Fort Collins

Plastic injection molding for Fort Collins, Colorado

Receive top-tier engineering services from a seasoned manufacturer with a track record of professionalism and excellence.

Custom Parts, On Demand Manufacturing

Explore our premier Plastic injection molding services in Fort Collins, Colorado

specializing in plastic prototypes and production parts.

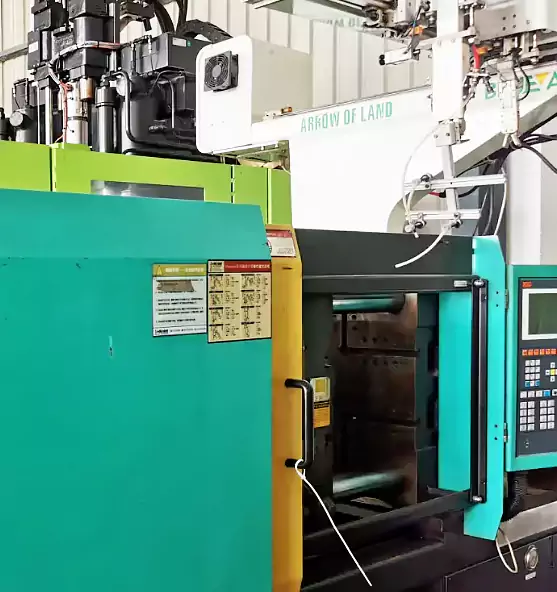

Welcome to CapableMachining, your one-stop destination for high-quality plastic injection molding services. With years of experience and expertise in the industry, we specialize in providing top-notch solutions for all your molding needs. Our state-of-the-art facilities and cutting-edge technology allow us to deliver precise and efficient results, no matter the complexity of the project. Whether you are looking for prototyping, low volume production, or high-volume manufacturing, our team of expert engineers and technicians are committed to meeting your requirements with precision and accuracy.

Trust CapableMachining to bring your ideas to life with our reliable and cost-effective plastic injection molding services. Contact us today to discuss your project requirements and take the first step towards creating superior quality products.

Why Choose Us?

Our ability to provide on-demand manufacturing services means not only having strong manufacturing capabilities but also services that can produce complex end-use parts quickly, efficiently, and intelligently.

Our services

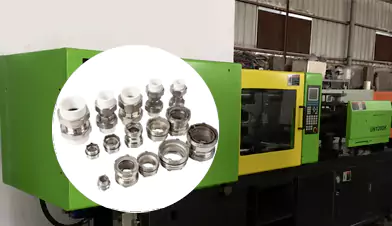

Injection molding stands as the predominant approach for mass-producing plastic goods. This method involves melting plastic, injecting it into molds, ejecting the finalized product, and then repeating the cycle.

Insert molding proves to be a highly practical injection molding technique that enhances the strength or other properties of the final part by integrating additional materials.

Overmolding is a process where various materials are layered to create a composite article. Typically, this method entails injecting a base material over one or more pre-existing parts to integrate them into a unified whole.

Other services

Capabilities

Tolerances

Heavily depending on the plastic type and the size of the part, typically +/- 0.15mm or +/-0.006 inch

Mold Life Cycle

Typically 300,000, and 600,000 if required.

Leading Time

Typically: tooling 30 days, injection molding 3 days

Injection Material

Most of the thermal plastic, ABS, HDPE, PE, PC, PMMA, PA6, PA66, POM, PBT, PET, PVC TPU, TPE, Silicone Rubber… Learn More >

Materials

Selecting the right material is momentous, not only for factors such as cost, processing complexity, and potential surface treatments but also for the ultimate quality of the product. Our competent engineering team specializes in proactively addressing this challenge, even before an order is placed. This process safeguards that our customers have the solid belief in the final quality of their products.

Rigid Materials

Hard plastic materials are defined as materials that show primarily no elastic deformation and no complete plastic deformation. Wefoster prolonged teamwork quality suppliers, which enables us to provide quality assurance to our customers as well as to fulfill assorted specialized requirementsof our customers.

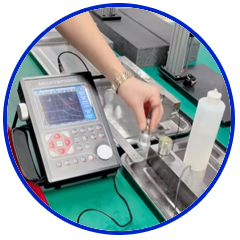

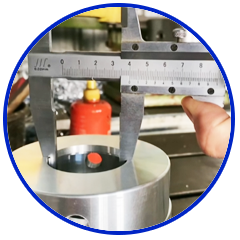

Our Quality Control

CapableMachining boasts a reputable quality assurance framework and a team of expert technical engineers who diligently oversee every aspect of our product manufacturing process – from procuring high-quality raw components to delivering impeccable finished goods that encompass metals and plastics. To sustain our dedication to superiority, we extensively utilize advanced testing technology and cutting-edge equipment to meticulously evaluate crucial parameters such as workpiece dimensions, hardness, tensile strength, and elongation at every stage of production. We aim for maintain utmost control over these data points to meet and surpass the expectations of our esteemed clientele consistently.

Professional quality control Engineer

Tolerances up to ±0.0004″ (0.01mm)

State-of-the-art Inspection Facilities

Proven and reliable quality control system.

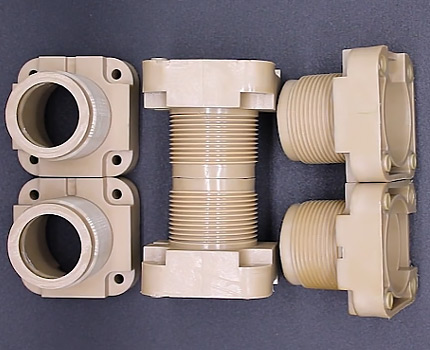

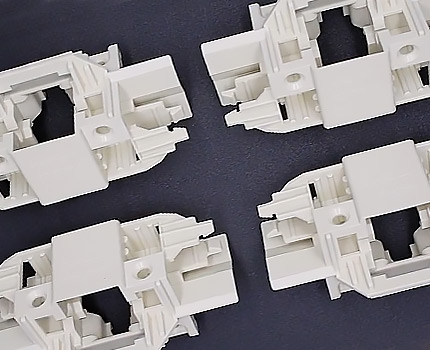

Gallery of Parts

Charging Plug

Material: ABS

Industry equipment part

Material: PEEK

Telecom equipment part

Material: PA66

Auto bumper

Material: ABS

UAV blades

Material: PPA + 30 Carbon Fiber

Medical container

Material: PE

Other capabilities

- Free & Automatic DFM feedback

- Tolerances: typically +/- 0.15mm or +/-0.006 inch

- Tooling: 30 days

- Free advices from high trained engineers.

- Quotation in a few hours.leading time 3 days

- Fast delivery time

- Tolerances: typically +/- 0.15mm or +/-0.006 inch

- Free consultant ,Free DFM feedback

- Casting lead time: 5~7 days

- Wide range of material choices

- Free consultant from engineers

- Fastest leading time: 1 day

- Free & Automatic DFM feedback

- Tolerances up to ±0.00078″ (0.02mm)

- Rapid tooling: 7~12 days

How do find our location?

Other Location Near me

FAQ

Introduction

Plastic injection molding is a widely used manufacturing process in Fort Collins, Colorado. It involves melting plastic and injecting it into a mold to create various products. Understanding the ins and outs of this process is essential for businesses looking to utilize this manufacturing technique effectively.

Q: What is plastic injection molding?

A: Plastic injection molding is a manufacturing process where molten plastic is injected into a mold cavity under high pressure. Once the plastic cools and hardens, the mold is opened, and the finished product is ejected.

Q: What are the advantages of plastic injection molding?

A: Some advantages of plastic injection molding include high production rates, repeatable and consistent product quality, design flexibility, and cost-effectiveness for large production runs.

Q: What materials can be used in plastic injection molding?

A: A wide variety of thermoplastics and thermosetting polymers can be used in plastic injection molding, including ABS, polypropylene, polycarbonate, and nylon.

Q: How long does the plastic injection molding process take?

A: The time it takes to complete a plastic injection molding process can vary depending on the complexity of the part, the material used, and the size of the production run. However, most molding cycles range from a few seconds to a few minutes.

Q: What industries use plastic injection molding in Fort Collins?

A: Industries such as automotive, medical, aerospace, consumer goods, and electronics utilize plastic injection molding in Fort Collins for the production of various components and products.

Q: What are some common challenges in plastic injection molding?

A: Common challenges in plastic injection molding include achieving uniform wall thickness, preventing warping or shrinkage, ensuring proper cooling, and addressing potential defects like sink marks or flash.

Q: What is the importance of mold design in plastic injection molding?

A: Mold design plays a crucial role in the success of a plastic injection molding process. Proper mold design can help prevent defects, optimize cycle times, and ensure the production of high-quality parts.

Q: How can businesses benefit from outsourcing plastic injection molding?

A: Outsourcing plastic injection molding can help businesses reduce costs, access specialized expertise and equipment, increase production capacity, and focus on core competencies.

Q: What are some environmental considerations in plastic injection molding?

A: Environmental considerations in plastic injection molding include material selection, recycling and reuse of scrap plastic, energy efficiency in production processes, and compliance with regulations and standards.

Q: How can businesses improve efficiency in plastic injection molding?

A: Businesses can improve efficiency in plastic injection molding by optimizing mold design, streamlining production processes, monitoring and controlling variables like temperature and pressure, and implementing continuous improvement initiatives.

Conclusion

Plastic injection molding is a versatile and efficient manufacturing process that many industries in Fort Collins rely on for the production of high-quality products. By understanding the fundamentals of plastic injection molding and addressing common challenges, businesses can maximize the benefits of this manufacturing technique and stay competitive in the market.

The personnel at CapableMachining has supported us in crafting our concepts into final products for several years now. The process from initiation to production has been continuous, thanks to their know-how, talents, and positive mindset.

The employees at CapableMachining has backed us in bringing our ideas to fruition into finished parts for several years now. The process from design to assembly has been uninterrupted, thanks to their know-how, capabilities, and can-do spirit.

Henceforth, CapableMachining has continuously delivered us with exceptional parts. We’ve onboarded a good support team to create injection mold for us, rectify and customize present molds to accommodate our requirements, and provide merchandise that consistently meets or surpasses our demanding specifications.