CNC Machining in Automotive: Diverse Applications, Advantages

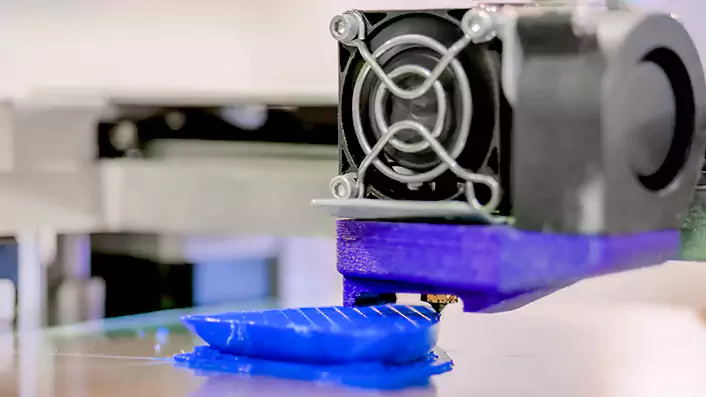

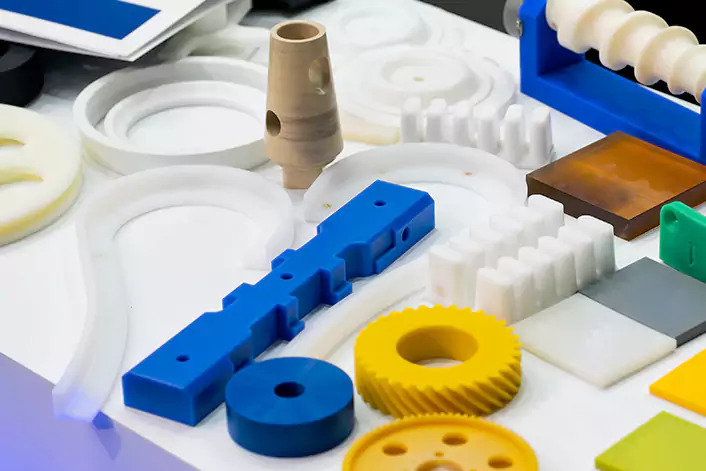

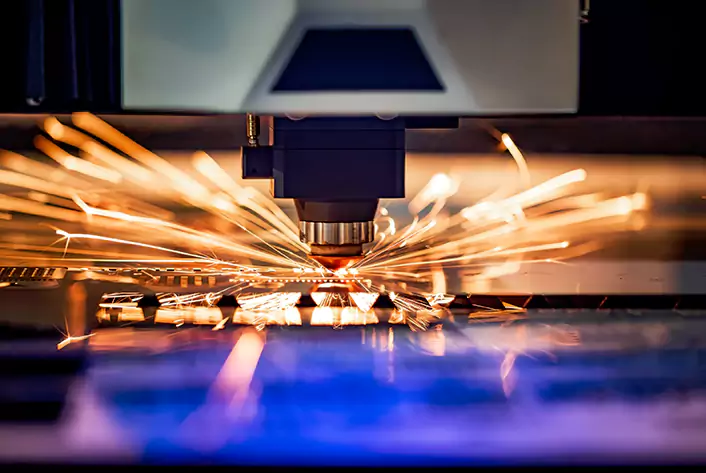

CNC machining, or computer numerical control machining, is a manufacturing process that utilizes pre-programmed computer software to control machine tools and operate complex machinery. The automotive industry is one of the largest consumers of CNC machining services due to its ability to produce high-quality, precise, and consistent vehicle parts that meet the industry's stringent requirements.