactured with the most suitable materials and technologies by our professional technical capabilities and various processing capabilities (e.g. CNC machining, sheet metal fabrication, die casting, etc.).

Experiences

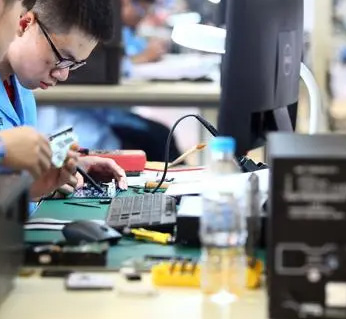

We have a team of people who have been immersed in the manufacturing and processing industry for many years, including skilled workers, mechanical engineers, quality supervisors and so on. We can solve the difficulties encountered in the manufacturing process and provide customers with satisfactory products.

Precision Machining

The manufacture of precision parts requires not only sophisticated equipment, but also specialized operators, accurate inspection equipment, and more. Our capabilities allow us to produce parts with tolerances up to +/- 0.0004”(0.01mm). Providing our customers with satisfactory products is our goal.

Abundant resources

The product from design to become a finished product is a complex process, which requires the cooperation of various resources. We have abundant manufacturing resources in Shenzhen, China, which can help customers solve various problems in manufacturing.

Prototyping & Production Solutions

Products from prototype manufacturing to production of finished products, mainly need to go through the following processes, in the actual product development process, there may be cross-over and overlap between the processes, the specific process and order will vary according to the type and complexity of the product.

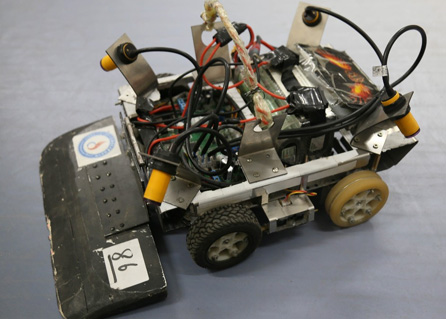

Prototyping

Prototyping is an important part of the product development process that helps product managers, designers, developers, and others to better understand the functionality, performance, usability, and security of a product.

Our engineers will stay in close communication with you to evaluate and optimize your designs, and we’ll bring your early designs to life by building prototypes using production-grade materials to make sure they’re fully functional and ready for testing! Prototyping can be done in the following ways commonly:

Metal prototyping: using cnc machining, sheet metal fabrication, welding and other tools to create prototypes.

3D printed prototypes: prototypes are made using 3D printers.

Of course, you can choice your way.

Engineering Validation & Testing

Our prototypes are designed to mimic the final product, providing you with a clear visual representation of the design so that any potential problems can be easily identified, analyzed and fine-tuned to meet the design objectives, and of course, the last opportunity to make changes to the design and prototype.

The EVT phase performs a variety of tests depending on the application of your product and the environment in which it operates..

Elements vetted during EVT:

Includes: Conformance test, Thermal test, Power measurement test, Signal quality test, Electromagnetic interference test.

Design Validation & Testing

The purpose of Design Validation is that we need to prove that all the features of the product will fulfill the user’s needs. Our experts can test your prototype, work with you and provide in-depth feedback to help you evaluate its performance and appearance.

Design validation refers to the testing of products on the basis of product engineering validation to ensure that the product can meet the user’s needs by testing the user experience, use effect and so on.

Includes: function test, performance test, reliability test, and safety test.

Production Validation & Testing

The main purpose of Production Validation and Testing is to test all molds, equipment, tools, fixtures, test tools, etc. before formal production, and PVT is the final stage before mass production begins. It must be in place and verified before the production pilot can start. We have the expertise to ensure that products are manufactured and tested in a reliable and efficient manner.

PVT

At this stage, the focus is on optimizing various production details such as line speed, operator expertise, quality inspector testing methods and accuracy, product scrap rate, and daily output.

Mass Manufacturing

From people, machines, materials, system and environment we have a sophisticated factory management system that ensures that customer orders are quickly produced and tested in our factory.

With advanced manufacturing techniques and management capabilities, we will take your customized products to the next level. Our team is committed to ensuring that your products meet quality and performance requirements, keep costs low and lead times short.

- Rigorous precision machining

- Unrivaled post-processing operations

- Comprehensive quality control system

Testing & Acceptance

Capablemachining is committed to continuously improving and optimizing all manufacturing capabilities from prototype to production, enhancing every aspect of the quality control process, and ultimately providing customer satisfaction.

Quality control

We have a mature quality assurance system and professional technical engineers to ensure that all products from raw materials to finished products. We also have the most advanced quality testing technology and testing equipment to test the dimensions, hardness, tensile strength, and elongation of workpieces throughout the entire production process to ultimately satisfy the needs of our customers.

Which Electronic Companies are Served by us?

We serve manufacturers of a wide range of electronics, communication components, and IoT with specialized capabilities that help them improve the quality of their products. Our extensive expertise in electronic prototyping and manufacturing processes helps us meet the needs of each unique customer.

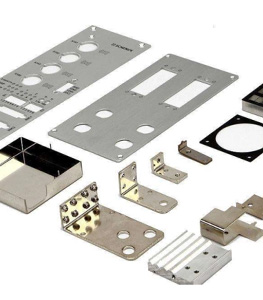

Manufacturing Capabilities

With capabilities in CNC machining, injection molding, sheet metal, 3D printing, Die casting and mold making, we are able to provide you with electronics peripheral manufacturing services to meet your custom electronics needs, including rapid prototyping, custom fixtures and tooling, and low-volume and volume production needs.

CNC machining

In Electronic Industry

Advantages: Diversification, high-precision manufacturing, high production efficiency

- Electronic parts

CNC machines can be used to manufacture a variety of parts used in electronic devices, including precision metal and plastic parts. These parts may include connectors, sockets, heat sinks, brackets, etc.

- Mold making

Plastic housings and components used in electronic devices often require molds to be injection molded. CNC machining is used to make the mold parts of these injection molds.

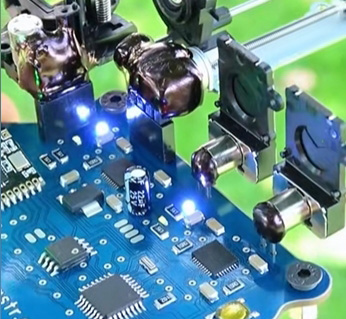

- Customized circuit board tooling

CNC machining can precisely cut and machine brackets and fixtures used to mount and support PCBs.

- Precision hole processing

Electronic devices often require precise hole locations and diameters, and CNC machines can be used to drill, ream, and cut holes.

Rapid Prototyping

In Electronic Industry

Advantages: rapid manufacturing, high-precision manufacturing, complex structure manufacturing

- Consumer electronics

Manufacture of cases, antennas, sensors, and other components for consumer electronics such as smartphones, tablets, and wearable devices.

- Industrial electronics

Manufacture of components for industrial electronics such as motors, transformers, and circuit boards.

- medical electronics

Manufacture of medical electronics such as implantable medical devices and wearable medical devices.

- aerospace

Manufacture of drone wings, components for airplanes, rockets and other aerospace products.

Injection molding

In Electronic Industry

Advantages: high production efficiency, high-precision manufacturing, diversified design

- Consumer electronics

Injection molding is used to manufacture housings, structural parts, and functional parts for consumer electronics products such as smartphones, tablets, TVs, and wearable devices.

- Industrial electronics

Manufacture of structural and functional parts for industrial electronic products such as motors, transformers, circuit boards, etc.

- medical electronics

Manufacture of housings, structural parts, functional parts, etc. for medical equipment.

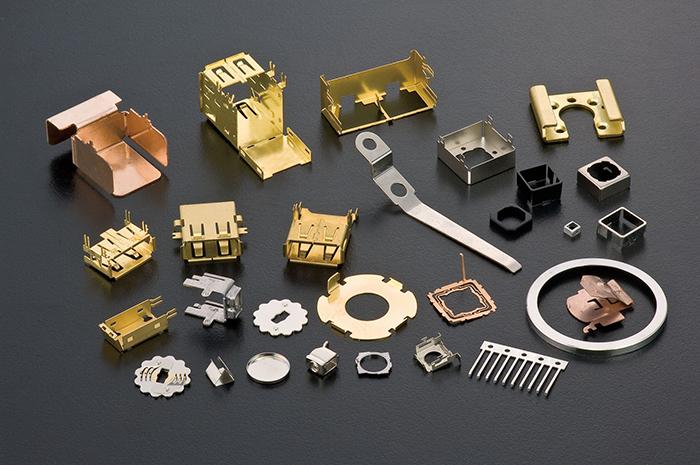

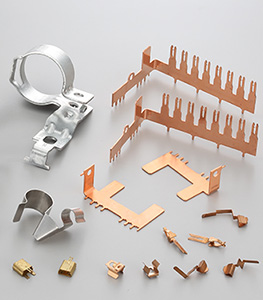

Sheet Metal Fabrication

In Electronic Industry

Advantages: low cost, flexible processing, high production efficiency

- Consumer electronics

Manufacturing casings, antennas, radiators, buttons, structural parts, functional parts, etc. for consumer electronics products such as smartphones, tablets, TVs, and wearable devices.

- Industrial electronics

Manufacturing structural parts, casings, brackets, radiators, functional parts, etc. for industrial electronic products such as motors, transformers, and circuit boards.

- medical electronics

Manufacture of casings, structural parts, functional parts, etc. for medical equipment

Die Casting

In Electronic Industry

Advantages: low cost, flexible processing, high production efficiency

- Consumer electronics

Manufacturing casings, structural parts, functional parts, etc. for consumer electronics products such as smartphones, tablets, TVs, and wearable devices.

- Industrial Electronics

Manufacturing structural parts and functional parts for industrial electronic products such as motors, transformers, and circuit boards.

- medical electronics

Manufacture of housings, structural parts, functional parts, etc. for medical equipment.

Related Blog

Application and development trend of rapid tooling manufacturing

As people’s quality of life has improved, the demand for various products has increased, and r…

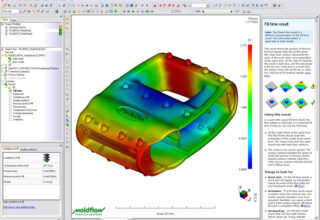

How to analyze and optimize the mold flow of injection molded parts?

A set of high-quality injection molds is inseparable from reasonable design and exquisite processing…

Modern injection mold manufacturing technology and its development trend

In modern industry, there is a very crucial field called the mold industry. Mold technology is indis…