Modern injection mold manufacturing technology and its development trend

In modern industry, there is a very crucial field called the mold industry. Mold technology is indispensable for the design and manufacture of many new products, especially in the fields of automobile, light industry, electronics, and aerospace. The development of mold technology is crucial to the growth of the mold industry, which involves the intersection and application of various disciplines. With the development of the economy, mold technology has become an important symbol to judge a country’s production level.

Many countries, especially some economically developed and technologically leading countries, attach great importance to the research and development of mold manufacturing technology and actively promote the development of the mold manufacturing industry. They widely use a variety of technologies and advanced equipment to improve and optimize the mold manufacturing process in order to improve the quality of the mold, which is crucial for the rapid development of the national economy and society.

Computer-aided processing using advanced technology

High-efficiency mold processing technology

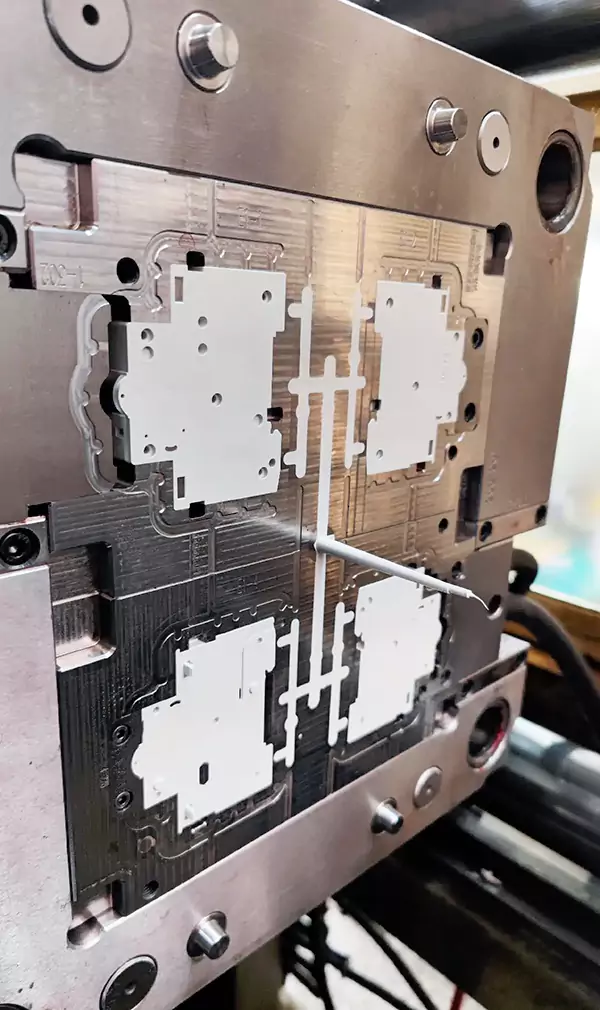

Almost all mold processing now uses microcomputer control computer programs. These systems must be very reliable, and each functional system has a standard program. Mold processing mainly includes rough milling, tempering heat treatment, fine milling, EDM, high-speed CNC milling, drilling, grinding, and other processes. Modern processing technology includes five-axis high-speed milling, profiling drilling, etc., but these processing processes are inseparable from computer-aided design and programming control.

High-speed CNC grinding manufacturing technology

High-speed CNC grinding machines have the advantages of large grinding volume, high dynamic accuracy, high vibration resistance, and good stability. The whole use process requires a high degree of automation and reliability. To improve the grinding quality, it is necessary to use grinding wheels with high mechanical strength and equipped with a good cooling system.

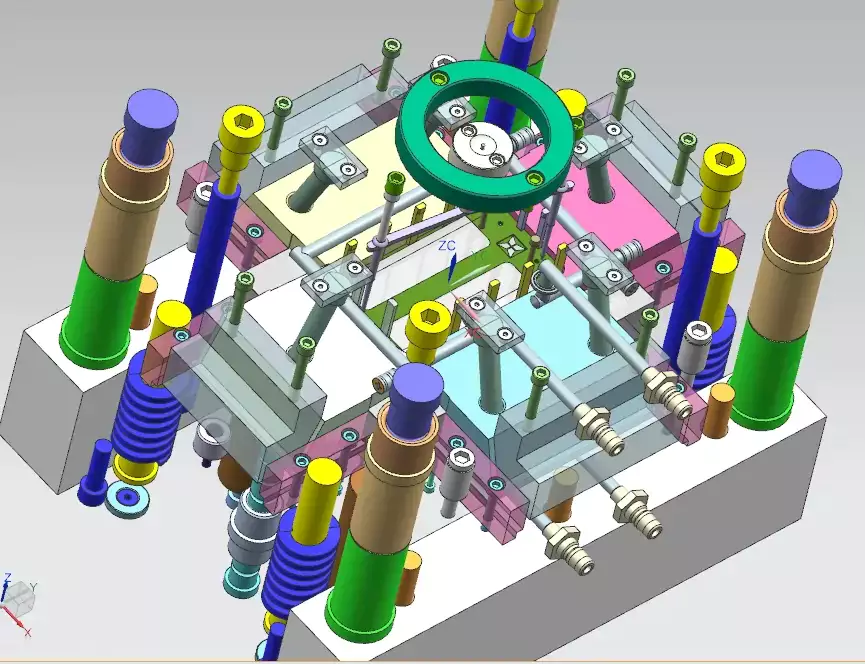

Three-dimensional control mold design, evaluation, and manufacturing technology

Mold design in the past could not meet the requirements of modern production. Therefore, advanced technologies are needed to evaluate, identify, and produce diverse mold design solutions. The use of three-dimensional program-controlled data process modeling software allows for mold design data analysis, mold condition assessment, and simulation during digitally controlled cutting processes.

Integration of 3D Cavity and Mirror EDM

During the EDM process, solid fine powder can be added to the working medium in order to improve the quality of the process. This reduces the capacitive effect and increases the dispersion of the discharge path.

Mold and manufacturing technology development trend

Mold software in the trend of networked applications

With the development of globalization, mold companies are rapidly developing in competition, cooperation, production, and management. In this social context, virtual design and flexible production techniques have become very important. Modern integrated systems include mathematical modeling, reverse engineering construction, industrial design, and other functions, which can realize the unification of specialization and openness.

Integrated mold digital control software functions

The integrated functions of digital control software can manage and control the mold design, assembly, performance verification, operational testing, and production process to achieve maximum operational profit.

Trends in Intelligent Mold Software

Utilizing the new generation of mold software and CAD modeling allows for a fully automated design and production process, as well as improved quality and efficiency of the mold.

Conclusion

In the modern society of rapid development of science and technology, mold technology is not only a key component of advanced production technology but also an important field of application of advanced production technology. Advanced mold manufacturing technology can promote the development of information technology and control technology, improve production efficiency, and contribute to the scientific and technological innovation of the country.

One comment

Leave a Comment

You must be logged in to post a comment.

I am not sure where youre getting your info but good topic I needs to spend some time learning much more or understanding more Thanks for magnificent info I was looking for this information for my mission