The History of CNC Machines

- The First CNC Machine

- The Developing History of CNC Machines

- An important inflection point in the course of development

- The evolution of the development of key and core technologies of CNC machine tools

- Advances in Machining Efficiency and Accuracy

- Current Trends and Future Outlook:

- Building on Rapid Prototyping

- Advantages of CNC Machines

- Embrace Today’s CNC Technology

CNC literally means computer numerical control. In a broad sense, any computer numerically controlled machine can be called a CNC machine. Such as CNC punching machines, CNC laser cutting machines,s and so on. This article is about the history of CNC milling machines, or machining centers. In the processing industry, there is no specific type of machine tool. When only CNC is mentioned, it refers to CNC milling machines (machining centers).

Before the emergence of the CNC machine, as early as the 15th century has appeared early machine tools, 1774 British John Wilkinson invented a kind of gun barrel boring machine that is considered to be the world’s first real sense of the machine tool, which solved the watt steam engine cylinder processing problems. In the 18th century, various types of machine tools appeared one after another, and rapid development, such as threaded lathes, gantry machine tools, horizontal milling machines, hobbing machines, etc., for the Industrial Revolution and the establishment of modern industry, laid the foundation for manufacturing tools.

The First CNC Machine

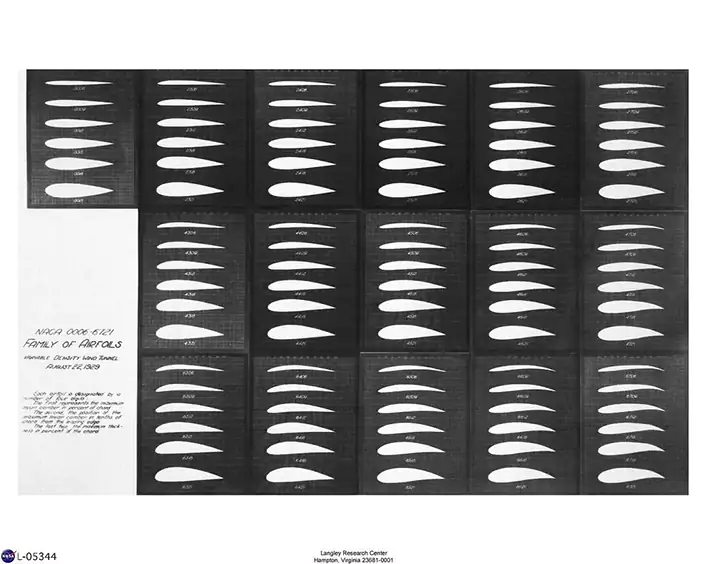

The origin of the matter is how to machine the airfoil curve. Different airfoil curves will exhibit different lift, drag, stall angles, etc. at various airspeeds. Machining blades or airplane wings with specific airfoil curves and shapes was a big challenge. Making such complicated parts with a manual milling machine is laborious and imprecise.

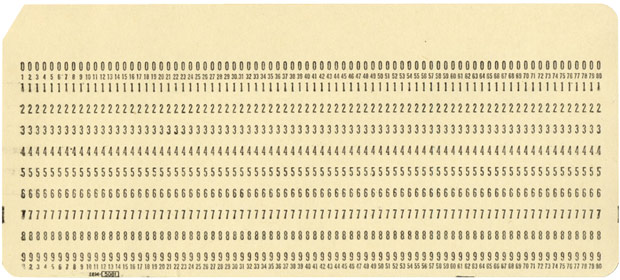

The story begins with John T. Parsons, an engineer and inventor, who is credited with pioneering the concept of numerical control. In 1949, Parsons, along with his employee Frank Stulen, developed a system that utilized punched cards to control the movements of machine tools. This system laid the foundation for what would later become known as computer numerical control (CNC).

Punched cards

On the other hand, the punched card was first invented in 1725 by Basile Bouchon, a French weaver, who invented a method of controlling a loom through a series of punched holes using data encoded on a paper tape. Although groundbreaking, the method was fragile and still required an operator. In 1805, Joseph Marie Jacquard adopted the concept but enhanced and simplified it by punching more robust cards in a sequence to automate the process.

MIT, the Massachusetts Institute of Technology, played a significant role in the story. Parsons, who was an alumnus of MIT, collaborated with the university’s Servomechanisms Laboratory to further develop and refine his numerical control system. Together, they conducted research and experiments to improve the capabilities and functionality of NC machines.

With the support and expertise from MIT, Parsons continued to refine his numerical control system, making significant advancements in the field. The partnership between Parsons and MIT led to the establishment of the first commercial NC machine tool company, the Parsons Corporation.

The NC (numerical control) machine at that time is not a CNC (computer numerical control) machine yet. The computing systems in the 1940s and 1950s used punched cards as a primary input method. Operators would create programs and data on punched cards, which were then fed into the computer for processing. That is why the “auto” machine at that time is called “NC” not “CNC”. In the late 1950s and early 1960s, keyboards and screens, also known as consoles or terminals, began to replace punched cards for certain tasks.

The term “CNC” itself became more commonly used in the 1970s when computer technology and miniaturization advanced to a level that allowed for the integration of computers directly into machine tools. This integration marked a significant milestone in the history of CNC machines, leading to their widespread adoption and revolutionizing the manufacturing industry.

The Developing History of CNC Machines

Early Developments (1940s-1950s):

The concept of Numerical Control (NC) took shape in 1949 when John T. Parsons, an early computing pioneer, developed it during an Air Force research project at MIT. The project aimed to create motorized axes for manufacturing helicopter blades and aircraft skins.

Parsons Corporation in Traverse City, Michigan, preceded the MIT collaboration by using an IBM 602A multiplier to calculate airfoil coordinates. The data was then fed into a Swiss jig borer using punched cards. This marked the early stages of CNC machine programming.

In 1952, Richard Kegg, in collaboration with MIT, introduced the Cincinnati Hydro-Tel, a vertical-spindle contour milling machine. It was commercially launched with a patent for a “Motor Controlled Apparatus with Positioning Machine Tool.” The initial prototype used eight-column paper tape, a tape reader, and a vacuum-tube electronic control system, setting the stage for future advancements.

During the 1940s and 1950s, early CNC machines utilized punched tape, a technology commonly used in telecommunications and data storage. This was later replaced by analog computing technologies. In the 1960s and 1970s, digital technologies emerged, leading to automated and more efficient production processes.

Parsons received recognition for his early contributions. In 1968, he was honored with the first Joseph Marie Jacquard Memorial Award from the Numerical Control Society. The Society of Manufacturing Engineers also presented him with an honorary plaque in 1975, naming him “The Father of the Second Industrial Revolution.”

Pioneering CNC Technology (1950s-1960s):

In the 1950s, the Massachusetts Institute of Technology (MIT) pioneered further advancements in numerical control technology. John T. Parsons, together with MIT engineer Frank L. Stulen, developed the concept of “numerically controlled milling” and built the first milling machine controlled by data stored on a punched card.

CNC Emerges (1960s-1970s):

Today, thanks to electronic control, such scenarios are highly improbable, and the outcomes of CNC machining are more predictable. CNC machines have the versatility to work with various materials, including metals, wood, plastics, fiberglass, and foam.

Furthermore, innovative machining techniques have been developed based on the principles of CNC machining. These methods include Electron Beam Machining, Electrical Discharge Machining, and Photochemical Machining. The choice of technique often depends on the material used in the mass-production process. Additionally, laser, oxy-fuel, water-jet, and plasma-cutting machines have become common in the industry.

Industry Adoption (1980s-1990s):

In the 1980s and 1990s, CNC technology gained widespread acceptance in the manufacturing industry. The development of microprocessors, improved software, and increased affordability of computers made CNC machines more accessible to smaller businesses. CNC machines began replacing traditional manual and mechanically automated machines, offering enhanced accuracy, repeatability, and flexibility.

Advancements in Automation (2000s-2010s):

The 21st century brought further advancements in CNC technology. Machining centers, lathes, and other CNC machines became increasingly integrated with robotic systems for enhanced automation. This integration allowed for lights-out manufacturing, where machines could run unattended for extended periods, increasing productivity and reducing labor costs.

An important inflection point in the course of development

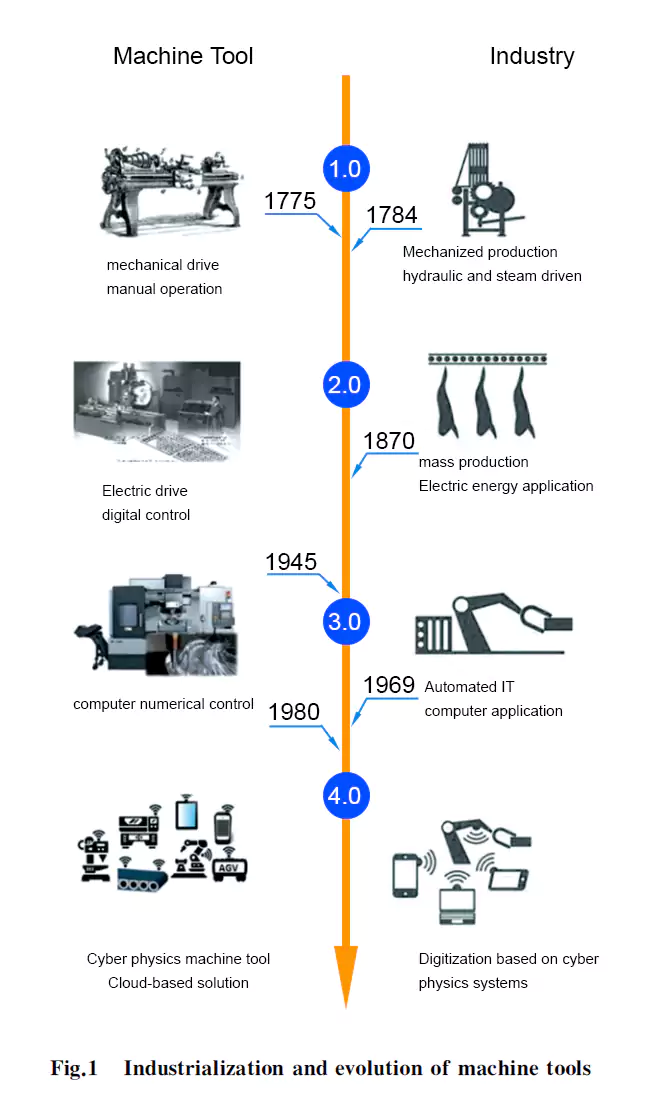

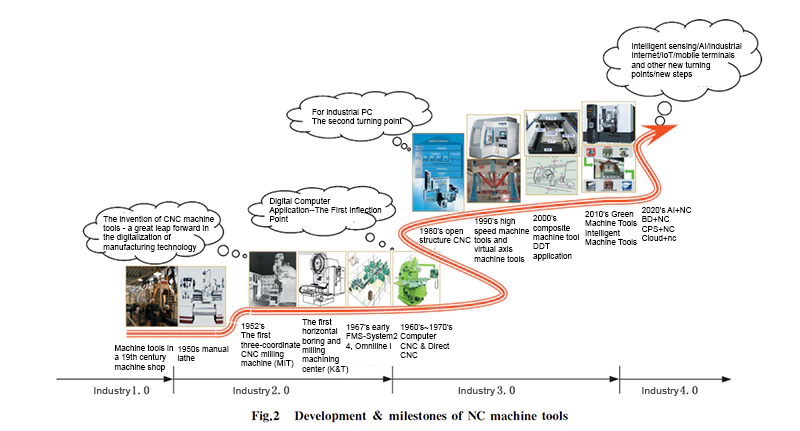

Let us look back at the magic process, it is because of CNC machine tools and CNC technology at the beginning of the birth of several major features – digital control ideas and methods, “software and hardware” combination, “Mechanical, electrical, and control information” multidisciplinary intersection, and therefore the subsequent major advances in CNC machine tools and CNC technology has been directly related to the development of electronic technology and information technology (Figure 2).

The earliest numerical control device is the use of electronic vacuum tubes constituted a computing unit, In the 20th century, at the end of the 40’s crystal tube was invented, the end of the 50’s introduced integrated circuits, to the early 60’s the emergence of the use of integrated circuits and large-scale integrated circuits of electronic digital computers, computers in the arithmetic processing power, miniaturization and reliability of breakthroughs in the development of numerical control machine tools for the development of the first inflection point — digital control (NC) based on discrete components to the computer numerical control (CNC), CNC machine tools have begun to enter the actual industrial production applications.

In the 1980s, IBM launched a personal microcomputer (personal computer, PC) with a 16-bit microprocessor, which brought the second inflection point to the CNC machine tool technology — from the past to the development of special-purpose manufacturers of CNC devices (including hardware and software) to the use of general-purpose PC-based computers. Toward the use of universal PC-based computer numerical control, at the same time the open structure of the CNC system was born, promoting CNC technology to a higher level of digitalization, network development, high-speed machine tools, virtual axis machine tools, composite processing machine tools, and other new technologies, rapid iteration, and application.

Since the 21st century, intelligent CNC technology has also begun to sprout, currently with the development of a new generation of information technology and a new generation of artificial intelligence technology, intelligent sensing, Internet of Things, big data, digital twins, cyber-physical systems, cloud computing and artificial intelligence and other new technologies with the depth of the combination of numerical control technology, CNC technology will usher in a new inflection point or even may be a new leap — towards the cyber-physical fusion of the new technology. –Toward cyber-physical fusion of a new generation of intelligent CNC [4].

The evolution of the development of key and core technologies of CNC machine tools

1. Structure of CNC machine tools

Machine tool structure mainly includes two major parts: the fixed parts of the machine tool (such as the base, bed, column, headstock, etc.), and the moving part that carries the workpiece and tool, which are now commonly known as the basic parts and functional parts of the machine tool.

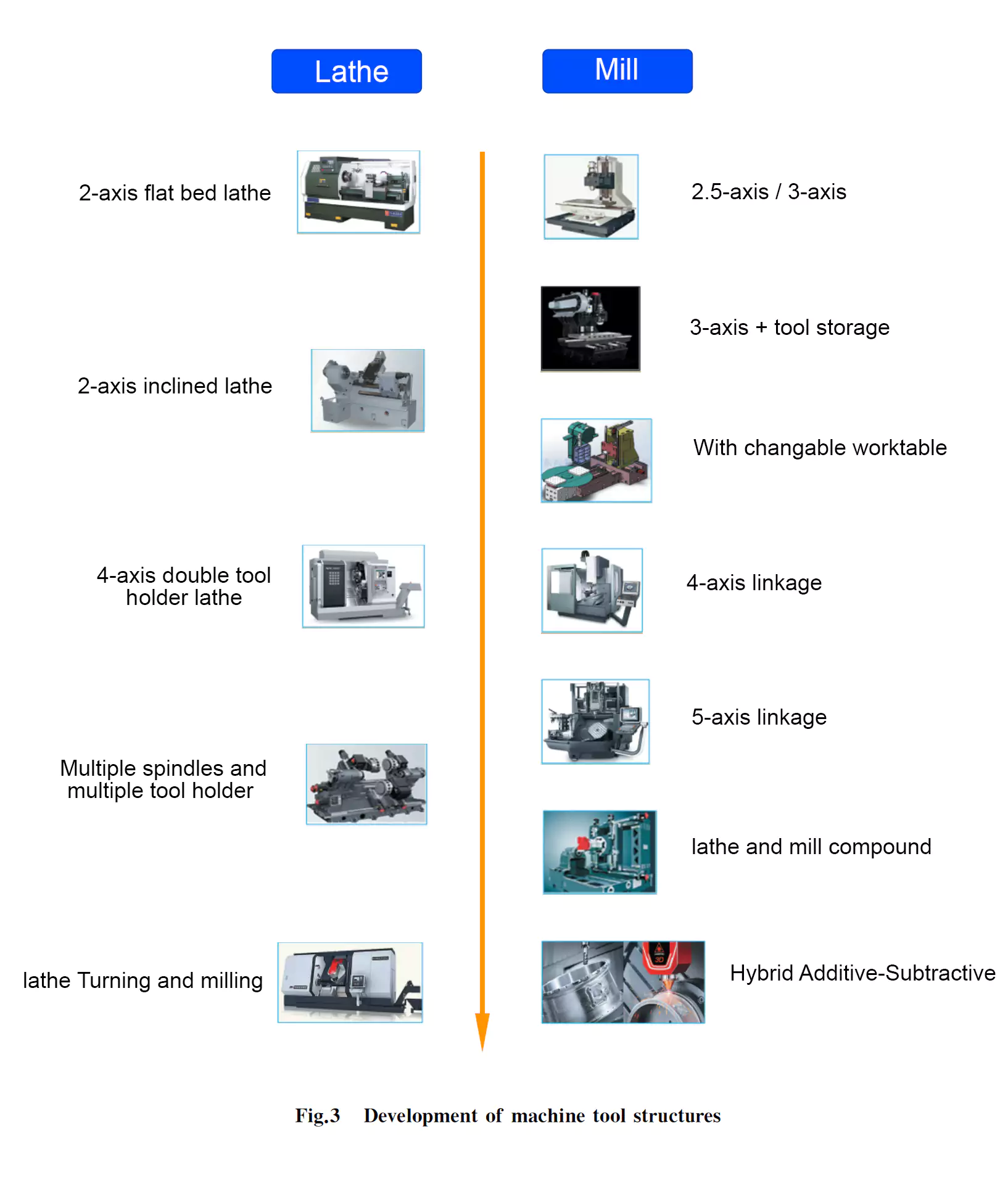

Taking common turning and milling as an example, the evolution of a typical CNC machine tool structure is shown in Figure 3.

CNC turning machine structure from the early 2-axis feed flat bed, 2-axis feed slant bed, and other classic structures, to 4-axis feed and double tool holder, multi-spindle and multi-tool holder for rotary parts such as high-efficiency turning machining center structure, and further development of complex parts to adapt to the “a clamping, all complete (doneinone)” multifunctional turning and milling compound machine. “Multi-functional turning and milling compound processing center structure.

CNC milling machine structure from the early mainly realized coordinate axis linkage and spindle movement function of the classic vertical/horizontal milling machine structure, the development of 3-axis linkage vertical/horizontal milling machining center structure with tool magazine and automatic tool changer, with the exchange of the worktable of the vertical/horizontal milling machining center structure, to meet the demand for high-efficiency machining of complex structural parts, and the emergence of 4-axis linkage and 5-axis linkage milling machining center structure, followed by the milling / boring machining center structure to meet the complex parts “once clamped, all finished (oneinone)” multi-functional turning and milling complex machining center structure. To meet the demand for high-efficiency machining of complex structural parts, 4-axis and 5-axis milling machining centers have emerged, and then the multifunctional milling/turning machining center structure with milling/boring as the main function and turning/drilling function has been rapidly developed and applied.

In the development process of 5-axis linkage, the concept of a parallel virtual axis from the robot was introduced to the CNC machine tool, the emergence of parallel or series-parallel combination of 5-axis linkage form, but the practical application is limited. At present, in the same CNC machine tool to achieve the “additive machining + cutting machining” function of adding and subtracting materials mixed processing (hybrid additive-subtractive manufacturing) new structure of the machine tool has entered the practical development stage.

In the evolution of the CNC machine tool structure development process, CNC machine tool structure layout (configuration plan, optimization design) material selection, and other aspects of the technology have also continued to progress.

To meet the requirements of high precision, high stiffness, good thermal stability, long life and high precision retention, green and pleasant to the machine structure, researchers have put forward the center of gravity drive (drive at the center of gravity, DCG) design, box in the box (BIB), direct drive (IB), direct drive technology(DDT), thermal balance design and compensation, fully symmetrical structural design and other design principles and technologies; in machine tool structural design and optimization of the overall structure of parts and components finite element analysis optimization, lightweight design, structural topology optimization, bionic structure optimization and other methods;

Adopting the concept and method of virtual machine tools greatly shortens the design and manufacturing cycle of CNC machine tools. The bed structure material of CNC machine tools has developed from cast iron and cast steel to more and more resin concrete (mineral casting, artificial marble), artificial granite, and other materials. In addition, steel fiber concrete, carbon fiber composite materials, foam metal, and other new structural materials have also been applied.

In the future, new materials, new optimized structures, and new manufacturing process methods will make the structure of CNC machine tools more lightweight and have better static and dynamic stiffness and stability.

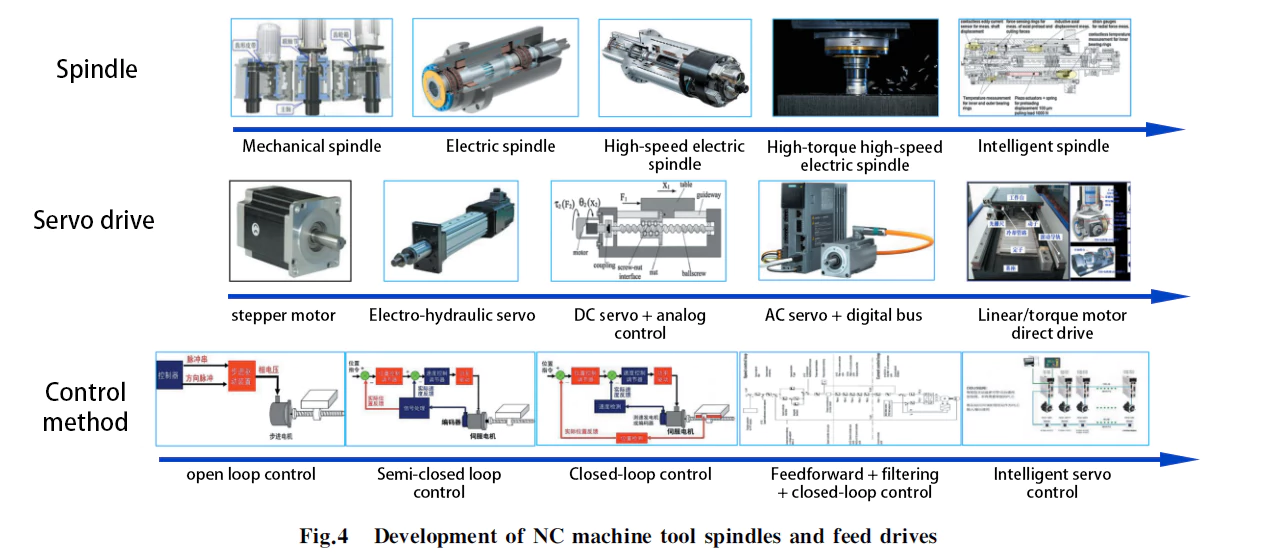

2. Spindle and feed servo drive technology

The role of the spindle is to drive the cutter tool or grinding tool (drilling/milling/grinding) or workpiece (turning) at a given speed rotation and transfer the power and torque required for cutting and processing so that the cutter (grinding) tool on the workpiece to achieve material removal. The development process of the CNC machine tool spindle appears non-speed-regulated AC motor through the spindle box drive mechanical spindle, motor and spindle integration of the spindle, high-speed spindle, high rigidity and high torque high-speed spindle and intelligent spindle, and so on.

Machine tool feed axis servo drive from stepper motors, electro-hydraulic proportional servo, thyristor current converter and PWM control of DC motor servo and other forms of development to now become the mainstream vector control AC motor servo, the dual motor center of gravity drive (DCG), linear motor/torque motor direct drive and other forms of development, but also more adopts with the position loop, speed loop, current loop and “feed-forward + filtering” the full closed-loop control to provide motion control with high speed, high accuracy and high dynamic response for each axis.

In addition, the servo control mode from analog control, through the “analog + digital” hybrid control mode, the development of all-digital field industrial bus control mode, such as serial real-time communication protocol(SERCOS)bus and real-time Ethernet control automation technology(Ether CAT) bus, process field bus( PROFIBUS), and so on.

The development of NC machine tool spindle sand feed drives is shown in Figure 4.

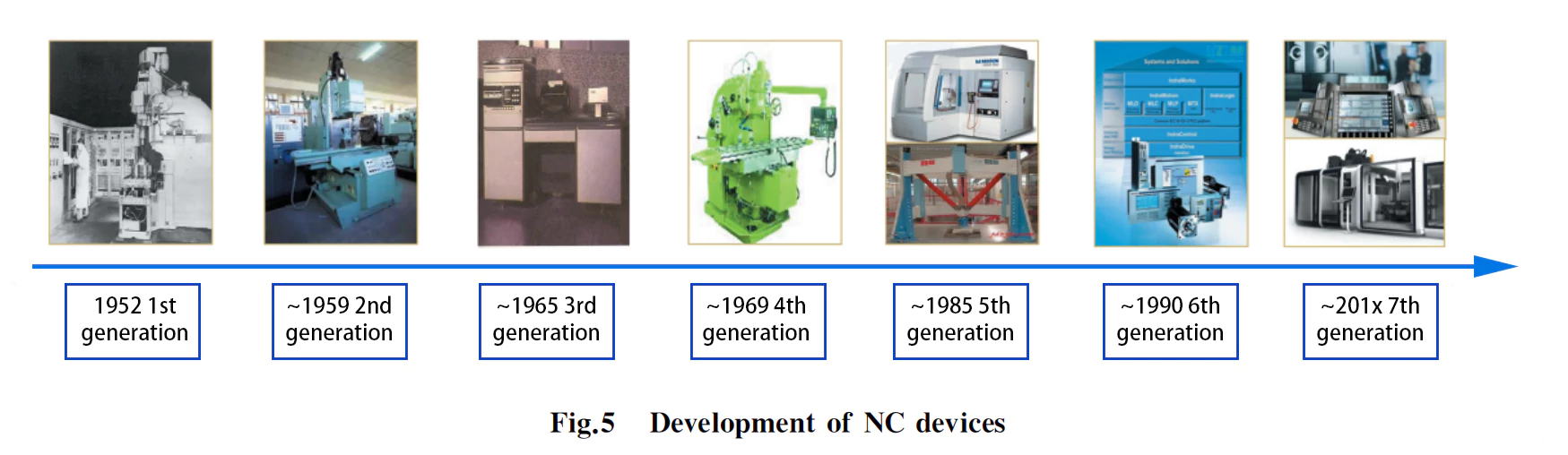

3. Numerical control device

CNC device is the hub of CNC machine tool control, as mentioned earlier, the CNC device follows closely the development of electronic technology, computer technology, and information technology. Its development process can be divided into 7 generations (Figure 5), the 1st, 2nd, 3rd generations use of tube discrete components, transistors, and integrated circuits, respectively, in the early stages of development of CNC device, volume and power consumption, low reliability, poor practicality.

Generation 4 for the use of small electronic digital computer CNC devices, compared to previous generations, its hardware platform is compact, specialization, and reliability have improved greatly, CNC technology into the computer numerical control of the new track, so that the CNC machine tools enter the practical stage and accelerate the iteration and development, which is the first inflection point for the development of CNC machine tools, direct numerical control (DNC), flexible manufacturing system (FMS) and other concepts and systems have emerged.

With the maturity of ultra-large-scale integrated circuit micro central processor technology, the 5th generation of CNC devices will be based on microprocessor hardware or single-board computers used as its hardware platform, further reducing the hardware volume and cost. Still, the compatibility and openness of its hardware structure is poor.

In the 1980s, personal microcomputers (PCs) were adopted in the 6th generation of CNCs, bringing the second inflection point in the development of CNC machines.

Taking advantage of the PC’s mature software/hardware platform, rich application resources, and common networked interfaces, the research and development of numerical control devices shifted to software algorithms to realize various functions, i.e., entering the open, networked, and software-enabled numerical control stage.

With the development of Industry 4.0, the 7th generation of intelligent CNC devices and intelligent machine tools integrating intelligent sensing, Internet of Things/Industrial Internet, Big Data, Cloud Computing, Artificial Intelligence, Digital Twin, and Cyber-Physical Systems are coming to us, which will bring a new inflection point to the development of CNC technology, and may even bring a new revolution.

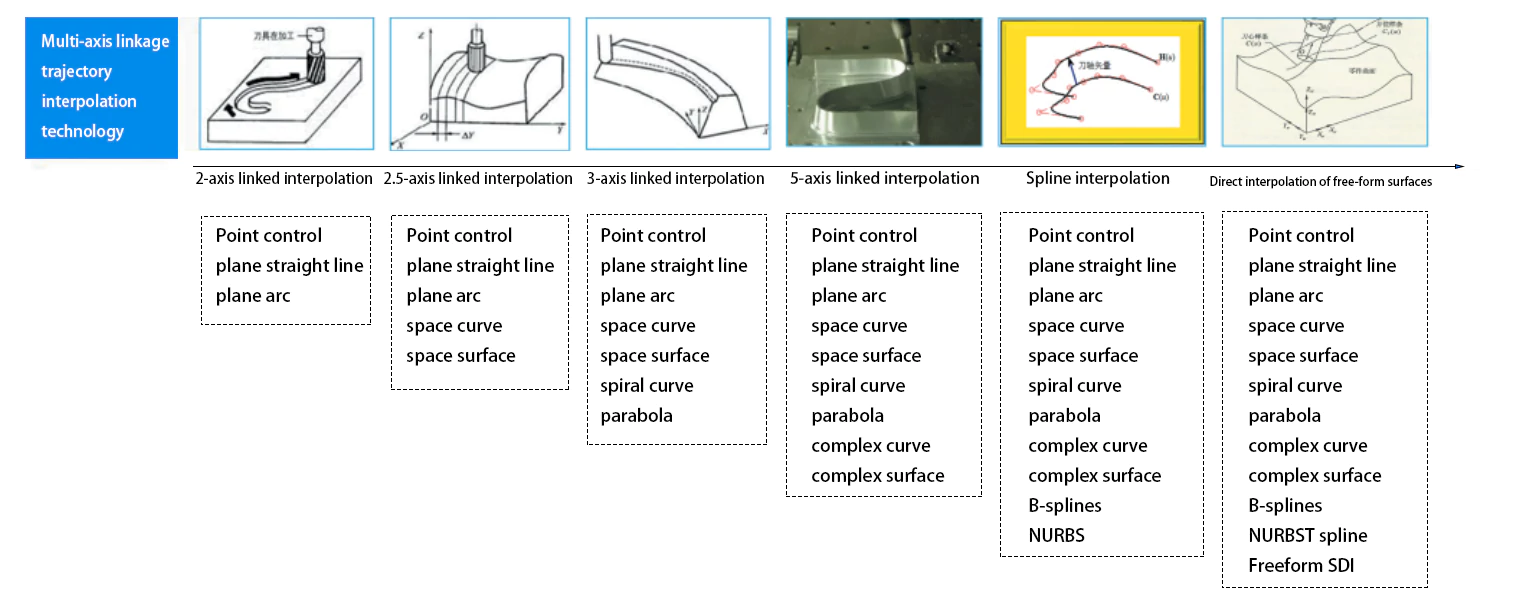

4. Multi-axis linkage and track interpolation technology

Multi-axis linkage control technology is one of the core technologies of CNC machine tool control. CNC machine tool feed axis (including linear coordinate feed axis and rotary coordinate feed axis) under the control of the CNC device following the program instructions at the same time movement is called multi-axis linkage control.

High-grade CNC machine tools generally have a 3-axis or more than 3-axis linkage control function, mostly 4-axis linkage or 5-axis linkage. The movement of each feed axis is generally realized by the motor under the control of the servo drive.

Therefore, high-performance axis feed servo devices constitute the physical basis for the realization of multi-axis linkage control. Multi-axis linkage control is based on the CNC machining program to give the trajectory (i.e., tool path), through the trajectory interpolation and real-time control, in each servo control cycle to give the linkage axis of the operation of the incremental, real-time control of the linkage of all the coordinate axes.

Trajectory interpolation is also one of the core technologies of CNC machine tool control. Realization of interpolation computing device (or software module) called interpolator, modern CNC machine tools generally use digital computers through software to achieve trajectory interpolation. The development process of trajectory interpolation technology is shown in Figure 6.

From the perspective of the realized interpolation function, the 2-axis linkage of plane point control, plane straight line, and arc interpolation is the simplest interpolation function;

2.5-axis linkage interpolation has only 2-axis linkage control, and its third axis can only realize non-linkage control with the other 2 axes, so the linkage interpolation can process 3D curves and curved surfaces, but the efficiency is low and the adaptability is poor;

3-axis linkage interpolation in addition to the realization of plane and space linear interpolation, arc interpolation function, high-grade CNC system also has a spiral interpolation, parabolic interpolation, and other functions;

5-axis linkage interpolation can be efficient and convenient to achieve a variety of complex curves and surfaces interpolation functions, and further development of spline interpolation and advanced speed, acceleration, rate of change of acceleration (Jerk), and other control functions, is the core technology of high-speed, high-precision, high-dynamic response to the core technology of processing.

The author believes that future CNC devices will also develop free surface direct interpolation function (SDI), and is expected to be combined with the toolpath planning based on artificial intelligence and digital twin, in consideration of the multi-axis linkage dynamics model as well as the trajectory error and speed constraints, to achieve the toolpath generation and optimal control of multi-axis linkage multi-axis direct machining, which is driven by the 3D model. Optimally controlled direct interpolation of the multi-axis linkage.

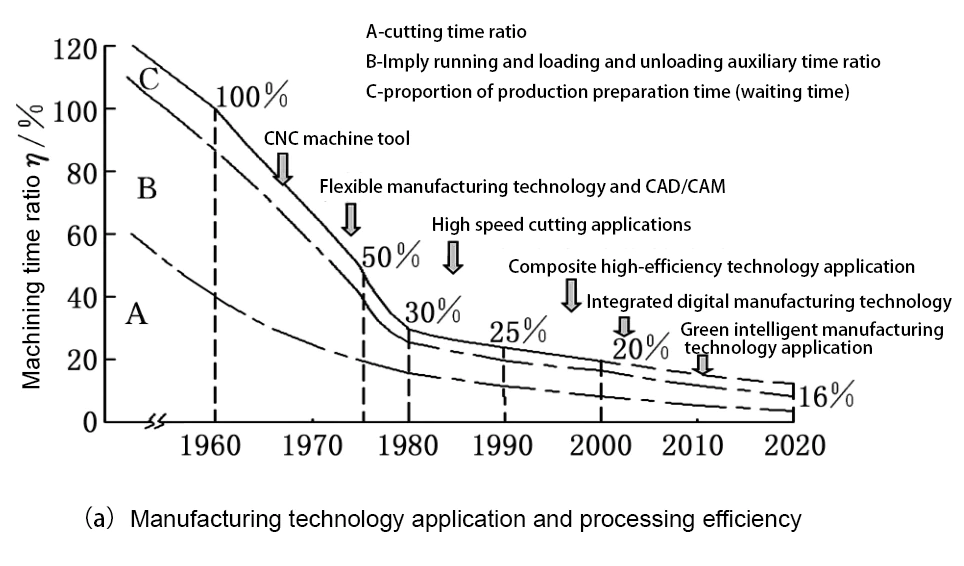

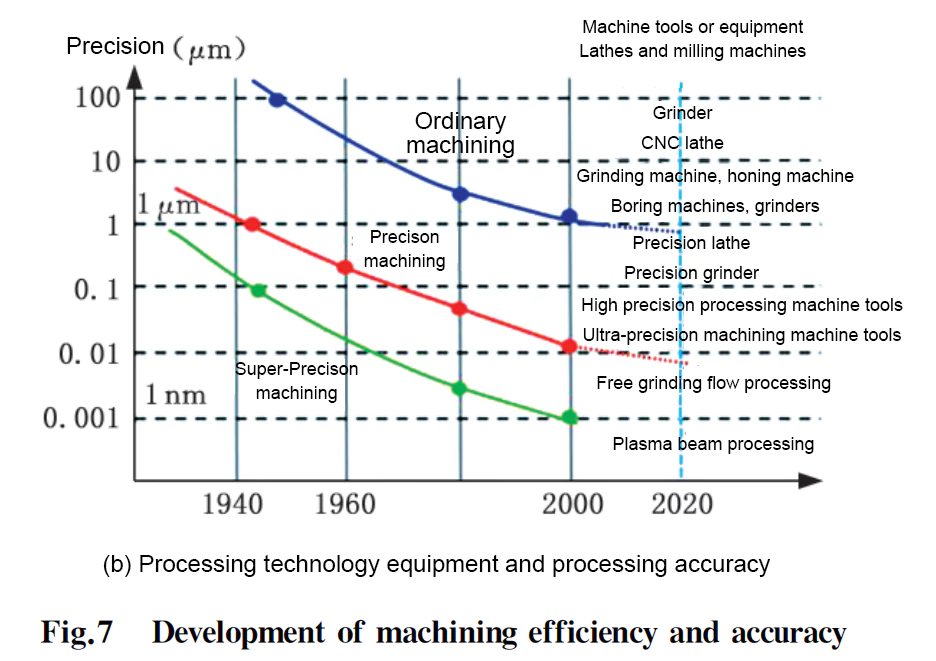

Advances in Machining Efficiency and Accuracy

The continuous progress and application of advanced manufacturing technologies have greatly shortened the machining time and improved the machining efficiency, and Fig. 7a is a widely cited curve diagram, which represents the progress of the development of advanced manufacturing technologies and machining time (efficiency). From the development trend, on the one hand, from 1960 to 2020, the total machining time (including cutting time, auxiliary time, and preparation time) in manufacturing production is reduced to 16% of the original machining time, that is, machining efficiency has increased significantly; on the other hand, “cutting time auxiliary time preparation time,” the ratio between the three also On the other hand, the ratio of “cutting time, auxiliary time and preparation time” is gradually converging.

Therefore, to improve machining efficiency in the future, we should not only focus on the optimization and improvement of process methods and increase the degree of automation but also need to effectively shorten the waiting time from the perspective of digitalization, networking, and intelligence of production management. Figure 7b is the 1980s Taniguchi to the 2020 different machine tools can achieve the processing accuracy forecast, can see that a variety of processing methods and machine tools (or equipment) technology development has brought a continuous improvement in processing accuracy, but the machining field is different from the integrated circuit manufacturing field, there is no short cycle can be effective Moore’s Law (IC can accommodate the number of transistors every 18 to 24 hours), the number of transistors every 18 to 24 hours. (the number of transistors that can be accommodated on the IC increases by a factor of 1 every 18 to 24 months), and its accuracy improvement is a long process of technology accumulation and continuous iteration (e.g., precision machining to improve 1 order of magnitude of accuracy for more than 20 years).

Current Trends and Future Outlook:

In terms of the main future development trend, the author believes that CNC machine tool technology presents the development trend of high performance, multi-functionality, customization, intelligence and green, namely:

1. High performance

The development of CNC machine tools has been striving for higher machining accuracy, cutting speed, productivity, and reliability. Future CNC machine tools will be further optimized through the machine structure, advanced control systems efficient mathematical algorithms, etc., to achieve high-speed and high-precision direct interpolation of complex curved surfaces and high dynamic response of the servo control; through the digital virtual simulation, optimization of static and dynamic stiffness design, thermal stability control, on-line dynamic compensation, and other technologies to substantially improve the reliability and accuracy of retention.

2. Multi-functional

From different cutting process composite (such as milling, milling, and grinding) to the combination of different molding methods (such as additive manufacturing, material reduction manufacturing, and other manufacturing methods such as a combination of molding methods or mixed), CNC machine tools and robots, “machine machine” fusion and synergistic and other direction of development;

From the “CAD-CAM-CNC” traditional serial process chain to the 3D solid model based on the “CAD + CAM + CNC integrated” one-step processing direction;

From the “machine-machine” interconnection network to the “human-machine-object” interconnection, edge/cloud computing support for processing large data processing direction.

3. customization

According to user needs, in the machine structure, system configuration, professional programming, cutting tools, on-machine measurement, etc. to provide customized development, in the machining process, cutting parameters, fault diagnosis, operation and maintenance, etc. to provide customized services. Modular design, reconfigurable configuration, network collaboration, software-defined manufacturing, mobile manufacturing, and other technologies will provide technical support for the realization of customization.

4. Intelligent

Through sensors and standard communication interfaces, perceive and acquire signals and data of machine tool status and machining process, learn from the machining process through transformation processing, modeling analysis, and data mining, form information and commands to support optimal decision-making, and realize monitoring, forecasting, and control of the machine tool and machining process to meet the requirements of high-quality, high-efficiency, flexible and adaptive machining.

“Perception, interconnection, learning, decision-making, adaptive” will become the main functional characteristics of intelligent CNC machine tools, processing big data, industrial Internet of Things, digital twins, edge computing/cloud computing, deep learning, and so on will be a powerful boost to the future development and progress of intelligent machine tool technology.

(5) Greening. Technology for future sustainable development needs, with eco-friendly design, lightweight structure, energy-saving and environmentally friendly manufacturing, optimal energy efficiency management, clean cutting technology, human-machine interface, and product life cycle green services.

Building on Rapid Prototyping

Over the years, the perspective on rapid prototyping has undergone changes, but its roots can be traced back to the earliest punched tape numerical control systems. Prior to this innovation, all parts had to be manually machined, making the introduction of punched tape systems a revolutionary development. In today’s world, there are numerous prototyping options available, each dependent on factors such as material selection, cost-effectiveness, and the complexity of CNC parts.

Despite the proliferation of alternative methods, CNC machines with their array of tools and rotational axes continue to possess significant appeal and utility. However, the emergence of 3D printing has revealed certain limitations in these traditional systems. 3D printers have the capability to manufacture intricate parts, including their internal components. While material options may be restricted depending on the specific application, CNC systems remain the preferred choice, particularly for the development of prototypes.

Advantages of CNC Machines

Advanced CNC machining provides numerous advantages for modern businesses. Let’s explore the various ways in which advanced CNC machines benefit industries today:

3D Imaging

The availability of CAD programs empowers individuals to create prototypes regardless of their expertise in manufacturing. Rather than requiring extensive knowledge in the field, engineers simply need to replicate their design idea in the computer to have the CNC machine bring it to life. By keeping the design in digital format, any modifications to the part’s shape can be swiftly implemented by repeating the computer processing for a new model.

Small and Large-Scale Production Capabilities

CNC machines enable businesses to handle orders ranging from a single piece for testing purposes to massive high-volume projects. This versatility allows a business to initially create a single prototype using CNC machining. Once the model has undergone physical testing and any necessary final design adjustments have been made, the finalized version can swiftly transition into high-volume production.

Quality Materials

The availability of a wide range of materials for CNC machining provides another significant advantage to this process. At American Micro Industries, we utilize various materials such as phenolics, rigid foam, plastics, and carving foam. Within each material category, there are specific types available, allowing you to select the one that best suits the desired properties for your project. Machined parts made from these materials often include electronic device cases, insulation, and prototypes. The diverse selection of material options expands the range of parts that can be created through CNC machining.

Embrace Today’s CNC Technology

Over the decades, CNC machinery technology has undergone a remarkable evolution, transitioning from punch-driven devices to computer-controlled machines. Despite these advancements, the core advantages have remained consistent: companies benefit from automated precision with significantly lower margins of error compared to what human metalworkers could achieve, all while achieving higher throughput. Moreover, the history of CNC technology is far from reaching its endpoint, as further advancements are on the horizon.

In the present day, CNC machines offer greater predictability than their predecessors. Earlier models relied on rotating motors and cam-operated control levels, which posed the risk of errors and yielded unpredictable outcomes if the feedback cable broke. With the current electronically controlled machines, such uncontrollable situations are highly unlikely. As a result, businesses can rely on CNC machines to consistently deliver the expected results.

Advanced software tools now enable businesses to create 3D models and generate precise drawings for each project. CNC machines utilize these digital designs to carve out prototypes using the highest-quality materials, bringing them to life with exceptional precision.

Throughout the changes in NC and CNC technology, the accuracy, precision, and speed of CNC machinery have significantly improved. However, there is still room for further enhancements. As engineers continue to refine CNC machinery, more companies are likely to recognize and embrace the advantages of CNC machining for their projects.