Theoretically speaking, 3D printing technology can print any material,

but currently 3D printing materials mainly include metal materials, polymer materials and ceramic materials, among which plastic is still the most used material,

but metal materials are growing rapidly, and their utilization rate is increasing It’s about 36%.

The application prospect of 3D printing still depends on the research and development of printing materials and its marketing promotion.

Material |

Color |

Temperature resistance |

Paintable |

Hardness |

Viscosity cps( 25 ℃) |

Density g/cm3(25℃) |

Layer Height (mm) |

Bending Strength (Mpa) |

Tensile Strength (Mpa) |

|---|---|---|---|---|---|---|---|---|---|

| White Resin JS-UV-HP-02 |

White | 30℃ – 40℃ | Y | 76-85 | 360-420 | 1.11-1.14 | 0.05-0.12 | 60-75 | 25-30 |

| Yellow Resin JS-UV-2016-XLST |

Yellow | 30℃ – 40℃ | Y | 76-85 | 360-400 |

1.11-1.14 | 0.05-0.12 | 60-75 | 25-30 |

| Black Resin | Black | 30℃ – 40℃ | Y | 76-85 | 360-400 |

1.11-1.14 | 0.05-0.12 | 60-75 | 25-30 |

| Translucent Resin | Colorless | 30℃ – 40℃ | Y | Hazy feeling, the surface texture is similar to that of white resin | |||||

| Translucent Resin | Colorless | 30℃ – 40℃ | Y | Hazy feeling, the surface texture is similar to that of white resin | |||||

Material |

Color |

Temperature resistance |

Paintable |

Specifications |

|---|---|---|---|---|

| PA12 Black | Ash Black | 100℃ | N | Stable color Accurae size High reusability |

| PA12 White | Bright White | 100℃ | N | Stable color Accurae size High reusability |

| PA12 30% GF | Grayish Yellow | 100℃ | N | High strength Heat deformation resistance High reusability 30% glass |

| PA12 40% Alu | Metallic Grey | 100℃ | N | High strength Wear resistance Metal color High reusability 40% aluminum powder |

Material |

Color(s) |

Tensile Strength (Mpa) |

Elongation at Break (%) |

Tempature Resistancce (°C) |

|---|---|---|---|---|

| ABS-M30 | Black, Dark Grey, Ivory, White | 32 -28 | 7-2 | 96 |

| ABSi | Translucent | 37 | 4.40 | 86 |

| ASA | Black, Gray, Green, Ivory, White | 27 | 9-3 | 98 |

| Nylon 12 | Black | 49.3 -41.8 | 30-6.5 | 91.9 |

| PC-ABS | Black | 41 | 6 | 110 |

| PC | White | 57 -42 | 4.8-2.5 | 138 |

| PC-transparent | Translucent Natural, White | 57 | 4 | 133 |

| PLA | Black, White | 50 -37 | 2.9-1.9 | 55 |

| ULTEM 9085 | Black, Tan | 47 -33 | 5.8-2.2 | 153 |

| ULTEM 1010 | Amber (Natural) | 64 -41 | 3.3-2.0 | 216 |

Material |

Color(s) |

Tensile Strength (MPA) |

Elongation at Break (%) |

Tempature Resistancce (°C) |

|---|---|---|---|---|

| PA11 | Black, Grey | 52 | 50 | 54 |

| PA12 | Black, Grey | 48 | 20 | 95 |

| PA12 GB 40 | Black, Grey | 30 | 6.50 | 120 |

Material |

Density (g/cm3) |

Tensile Strength (MPa) |

elongation after break (%) |

Vickers Hardness (%) |

Features |

|---|---|---|---|---|---|

| Stainless Steel-316L | ≥7.90 | 480-580 | ≥40 % | ≥180 | High Hardness and Toughness Strong corrosion resistance better machinability Can be high gloss polished |

| Nickel-Chromium-In 718 | ≥8.18 | 1230-1430 | 12%-20% | ≥410 | Ease of processing It has high Tensile Strength, fatigue strength, Creep strength and breaking strength High oxidation resistance at 1000°C Stable chemical properties at low temperatures Good welding performance, strong corrosion resistance |

| Cobalt Chromium-CoCr | ≥8.35 | 980-1080 | 7%-10% | ≥350 | Excellent finished surface high toughness high strength Excellent biocompatibility good corrosion resistance |

| Aluminum alloy-AlSi10Mg | ≥2.65 | 400-460 | ≥5 % | ≥120 | Build parts with excellent mechanical properties, Such as Hardness and Tensile Strength excellent corrosion resistance Good thermal and electrical conductivity High dynamic toughness |

| Titanium alloy-TC4 | ≥4.40 | 1050-1150 | 4%-8% |

≥310 | High strength to mass ratio Strong corrosion resistance Good biocompatibility and osseointegration Small thermal expansion, low thermal conductivity better machinability |

| Tin Bronze alloy-CuSn10 | ≥8.78 | 460-520 | ≥20 % | ≥115 | Seawater cavitation resistance, good corrosion resistance Good wear resistance better machinability Good thermal conductivity non-magnetic |

Material |

Color(s) |

Tensile Strength (MPA) |

Elongation at Break (%) |

Tempature Resistancce (°C) |

|---|---|---|---|---|

| PA11 | Black, Grey | 52 | 50 | 54 |

| PA12 | Black, Grey | 48 | 20 | 95 |

| PA12 GB 40 | Black, Grey | 30 | 6.50 | 120 |

Material |

Color |

Temperature resistance |

Paintable |

Feature |

|---|---|---|---|---|

| ABS-like | Naturally white and multi colors are available as required. | 40-50℃ | Y | Good Hardness |

| Nylon-like | White | Y | Resilient | |

| Nylon GF-like | Black | 120℃ | Y | Good Strength |

| PC-like | translucent/transparent | 40-50℃ | Y | Resilient |

| POM-like | Naturally white and multi colors are available as required. | 40-50℃ | Y | Good Hardness |

| TPU-like | Color can be adjusted as required | 100℃ | Y | Shore Hardness40-90 |

| Silicone Rubber-like | Color can be adjusted as required | 100℃ | Y | Shore Hardness40-90 |

How to Make the Right Choice

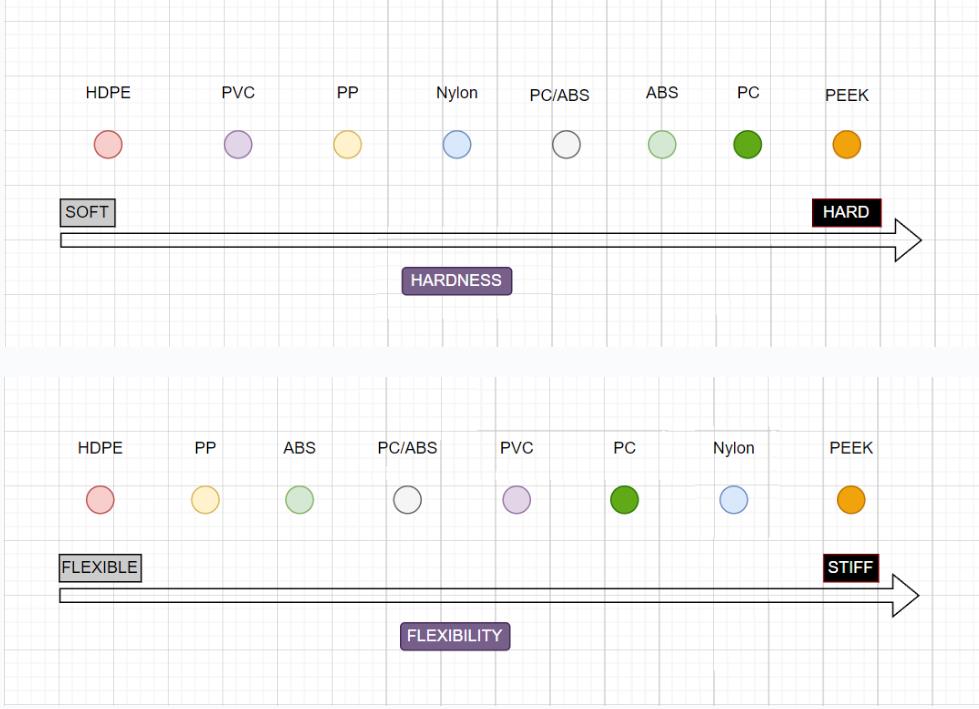

3D printing is a popular industry with a wide range of materials, making it challenging for consumers to select the right material without specialized knowledge.

When choosing a material, it’s essential to consider various factors and how they interact to find an economical and effective option. Some unrealistic expectations, like high strength and toughness at a low cost, may not be feasible for the average consumer.

Factors to consider typically include:

a. The specific use environment, including properties like biocompatibility, heat resistance, and more.

b. Functional requirements, which depend on the intended use of the product.

c. Geometric constraints, which relate to the printing process and material limitations.

d. Scenario utilization, as different parts of a product may require various materials and printing processes.

e. Durability, considering the stress and cycles a printed part will endure.

f. Post-processing methods, which can enhance the final product.

g. Budget, time, and quality trade-offs to find the right balance.

h. Prioritization of these factors to tailor the 3D printing solution to your project’s specific needs.

We offer free consultation services to help you make the best material and process choices for your project.

Reference

International Standard

International standards for 3D printing are important for ensuring consistency and quality in the industry. Here are a few key international standards related to 3D printing:bISO/ASTM 52900, ISO 17296-1, ISO 19085-1, ISO 27628, ASTM F2792.

Other

Materials are an essential basic capability in the industry, and their development can promote technology and innovation and society’s development. The current trend of material development is to be more environmentally friendly and energy-saving.

Related Blog

Automotive Die Casting and Casting Aluminum Alloys

Aluminum alloy has a series of excellent performance and highly efficient energy saving and environm…

12 Design tips for plastic injection parts

Choose the right material Choosing the right plastic material for injection molded parts can be tric…

Plastic Injection Molding Materials

Table of Contents Features And Differences Among Materials Crystalline plastics Non-crystalline plas…

“Customers are our partners, so we prioritize their needs.”

— CapableMaching