Blog

More to learn about rapid prototyping and manufacturing industry.

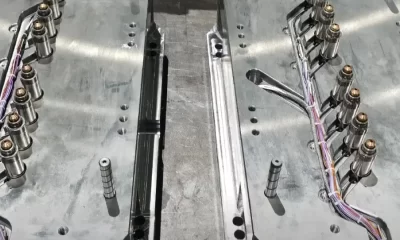

How to design a reverse hot runner injection mold design?

In recent years, with the booming development of the injection molding industry, a variety of plastic electronic products have become…

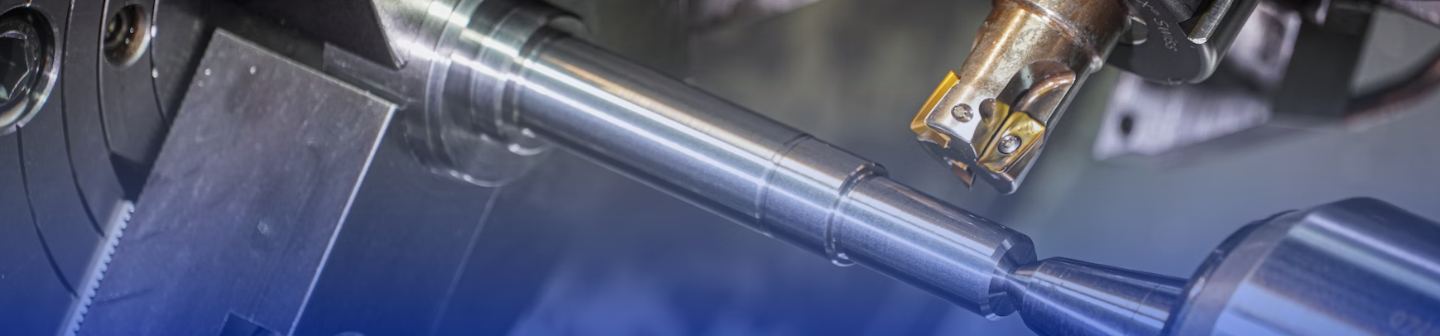

How does the 5-axis CNC perform machining?

Five-axis linkage CNC machining technology did not appear before parts processing. A three-axis machine tool was used in the past.…

How are CNC machine tools classified?

CNC machine tools have evolved dramatically since their invention. By now, its varieties and specifications are many and classified in…

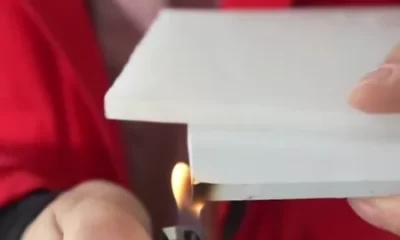

How to Quickly Estimate the Type of Plastic?

The invention of plastic dates back to the mid-1800s. The earliest plastic was celluloid, invented in England in 1856 by…

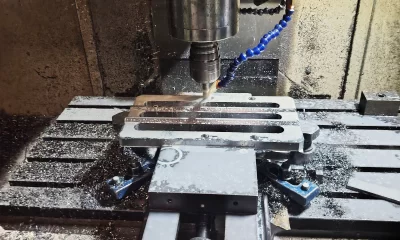

How to deal with overcutting and undercutting in CNC machine tool processing?

CNC machine tools have become an essential development in the field of machining. They are widely used in modern machining…

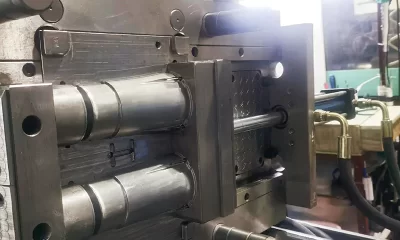

How to design a circular arc core pulling injection mold?

In the plastic shell mold design session, it often faces the challenge of various circular arc-type designs, which undoubtedly increases…

What are the mold materials in China?

Mold is the leading process equipment for industrial production, indispensable for all industries, and the mold industry is essential. Mold…

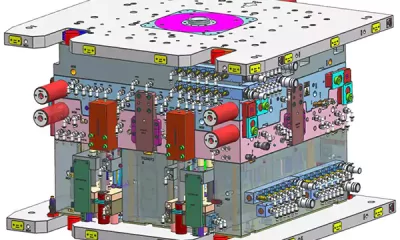

Mold Design Case: UAV Camera Lens Cover Mold Flow Analysis and Injection Mold Design

The increasing functions and types of UAVs have placed more demands on the design and manufacturing methods of various parts…

What is a U-drill?

The U-drill is a widely used indexable tool for hole machining in the mechanical industry. It drills holes with a…

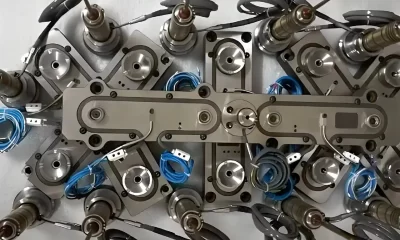

What Is Hot Runner Technology in Injection Mold?

As the plastic manufacturing industry grows, people demand better plastic products. Injection molds play a key role in plastic molding,…

What metallic materials are used in aerospace applications?

Since the Wright Brothers invented the airplane in 1903, the renewal of aircraft materials has shown a high rate of…

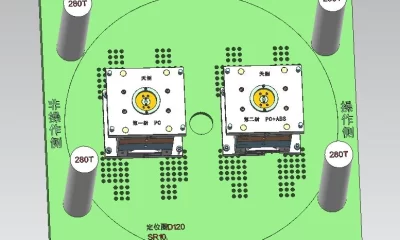

How to design a two-color mold?

Two-color plastic parts, because of their beautiful appearance, stable performance, and high bonding strength, are increasingly favored by people; two-color…