How to Calculate CNC Machining Cost

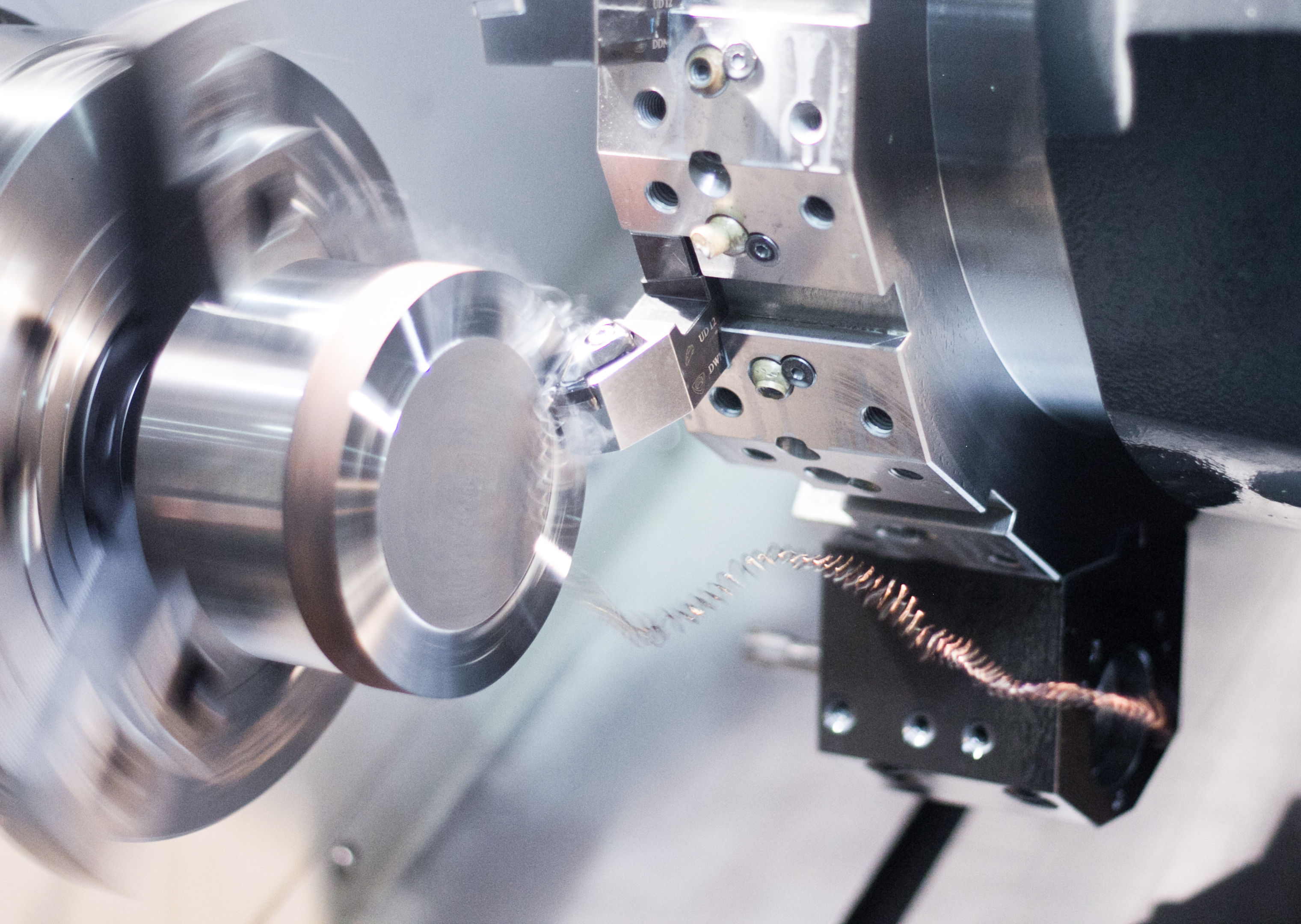

CNC machining stands as a groundbreaking and intricate subtractive manufacturing technique, where a metal or engineering plastic raw material undergoes a transformation into intricate components. The demand for CNC-machined parts remains exceptionally high across various industries, including aerospace, medical, automotive, consumer products, and robotics.

How does CNC machining work?

When the CNC system is activated, the software is programmed with the desired cuts, which are then executed by the corresponding tools and machinery, functioning akin to a robot.

In CNC programming, the code generator within the numerical system typically assumes the flawless operation of mechanisms, despite the possibility of errors, especially when the CNC machine is instructed to perform simultaneous cuts in multiple directions. The positioning of a tool in a numerical control system is defined by a sequence of inputs known as the part program.

In practice, there is much more to consider. Hardened materials need a stronger CNC machine, and more expensive cutting tools, resulting in a higher cost. Larger materials involve a higher risk of failure, resulting in a higher quote. Too thin wall thickness or too narrow cuts need extra care when machining, resulting in a higher cost too. There are many more factors to consider when the cost is calculated.

Factors Influencing CNC Cost

Part Complexity

Part complexity is a significant factor that greatly influences the pricing of CNC machining services. Machining complex parts tends to be more expensive because the cost is directly proportional to the intricacy of the design. The more complex a part is, the longer it takes to set up the CNC machine and the longer it takes to make the CNC program right, and the higher rate of failure too, all these translate into higher costs. It’s important to consider various elements that contribute to the overall cost, such as setup time, the number of setups required, programming time, and machining time, as these factors accumulate quickly.

To mitigate costs associated with part complexity, it is advisable to incorporate Design for Manufacturability (DFM) principles. When designing parts for CNC machining, it is best to consider the chosen manufacturing techniques and capabilities. Basic DFM for CNC machining includes avoiding thin walls, avoiding sharp corners, avoiding narrow areas, using complex curve faces only necessary, and trying to integrate features into rather fewer sides (reduce the chance of multi-axis machining).

Although sometimes using a 5-axis machine instead of a 3-axis machine can enhance efficiency, a 5-axis machine’s depreciation cost per hour is substantially higher than a 3-axis one, so is the salary for the programmer who can handle the more complicated 5-axis programming. In general, we should always avoid using the 5-axis whenever possible. Limiting the CNC machining process to a few faces of the part can also reduce complexity and associated costs. By integrating DFM feedback into the design process, it is possible to optimize manufacturing and minimize expenses.

Raw Material Selection

When calculating the cost of CNC machining, the selection of raw materials is another crucial aspect to consider. Typically, four common metals are often chosen for most CNC machining projects: titanium, steel, stainless steel, and aluminum. Each material option has its own cost implications and unique properties:

Titanium

Titanium is the most expensive option but offers an excellent strength-to-density ratio. It is a preferred choice for applications requiring high strength and low weight. Titanium has about half of the steel weight with the same strength. For CNC machining, this material is particularly hard to handle, not only because of its hardness but also its poor thermal conductivity. The heat generated during the machining of Titanium could easily accumulate around the cutting tool tip and cause failure. Those extra troubles make the Titanium machining higher cost.

Aluminum

Aluminum is relatively less expensive compared to titanium and provides a lightweight option with good strength characteristics. It is commonly used when weight reduction is a priority.

Steel

Steel is a cost-effective choice with a higher density compared to aluminum and titanium. It is known for its strength and durability, making it suitable for various applications. Obviously, it is easier to machine a steel part than a titanium part but harder than an aluminum part. So is the cost.

Stainless Steel

The cost of CNC machining stainless steel parts will vary greatly depending on the type of stainless steel. SUS 630, and SUS 316 are very hard to machine. SUS 304 is hard to machine too but not as bad as SUS630. SUS303 is much easy to deal with, it is easier to machine than most of the carbon steel. It surely costs more for CNC machining when materials are harder to machine.

And even for the same material, different hardening status makes different cost. It is important to note that selecting harder materials can increase the machining cost due to faster tool wear and the need for more frequent maintenance to maintain sharpness, which adds to the cost per piece.

It is also worth mentioning that modern superalloys possess exceptional strength and other desirable material properties, but they come with a higher price tag. Therefore, it is crucial to carefully consider material costs and choose the appropriate materials based on cost-effectiveness and specific project requirements.

Cost of Labour

Once the CNC machining process is set up, it operates with minimal human intervention. However, certain roles such as programmer, machinist, and engineer are still necessary for a successful operation. The following points highlight the importance of these roles and their impact on CNC machining costs:

Programming

A programmer is responsible for converting a Computer-Aided Design (CAD) file into a Computer-Aided Manufacturing (CAM) file. While advancements in AutoCAD technology enable automated toolpath programming, a programmer’s expertise may still be required for complex projects. The availability of automated programming options has reduced the reliance on human involvement for this step.

Machining

A skilled machinist plays a crucial role in setting up the CNC machines for production. This involves tasks such as cutting the billet, loading materials and overseeing the machining process. The cost of machining is influenced by factors like the number of parts produced and the complexity of the machining operations involved.

Quality Control and Post-processing

The cost of CNC machining also includes considerations for quality control and post-processing activities. Quality control measures ensure that the machined parts meet the specified requirements and standards. Additionally, post-processing steps such as surface finishing, deburring, and inspection may vary across different industries and can impact the overall cost.

Type of Equipment Required

The cost of CNC machining is impacted by various factors, including the specific equipment, tools, or machines employed in the production process. Modern machines can be quite expensive, with 5-axis machining centers being a prime example. These advanced machines offer a wide range of functions, making them suitable for producing complex parts.

In general, the complexity and capabilities of the equipment affect the cost per unit of time. Simplistic machines tend to be more cost-effective in terms of production expenses. For instance, ordinary CNC lathes are less expensive to operate compared to vertical CNC lathes, and milling machines are generally more affordable than CNC machining centers.

How to Calculate the Cost

Apart from knowing the factors that influence the cost, we still need to know how to calculate it. The total cost of CNC machining is divided into several parts:

Material Cost Calculation

Material cost calculation in CNC machining involves determining the cost of the raw materials required to produce the machined parts. The following steps outline the process:

Material Selection

Choose the appropriate raw material based on the specifications and requirements of the part, considering factors such as strength, durability, and chemical resistance.

Material Quantity

Determine the amount of material needed for each part, taking into account the dimensions, tolerances, and any potential wastage.

Material Cost per Unit

Determine the cost of the raw material per unit (e.g., per kilogram, per square meter, etc.). This cost can be obtained from suppliers or based on market prices.

Calculation of Material Cost

Multiply the material quantity by the cost per unit to calculate the total material cost for producing the part.

Tooling Cost Calculation

Tooling cost calculation in CNC machining involves determining the cost associated with the tools required for the machining process. The following steps outline the process:

Identification of Required Tools

Identify the specific tools needed for each machining operation, including end mills, drills, taps, reamers, inserts, and any specialized tools required for the part.

Tool Life Estimation

Determine the estimated tool life for each tool based on factors such as tool material, cutting conditions, and the material being machined. Tool life can be obtained from tool manufacturers’ recommendations or past experience.

Cost per Tool

Determine the cost of each tool based on the supplier’s prices or market rates.

Calculation of Tooling Cost

Multiply the cost per tool by the number of tools required for each operation, taking into account tool life and the number of tool replacements needed for the production run.

Labor Cost Calculation

Labor cost calculation in CNC machining cost calculation involves determining the cost associated with the human labor involved in the machining process. The following steps outline the process:

Determine Labor Rates

Obtain the hourly labor rates for the different roles involved in CNC machinings, such as programmers, machinists, and engineers. These rates can vary based on factors such as skill level, experience, and geographical location.

Estimate Labor Time

Analyze the machining process and estimate the time required for each labor task involved, including programming, setup, machining, quality control, and post-processing.

Calculate Labor Cost

Multiply the labor rates by the estimated labor time for each task to calculate the labor cost for that specific task.

Summarize Labor Costs

Sum up the labor costs for all tasks to obtain the total labor cost for the CNC machining process.

Overhead Cost Calculation

Overhead cost calculation in CNC machining involves determining the indirect costs associated with the overall operation of the machining facility. The following steps outline the process:

Identify Overhead Expenses

Identify the various overhead expenses incurred in the CNC machining facility. These expenses may include rent, utilities, insurance, maintenance and repairs, equipment depreciation, administrative costs, employee benefits, and other indirect costs.

Determine Cost Allocation Method

Select an appropriate cost allocation method to distribute the overhead expenses across the production activities. Common methods include direct labor hours, machine hours, or a percentage of direct labor costs. Choose the method that best reflects the relationship between the overhead costs and the production activities.

Gather Data

Collect the necessary data related to the chosen cost allocation method. This includes the number of labor hours or machine hours used, the direct labor costs, or any other relevant data required for allocating the overhead costs.

Calculate Overhead Rate

Divide the total overhead expenses by the appropriate allocation base (e.g., direct labor hours, machine hours, or direct labor costs) to calculate the overhead rate per unit of allocation.

Apply Overhead Rate

Multiply the overhead rate by the actual allocation base used in the production activities to determine the overhead cost allocated to each unit or job.

Summarize Overhead Costs

Sum up the allocated overhead costs for all units or jobs to obtain the total overhead cost for the CNC machining process.

Conclusion

In conclusion, calculating the cost of CNC machining involves considering various factors that contribute to the overall expenses. Key factors include part complexity, raw material selection, tooling cost, labor costs, and overhead expenses. By analyzing these factors and performing the necessary calculations, a more accurate estimation of the CNC machining cost can be obtained.

It is important to carefully assess each component and consider optimization strategies such as design for manufacturability (DFM) feedback and material selection to reduce costs without compromising quality. Additionally, regular review and adjustment of cost allocation methods and rates for overhead expenses help ensure accurate cost calculations. By thoroughly evaluating these elements, businesses can make informed decisions and effectively manage the costs associated with CNC machining processes.