McKinney

Plastic injection molding for McKinney, Texas

Receive top-tier engineering services from a seasoned manufacturer with a track record of professionalism and excellence.

Custom Parts, On Demand Manufacturing

Explore our premier Plastic injection molding services in McKinney, Texas

specializing in plastic prototypes and production parts.

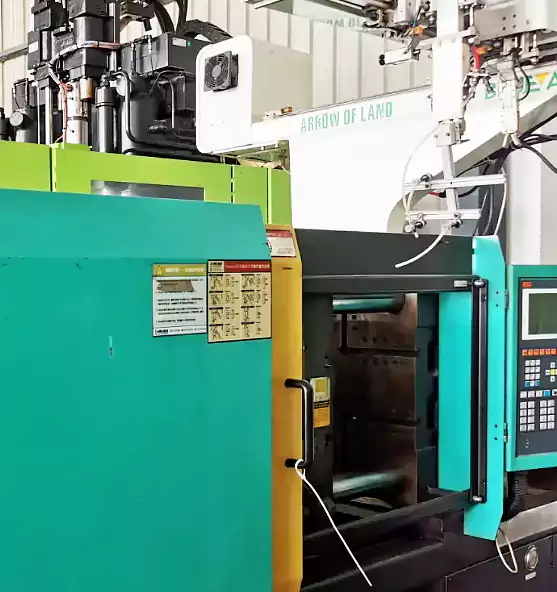

Welcome to CapableMachining, the premier provider of plastic injection molding services. With state-of-the-art technology and a team of experienced professionals, we offer precision molding solutions for a wide range of industries. Our advanced equipment and expertise allow us to produce high-quality plastic parts with tight tolerances and exceptional consistency. Whether you need prototypes, low-volume production, or high-volume manufacturing, we have the capabilities to meet your needs. Contact us today to learn more about our plastic injection molding services and how we can help bring your ideas to life.

Why Choose Us?

Our ability to provide on-demand manufacturing services means not only having strong manufacturing capabilities but also services that can produce complex end-use parts quickly, efficiently, and intelligently.

Our services

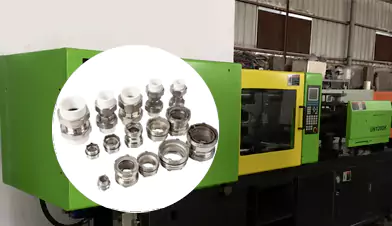

Injection molding stands as the predominant approach for mass-producing plastic goods. This method involves melting plastic, injecting it into molds, ejecting the finalized product, and then repeating the cycle.

Insert molding proves to be a highly practical injection molding technique that enhances the strength or other properties of the final part by integrating additional materials.

Overmolding is a process where various materials are layered to create a composite article. Typically, this method entails injecting a base material over one or more pre-existing parts to integrate them into a unified whole.

Other services

Capabilities

Tolerances

Heavily depending on the plastic type and the size of the part, typically +/- 0.15mm or +/-0.006 inch

Mold Life Cycle

Typically 300,000, and 600,000 if required.

Leading Time

Typically: tooling 30 days, injection molding 3 days

Injection Material

Most of the thermal plastic, ABS, HDPE, PE, PC, PMMA, PA6, PA66, POM, PBT, PET, PVC TPU, TPE, Silicone Rubber… Learn More >

Materials

Electing the right material is paramount, not only for factors such as cost, processing complexity, and potential surface treatments but also for the ultimate quality of the product. Our experienced engineering team specializes in proactively addressing this challenge, even before an order is placed. This process validates that our customers have the full assurance in the final quality of their products.

Rigid Materials

Rigid plastic materials are defined as materials that signify primarily no elastic deformation and no complete plastic deformation. Wemaintain long-term cooperation with quality suppliers, which enables us to provide quality assurance to our customers as well as to satisfy assorted specific needsof our customers.

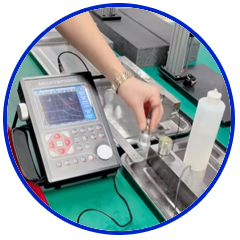

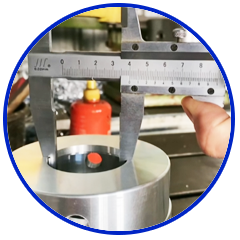

Our Quality Control

CapableMachining boasts a standard quality assurance framework and a team of competent technical engineers who diligently oversee every aspect of our product manufacturing process – from sourcing top-notch raw ingredients to delivering impeccable finished goods that encompass metals and plastics. To keep our dedication to excellence, we extensively utilize advanced testing technology and cutting-edge equipment to meticulously evaluate crucial parameters such as workpiece dimensions, hardness, tensile strength, and elongation at every stage of production. We seek to maintain utmost control over these data points to meet and surpass the expectations of our esteemed clientele consistently.

Professional quality control Engineer

Tolerances up to ±0.0004″ (0.01mm)

State-of-the-art Inspection Facilities

Proven and reliable quality control system.

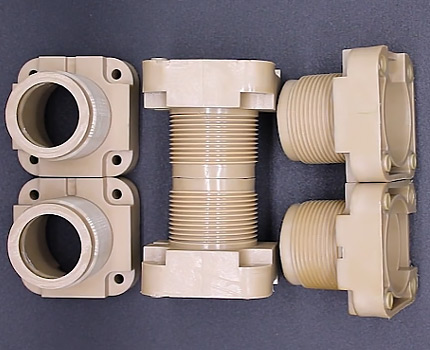

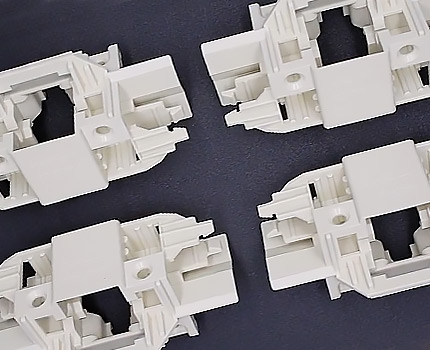

Gallery of Parts

Charging Plug

Material: ABS

Industry equipment part

Material: PEEK

Telecom equipment part

Material: PA66

Auto bumper

Material: ABS

UAV blades

Material: PPA + 30 Carbon Fiber

Medical container

Material: PE

Other capabilities

- Free & Automatic DFM feedback

- Tolerances: typically +/- 0.15mm or +/-0.006 inch

- Tooling: 30 days

- Free advices from high trained engineers.

- Quotation in a few hours.leading time 3 days

- Fast delivery time

- Tolerances: typically +/- 0.15mm or +/-0.006 inch

- Free consultant ,Free DFM feedback

- Casting lead time: 5~7 days

- Wide range of material choices

- Free consultant from engineers

- Fastest leading time: 1 day

- Free & Automatic DFM feedback

- Tolerances up to ±0.00078″ (0.02mm)

- Rapid tooling: 7~12 days

How do find our location?

Other Location Near me

FAQ

Ten Common Questions About Plastic Injection Molding in McKinney

Plastic injection molding is a widely used manufacturing process in McKinney, Texas. It involves creating plastic parts by injecting molten material into a mold. If you’re considering plastic injection molding for your business, you may have some questions. Here are ten common questions about plastic injection molding in McKinney, along with their answers.

Q: What is plastic injection molding?

A: Plastic injection molding is a manufacturing process that involves injecting molten plastic material into a mold to create plastic parts.

Q: How is plastic injection molding different from other manufacturing processes?

A: Plastic injection molding is often faster and more cost-effective than other manufacturing processes, making it a popular choice for producing high volumes of plastic parts.

Q: What types of materials can be used in plastic injection molding?

A: A wide variety of plastic materials can be used in plastic injection molding, including thermoplastics, thermosets, and elastomers.

Q: What industries commonly use plastic injection molding?

A: Industries such as automotive, consumer goods, electronics, and medical devices commonly use plastic injection molding to produce plastic parts for their products.

Q: What are the benefits of plastic injection molding?

A: Some benefits of plastic injection molding include high production efficiency, design flexibility, and the ability to create complex shapes and features.

Q: How can I choose the right plastic injection molding company in McKinney?

A: When choosing a plastic injection molding company, consider factors such as experience, capabilities, quality standards, and customer reviews.

Q: What are the steps involved in the plastic injection molding process?

A: The plastic injection molding process typically involves mold design, material selection, melting and injecting the plastic material into the mold, cooling, and ejecting the finished part.

Q: How can I ensure the quality of plastic injection molded parts?

A: Quality control measures such as regular inspections, testing, and adherence to industry standards can help ensure the quality of plastic injection molded parts.

Q: What are some common challenges in plastic injection molding?

A: Common challenges in plastic injection molding include warping, sink marks, flash, and short shots, which can be addressed through proper mold design and process optimization.

Q: How can I reduce costs in plastic injection molding?

A: To reduce costs in plastic injection molding, consider factors such as material selection, part design optimization, process efficiency, and working with a reputable and experienced plastic injection molding company.

Conclusion

Plastic injection molding is a versatile and widely used manufacturing process in McKinney, offering numerous benefits for businesses in various industries. By understanding the common questions and answers about plastic injection molding, you can make informed decisions and find the right plastic injection molding company to meet your needs.

we have been teaming up with CapableMachining for years. These guy listen to customers and react with extensive technical prowess in resources, component design, and procedure possibilities. This has been and will be an indispensable part of our success.

They has been a excellent and strategic ally for us right from the beginning. The process from formulation to manufacturing has been seamless, thanks to their know-how, talents, and positive mindset.