In the process of sheet metal processing, as the material will be often folded, extruded, and welded by the machine, and the final product of the sheet metal production itself is often something that needs to be exposed to the air all year round, or even in the open air environment, which corresponds to the corresponding requirements for the material: it needs to have good weldability, good cold plasticity, and good chemical stability.

Aluminum is a light metal, a low melting point, pure aluminum is easy to oxidize, but the tensile strength is better. Surface features: brushed surface, grayish-white color, light hand feel, dark luster.

Typically models: A2024, A2052, A5052, A5754, A6061, A6063, A7075, etc.

Material thickness: 0.3~20mm.

Material width: 5′ (1524mm), generally 4′, i.e. 1219mm or 1250mm, can be cut to any size less than 1524mm as required.

Material length: Can be cut to any size as required. Generally 8′, i.e. 2438mm or 2500mm.

Material Properties:

- Lightweight, metallic white luster, easy to scratch the surface, so the surface is often pasted with PVC protective film; good durability and corrosion resistance.

- Surface treatment: sandblasting, wire drawing, or polishing, followed by anodic oxidation and chromate oxidation.

Stainless steel with different alloy types and content, a wide variety, generally with the atmosphere, acid, alkali, salt and other media corrosion resistance.

Typically models: SUS304 (18-8 stainless steel, non-magnetic), SUS301 (spring stainless steel, slightly magnetic), SUS430 (magnetic, easier to rust)

Tensile strength: above 53kgf/mm2.

Material thickness: 0.1~10.0mm.

Material width: the widest 5′ (1524mm), generally 4′, i.e. 1219mm or 1250mm, can be cut to any size less than 1524mm as required.

Length of material: Can be cut to any size as required. Generally 8′, i.e. 2438mm or 2500mm.

Specific gravity: 7.95

Notes:

1, the general tolerance of the material thickness +0, -0.08, that is, the plate thickness of 2.0mm measured may only be 1.92mm.

2, The measurement of material thickness should be used a micrometer (micrometer), do not use cursor calipers.

Cold rolled sheet is a product made from hot rolled coils that are rolled at room temperature below the recrystallization temperature.

Typically models: SPCC, CRS, SPCD, SPCE.

Hardness: 1/2H=74~89, 1/4H=65~80, 1/8H=50~71, H=89 or more.

Tensile strength: above 28kgf/mm.

Material thickness: 0.25~3.2mm.(Material above 3.2mm must be customized)

Material width: 5′ (1524mm), generally 4′, i.e. 1219mm or 1250mm, can be cut to any size less than 1524mm as required.

Length of material: Can be cut to any size as required. Generally 8′, i.e. 2438mm or 2500mm.

Material Characteristics: Iron gray luster, the surface is easy to scratch, rust, processing should pay attention to the protection and fast turn sequence.

Note:

1, the general tolerance of the material thickness +0, -0.08, that is, the plate thickness of 2.0mm measured may be only 1.92mm.

2, in order to prevent rusting of the plate can be lightly coated with anti-rust oil on the surface of the workpiece after processing, or cover the workpiece with oil cloth.

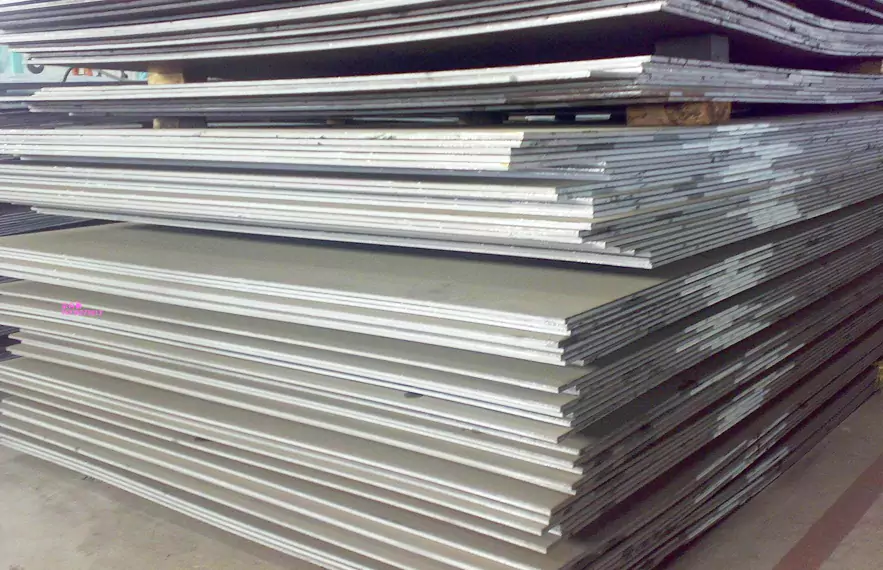

The advantage of hot rolled sheet is that it is hot rolled at high temperature, which makes the grain of steel become finer and makes the steel structure stronger and tighter, with better ductility and stronger loading capacity.

Typically types: SPHC, HRS

Tensile strength: 41~52kgf/mm or more.

Material thickness: 1.4~6.0mm (above 6mm material code SS41)

Material width: 5′ (1524mm), generally 4′, i.e. 1219mm or 1250mm, can be cut to any size less than 1524mm as required.

Material length: can be cut to any size as required. Generally 8′, i.e. 2438mm or 2500mm.

Specific weight: 7.85

Material Characteristics

1、Black and gray luster, the surface is not easy to scratch, but easy to rust spots, processing must pay attention to remove.

2、It is not suitable for electroplating (colorful zinc plating, white zinc plating, nickel plating, tin plating…).

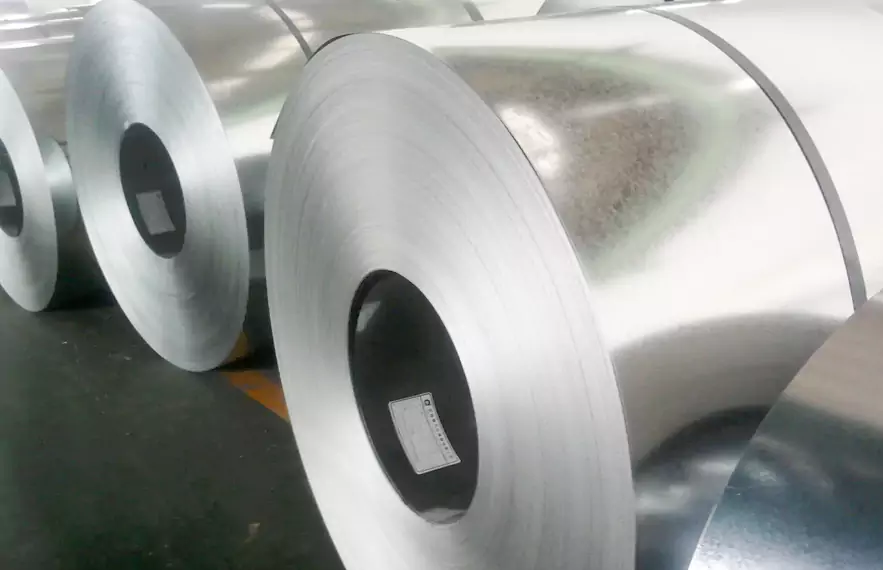

Hot-dip galvanized steel sheet is a kind of thin steel sheet which is immersed in a molten zinc bath to make a layer of zinc adhering to its surface. At present, the main use of continuous galvanizing process production, that is, the coil of steel plate continuous immersion in the molten galvanizing tank, made of galvanized steel;

Its surface is beautiful, block or leaf-shaped plating crystalline pattern, and the coating is solid, with excellent atmospheric corrosion resistance, at the same time, the steel plate has good welding properties and cold forming properties, compared with the surface of the electro-galvanized sheet, its coating is thicker, mainly used for the requirements of corrosion-resistant sheet metal parts.

Typically modles: Zn100-PT, Zn200-SC, Zn275-JY (GB/T 2518-2008)

- White metallic luster, patterned, not easy to rust on the surface, but will produce white rust spots due to corrosion.

- Generally do not do surface treatment

- Can not do plating (colorful zinc plating, white zinc plating, nickel plating, tin plating)

Copper is mainly used as the conductive material, and its surface treatment is nickel-plated, chromium-plated, or no treatment, high cost. The surface treatment is nickel-plated, tin-plated, nickel-plated, or left untreated, which is costly.

Typically types: C1020, C1100 C2100, 2200, 2300, 2400, C2600 and above for red copper (purple copper), T2-Y purple copper plate

Hardness: C1020P-O (O on behalf of the soft material, no hardness), C1020P-1/2H (Vickers hardness HV75 ~ 120) 1/4H HV = 60 ~ 100 H HV = 80 or more HV

Thickness: 0.3mm or more (tolerance 0/-0.08)

Length and width: 610mm*1524mm

Features:

1. Cooper, excellent electrical and thermal conductivity, good processability, good fusion, corrosion resistance, weather ability, metallic red luster, suitable for the electrical and chemical industry

2. Brass, ductility, processability, and plating are often used for wiring equipment, instrument panels, bullet casings, etc.

How to Make the Right Choice

1. In order to facilitate the management and ensure the same quality of sheet metal parts in the same batch, the same product should minimize the type of raw materials and sheet thickness specifications to achieve one-time purchase of the same product in the same batch.

2. Select different materials according to the requirements of different parts. Such as the appearance or quality of parts with high requirements, it is recommended to choose stainless steel plate and aluminum plate, with good heat resistance and corrosion resistance.

3. Cost considerations. Under the circumstance of ensuring that the raw materials can meet the quality and mechanical properties of sheet metal parts, the cost of raw materials should be reduced as much as possible.

4. The thickness of the sheet metal parts should be best controlled between 0.5mm~2.5mm, 0.5mm thick cold rolled steel plate is not easy to control the size after welding and bending, and the processing difficulty of cold rolled steel plate over 2.5mm will be more difficult.

5. If the sheet metal parts need to be welded, powder coating can be used; if the parts do not need to be welded or welded parts are less, you can choose to use electrolytic galvanized steel, which not only shortens the processing cycle, but also facilitates the lower cost.

Common Materials Performance & Application

Only representative materials are listed, consult customer service for details.

Name |

Model |

Physical Properties |

Surface treatment |

Application |

|---|---|---|---|---|

| Stainless Steel | SUS304 | excellent corrosion and heat resistance | Mirror Polished; Brushed; Deburred | Tableware, cabinets, indoor plumbing, water heaters, boilers, microwave ovens, etc. |

| SUS301 | Springs, EMI, terminals, etc. | |||

| Cold Rolled Steel | SPCC | Good tensile strength and hardness, good elasticity. | Powder Coating; Painting; Galvanizing | Mounting brackets, wall mounting brackets, enclosures, wireless gateways, signaling devices, etc. |

| Aluminum | AL6061-T6 | Easily scratched, rusted and oxidized | Anodizing; Mirror Polishing; Brushing; Deburring Sandblasting Conductive Oxygenation | Automation components, electrical components, cans, lids, bottles, drums, packaging foils, etc. |

| AL5052-H32 | ||||

| AL1050 | ||||

| Galvanized steel | SGCC | excellent corrosion and oxidation resistance | Deburring | Small Appliances |

| SECC | Household appliances, computer cases, some doors and panels | |||

| Hot Rolled Steel | SPHC | Excellent weldability and hardness | Deburring | Ships, automobiles, bridges, construction, machinery, and pressure vessels |

| copper | C1020 | very high thermal conductivity and corrosion resistance; excellent weldability | Tin plating; Nickel plating; Passivation | Electronic connectors, leadframes, relay springs, switch contacts, precision electronic connectors, terminals |

| C1100 | ||||

| C2100 | ||||

| 329 / Cu- PHC R360 |

Reference

Standard and other

The ISO 2768 standard is the most common standard for sheet metal fabrication. It covers tolerance requirements for many industries, while balancing costs and processing capabilities.

Other

Materials are an essential basic capability in the industry, and their development can promote technology and innovation and society’s development. The current trend of material development is to be more environmentally friendly and energy-saving.

Related Blog

Automotive Die Casting and Casting Aluminum Alloys

Aluminum alloy has a series of excellent performance and highly efficient energy saving and environm…

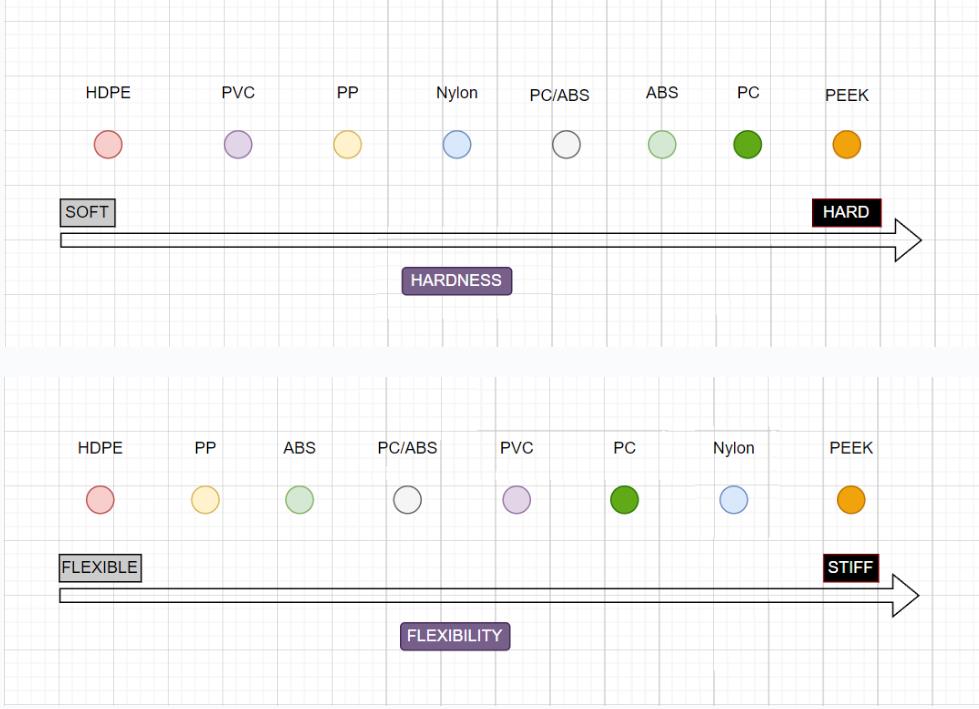

12 Design tips for plastic injection parts

Choose the right material Choosing the right plastic material for injection molded parts can be tric…

Plastic Injection Molding Materials

Table of Contents Features And Differences Among Materials Crystalline plastics Non-crystalline plas…

“Customers are our partners, so we prioritize their needs.”

— CapableMaching