Injection Tooling

our guarantee

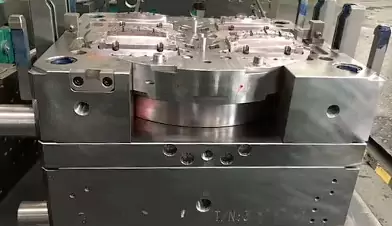

Injection tooling service

We provided best services to all customers.

We can provide customized rapid tooling and production tooling services in response to market demand to maximize customer return on investment.

Start Quote

Promise: All files are secure and confidential.

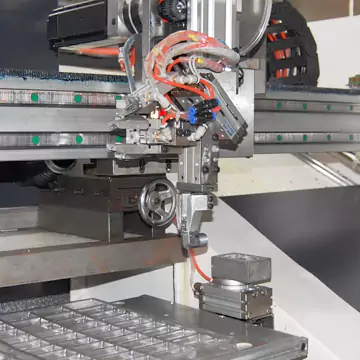

Rapid Tooling

More Affordable for Low Volume Production Rapid Tooling provides shorter lead times and lower costs. However, there is a trade-off in terms of the life cycle. Depending on the requirements, the life cycle for a rapid mold can range from a few thousand shots to over 30,000 shots. Rapid tooling offers the most cost-effective solution for low-volume productions.

Short Lead Time

Rapid tooling require fewer steps compared to traditional methods. Completing the prototype and the prototyping process swiftly enables quicker design finalization and delivery to clients.

Lower Cost

At Capblemachining, our rapid tooling can be made faster and at a lower cost than production tooling. But keep in mind that rapid tooling is only a good choice under certain conditions.

Low Volume

The quantity will be the primary factor in choosing a manufacturing method. When a certain quantity is met, injection molding offers the most cost-effective way to reduce the price per part.

Capabilities

Tooling Leading Time

Typically: 7~12 days

Plastic Parts Tolerances

Heavily depending on the plastic type and the size of the part,

Typically: +/- 0.15mm or +/-0.006 inch

Mold Core

Aluminum alloy, Carbon Steel or Tool Steel

Mold Life Cycle

Typically: 3,000

Injection Material

Most of the thermal plastic, ABS, HDPE, PE, PC, PMMA, PA6, PA66, POM, PBT, PET, PVC TPU, TPE, Silicone Rubber… Learn More >

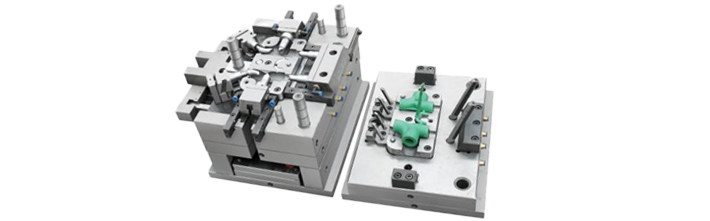

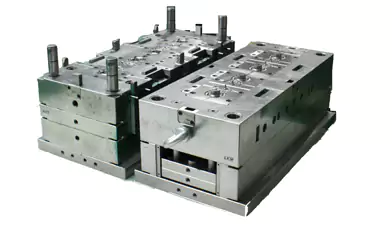

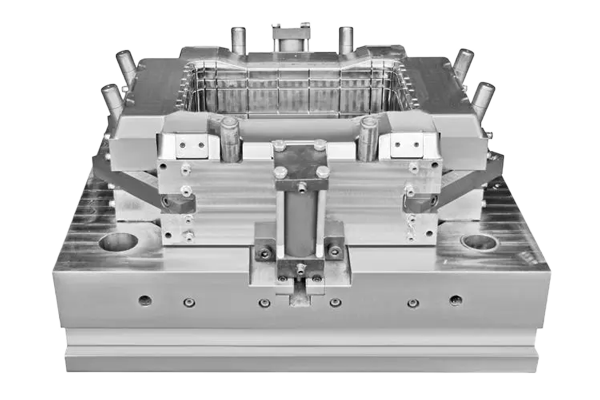

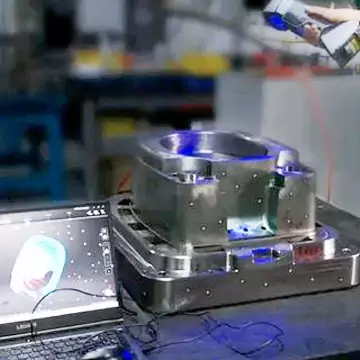

Production Tooling

We have a professional team of designing and manufacturing molds with many years of experience in the industry and can manufacture high-quality production molds for the mass production of plastic parts. Our products are made from high-strength, durable tool steel materials suitable for the production of hundreds of thousands of parts. Of course, we can also change the material and construction method according to your unique requirements. It is our goal to provide customers with high-quality services while creating maximum value for customers.

High Quality

CapableMachining with high-quality operators and a perfect quality assurance system, it can produce high-quality molds.

Fast Lead Time

We have an efficient management system and well-trained and more experiences staff, so we can provide fast lead time.

Reasonable Price

We have specialized production capacity, stable supply chain, and professional equipment to ensure more reasonable prices for customers.

Capabilities

We design and manufacture precise custom injection molds from premium materials. We have a complete quality assurance system to ensure the quality of the products and all meet international standards, and an efficient team to provide fast delivery time.

| Purpose | Life Cycle | Tolerance | Material | Cost | Lead Time | |

|---|---|---|---|---|---|---|

| Technology | Prototy Testing | 3,000 | ± 0.02mm | Alumnuim Alloy | $$ | 7-15 Day |

| Rapid tooling | Low-volume Production | 30,000 | ± 0.02mm | Carbon Steel | $$ | 7-15 Day |

| Production tooling | Medium-volume Production | 300,000 | ± 0.02mm | Harden Tool Steel | $$$ | 30 Day |

| High-volume Production | Over 1,000,000 | ± 0.02mm | Harden Tool Steel (Surface) | $$$$ | 35 Day |

The Two Tooling Difference

Rapid tooling means making tools quickly and inexpensively for traditional manufacturing. These tools help create parts fast or in small amounts.

Production tools are often made from strong metals using processes like cutting and casting. But these are costly and better for making lots of things. When used for making a few tools or parts, they cost more and take longer.

| Rapid Tooling | Conventional Tooling | |

|---|---|---|

| Speed | 7~15 days |

4~8 weeks |

| Tooling cost | low overhead costs | considerable overhead costs. |

| Ideal production volume | 1000 ~ 30,000 parts, depending on the process and tooling material | ~30k + parts, varies by production process |

| Applications | Product validation testing Bridge tooling Short run, on-demand, or custom production |

Mass production |

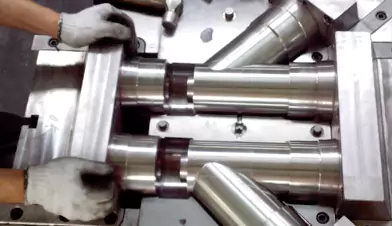

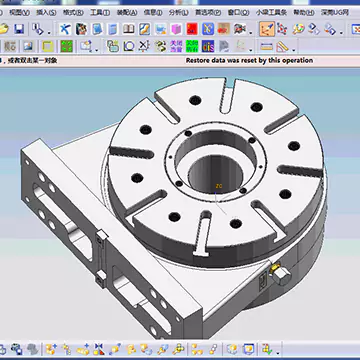

General Workflow of Tooling

1. Stp File && Information Sent

2. Quotation

3. Customer place an order

4. We send detail DFM

5. Make the mold

6. T0 (first time test molding)

7. T1 (second test molding)

8. Check before acceptance

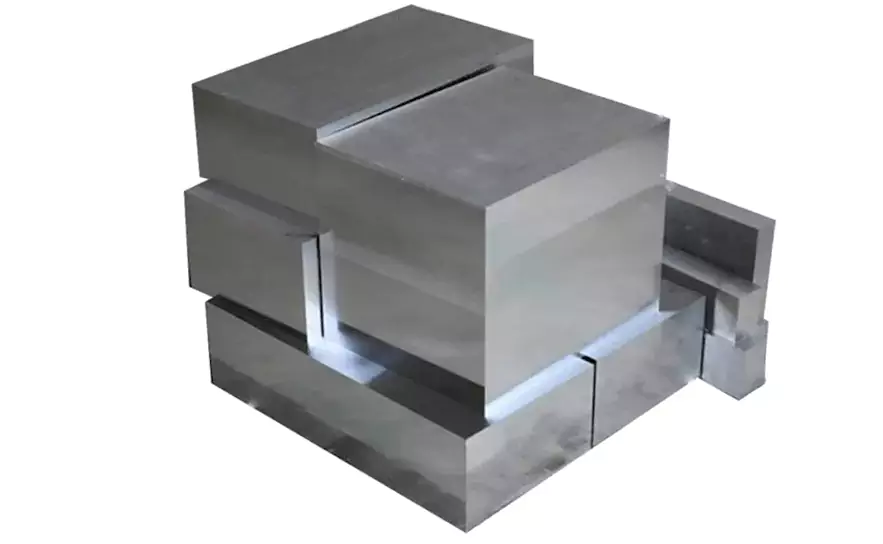

Common Tooling Materials

The choice of mold manufacturing material is of great importance, because it determines its service life and the quality of injection molded parts. We have a variety of materials that are suitable for the manufacture of different grades of molds, and our professionals also provide customers with professional advice to help customers make suitable choices.

Tool Steel

The most commonly used material for mold making is tool steel. It is easy to process and affordable. It is very suitable for molds used before low-volume or high-volume production.

| Name | Feature | Application |

|---|---|---|

| P20 | Good processability and mechanical properties | Small injection volume and low pressure molds |

| 718 | Good wear and corrosion resistance | Large injection volume and high pressure molds |

| NAK80 | Good wear and corrosion resistance | High-precision, small and medium-sized injection volume |

| S136 | Good wear and corrosion resistance | High-precision injection molds and optical molds |

| H13 | Good wear and corrosion resistance | High quality injection mold |

Aluminum Alloy

Aluminum molds cost significantly less than traditional steel and carbon steel injection molds. Its faster manufacturing cycle and lower price can help customers launch products quickly.

| Subtypes | Yield Strength | Elongation at Break | Hardness | Feature |

|---|---|---|---|---|

| 6061-T6 | 35,000 psi | 12.50% | Brinell 95 | Higher intensity, Harden Alunuim |

| 7075-T6 | <68,000 psi | 11% | Brinell 126 | Good wear and corrosion resistance |

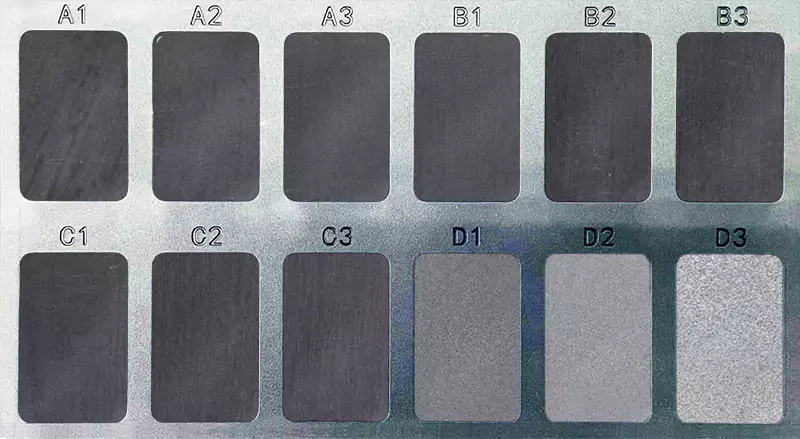

Surface Textures

We have experienced professionals for surface treatment of molds.

| Name | Description | SPI | Guide | R.A Value | Typical applications | Injection Plastic material |

|---|---|---|---|---|---|---|

| Glossy | The diamond buffing process is employed to create polished and lustrous finishes on the injection mold, constituting the result of a grade. This procedure is notably time-intensive, with the choice of steel grade significantly influencing the ultimate outcome. | A1 | Grade #3 Diamond | 0-1 | Lens / Mirror – requires 420 SS material | Acrylic |

| A2 | Grade #6 Diamond | 1-2 | High Polish parts | Acrylic, PC | ||

| A3 | Grade #15 Diamond | 2-3 | High Polish parts | ABS, Acrylic. PS, Nylon, PC | ||

| Semi-glossy | Utilizing grit sandpaper, B-grade finishes are employed to craft components featuring a subtle and matte surface texture, effectively eliminating all traces of tooling and machining imprints. | B1 | 600 Grit paper | 2-3 | Medium Polish parts | ABS, Acrylic, PP. PS, HDPE, Nylon, PC |

| B2 | 400 Grit paper | 4-5 | Medium Polish | ABS, Acrylic, PP. PS, HDPE, Nylon, PC | ||

| B3 | 320 Grit paper | 9-10 | Med – Low polish | ABS, Acrylic, PP. PS, HDPE, Nylon | ||

| Matte | Grit sanding stones are employed in C-grade finishes to create an intentionally coarse and uneven surface. This process effectively eradicates tool and machining marks while enhancing mold release properties. The resulting mold surface exhibits a muted matte texture, devoid of any shine or sheen. | C1 | 600 Stone | 10-12 | Low Polish parts | ABS, Acrylic, PP. PS, HDPE, Nylon, TPU |

| C2 | 400 Stone | 25-28 | Low Polish parts | ABS, Acrylic, PP. PS, HDPE, Nylon, TPU | ||

| C3 | 320 Stone | 38-42 | Low Polish parts | ABS, Acrylic, PP. PS, HDPE, Nylon, TPU | ||

| Textured | In D-grade finishes, a combination of grit and dry glass beads or oxide is harnessed to generate an exceedingly rugged textured outcome, serving to conceal shrink marks and other flaws. The final appearance varies based on the material employed, potentially resulting in a satin or non-reflective finish for the products. | D1 | Dry Blast Glass Bead | 10-12 | Satin finish | ABS, PP. PS, HDPE, Nylon, PC, TPU |

| D2 | Dry Blast # 240 Oxide | 26-32 | Dull Finish | ABS, PP. PS, HDPE, Nylon, TPU | ||

| D3 | Dry Blast # 24 Oxide | 190-230 | Dull Finish | ABS, PP. PS, HDPE, Nylon, TPU |

Frequently Asked Questions

Currently, we don’t provide design services, just focus on CNC machining. Although we do have engineers capable of making CAD designs, designing involves intensive knowledge in the field of the product required. Our specialty is converting a design to real not converting an idea to a design.

Yes, we are happy to help you with our knowledge of materials. Please send us the information, we will arrange for engineers to sort it out.

Yes, we do. We manufacture gear, worm, helical gear and some bevel gear in our CNC machining service.

No, we don’t manufacture wood product.

We don’t do 3D print ourself, if you need them, we can outsources for you.

Yes, we do. We do part marking with silk screening, laser engraving, and etching. If you need such service, please send design of the marking in .ai or .dwg form.

Yes we can. 2D drawing contains important information like tolerances, heat treatment, surface treatment etc. Without we will following ISO2768 medium for metal parts and ISO2768 coarse for plastic parts as default, and no heat treatment, no surface treetment, unless otherwise claimed.

The answer is case by case. It depends on if we have the assembly equipments and environment. If it is a simple assembly and we have the equipments, we will offer assembly service.

Stp file is an standard 3D file that all CAD and CAM programes (Proe, UG, Solidworks etc.) can open and convert to. If you only have CAD files with other file extension, send to us, we can covert it to stp file.

Related Blog

Application and development trend of rapid tooling manufacturing

As people’s quality of life has improved, the demand for various products has increased, and r…

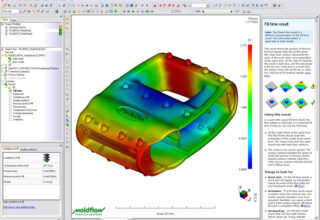

How to analyze and optimize the mold flow of injection molded parts?

A set of high-quality injection molds is inseparable from reasonable design and exquisite processing…

Modern injection mold manufacturing technology and its development trend

In modern industry, there is a very crucial field called the mold industry. Mold technology is indis…