CNC Milling Advantages and Disadvantages

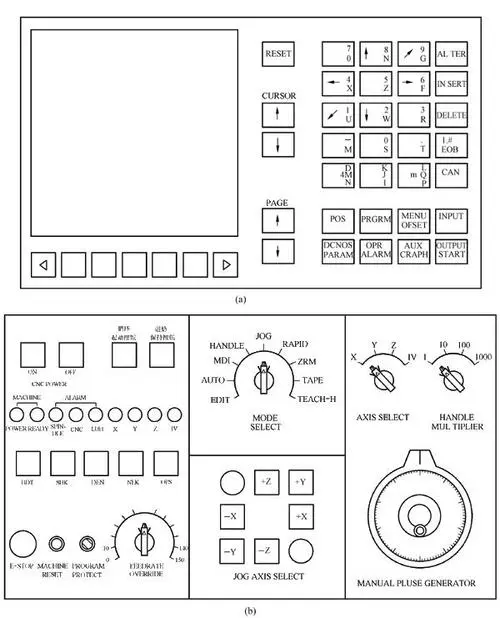

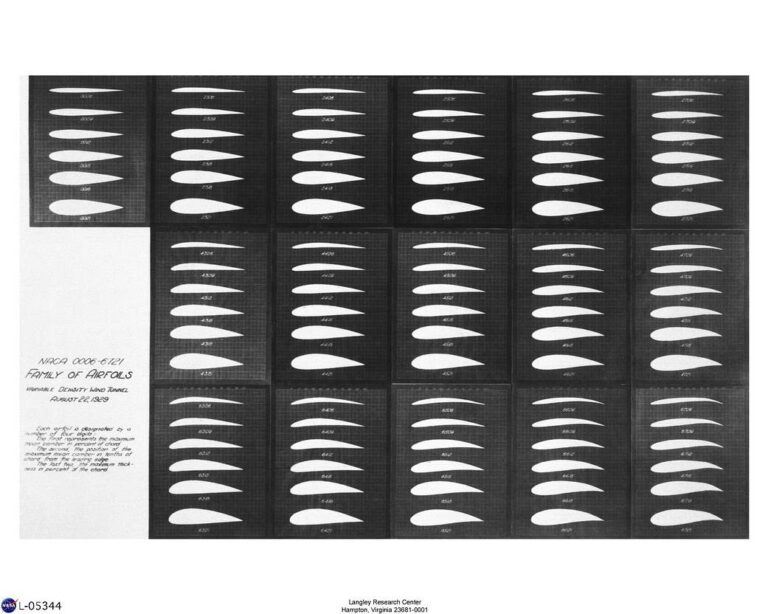

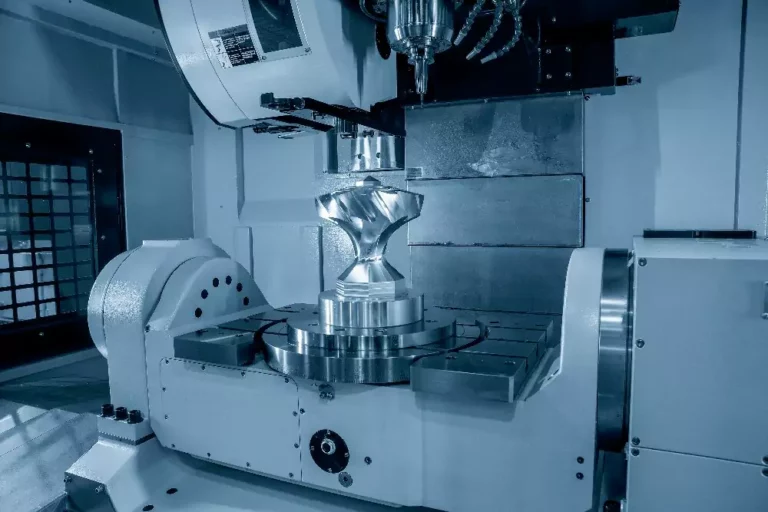

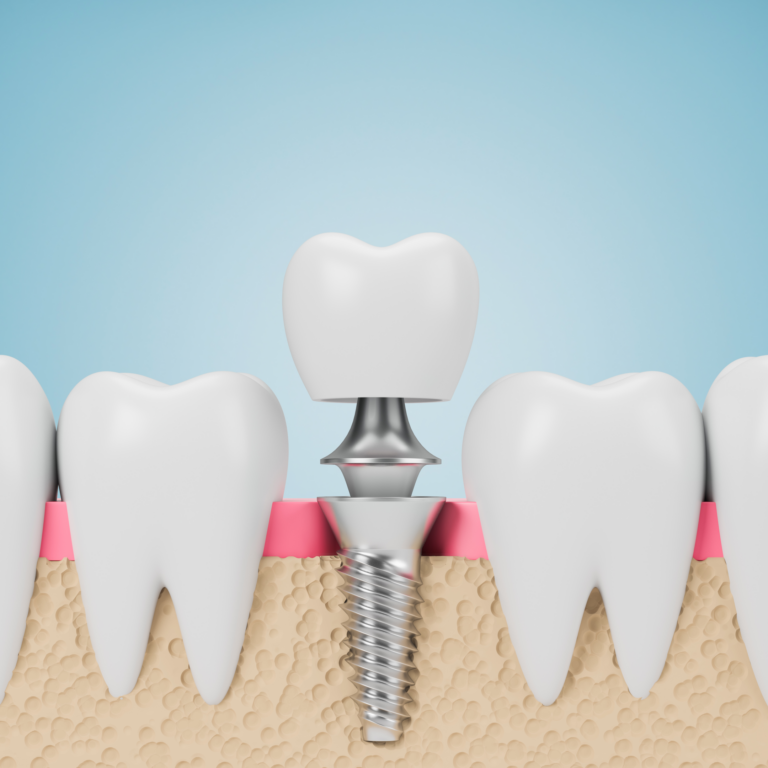

CNC machining offers a multitude of fabrication and milling capabilities, making it a prevalent choice in diverse manufacturing industries. The versatility of CNC machining processes and milling makes it highly valuable for creating prototypes, fabricating mechanical components, and other applications.…