What is 5-axis CNC milling and how does it work?

In today’s manufacturing and engineering industries, precision, accuracy, and efficiency are paramount. This is where 5-axis CNC milling comes into play. 5-axis CNC milling is an advanced technology that enables the production of complex and intricate parts with unparalleled precision and efficiency. It is used in a wide range of industries, from aerospace and automotive to medical and mold and die making. In this article, we will explore the basics of CNC machining, the axes system used in 5-axis CNC milling, the tools and machines used, and how 5-axis CNC milling works. We will also discuss the benefits and limitations of this technology and its future prospects. So, let’s dive in and learn more about 5-axis CNC milling and how it works.

What is CNC Milling

CNC milling is a type of subtractive manufacturing process that uses a computer-controlled machine to remove material from a workpiece. This process involves creating a digital design of the part to be manufactured, which is then loaded into the CNC machine. The machine uses this design to control the movement of the cutting tool, which removes material from the workpiece to create the desired shape.

There are several types of CNC milling machines, including vertical, horizontal, and gantry mills. Each of these machines has its own unique capabilities and advantages, depending on the specific needs of the manufacturer or engineer.

One of the main advantages of CNC machining over traditional methods is the increased precision and accuracy that can be achieved. CNC machines can handle complex geometries and shapes with extreme accuracy, making them ideal for applications where precision is critical.

Understanding the Axes System

In CNC machining, the axes system is used to define the motion of the cutting tool relative to the workpiece. This system consists of several axes that control the movement of the CNC machine in different directions.

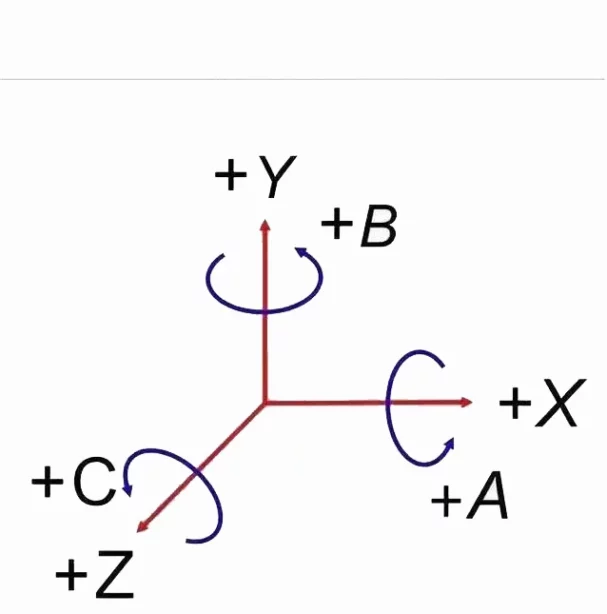

The most common axes system used in CNC milling is the XYZABC system, referring to two horizontal axes, two rotational axes, and one vertical, where:

● X-axis: Horizontal movement from left to right

● Y-axis: Horizontal movement from front to back

● Z-axis: Vertical movement up and down

● A-axis: Rotational movement around the X-axis

● B-axis: Rotational movement around the Y-axis

● C-axis: Rotational movement around the Z-axis

This system allows the cutting tool to move in six different directions, allowing for complex cuts and contours.

Another way of defining the axes system is the UVW system, which is commonly used in 5-axis CNC machining. In this system, the U, V, and W axes are defined as follows:

● U-axis: Parallel to the X-axis

● V-axis: Parallel to the Y-axis

● W-axis: Parallel to the Z-axis

These axes are used to control the orientation of the workpiece relative to the cutting tool, allowing for greater flexibility in the machining process.

How 5-axis CNC Milling Works

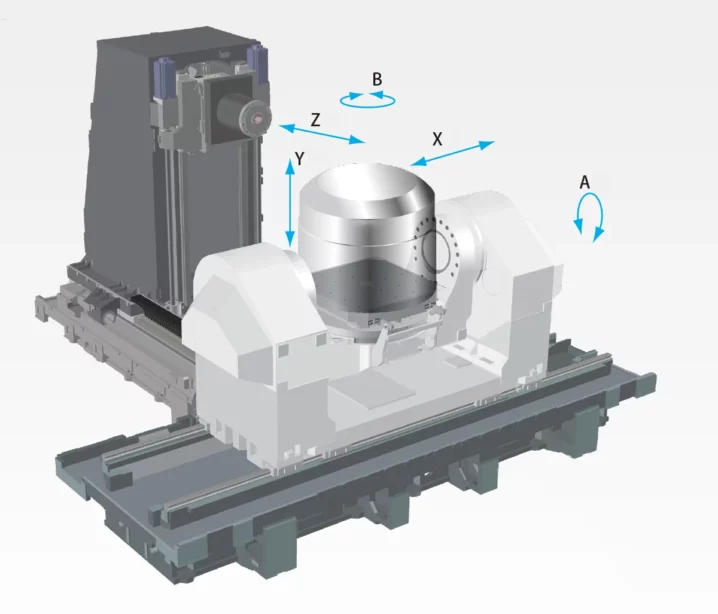

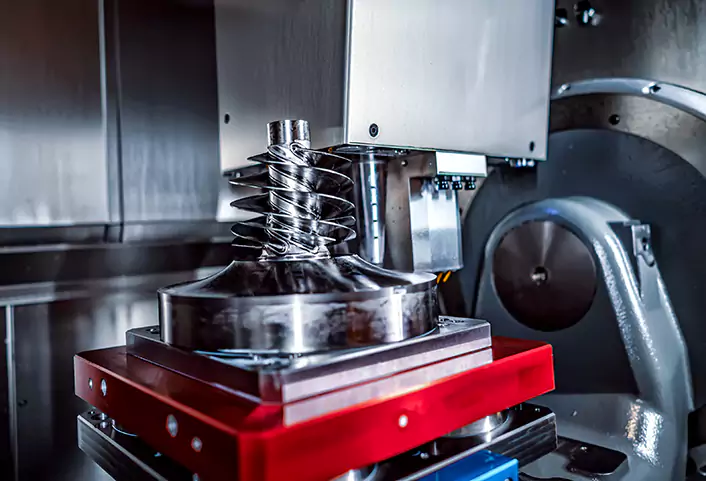

5-axis CNC mills differ from 3-axis or 4-axis machines in that they have an additional rotational axe (A or B) that allows for more complex and intricate cuts. This axis tool rotates the workpiece or cutting tool around a fixed axis, allowing for cuts and contours at various angles and orientations.

The advantages of 5-axis CNC milling

1. Greater flexibility – With an additional axis, the 5-axis CNC mill can create more complex and intricate parts with ease. This flexibility allows manufacturers to create parts with more complex geometries and designs.

2. Improved efficiency – 5-axis CNC mill can significantly reduce the time and labor required for part setup, as it allows for multiple cuts and contours to be made in a single setup.

3. Improved accuracy – By allowing for cuts at various angles and orientations, a 5-axis CNC mill can increase accuracy and surface quality.

Applications of 5-axis CNC milling

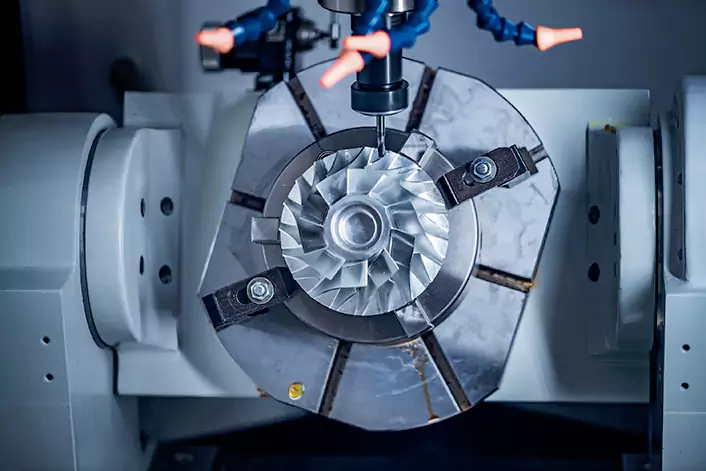

1. Aerospace – 5-axis CNC machining is commonly used in the aerospace industry for the production of intricate parts, such as engine components and wing sections.

2. Medical – Medical device manufacturers use 5-axis CNC machining to produce complex and intricate parts, such as surgical implants and prosthetics.

3. Automotive – 5-axis CNC machining is used in the automotive industry for the production of complex parts, such as engine blocks and transmission components.

4. Mold and die making – 5-axis CNC machining is used in mold and die making for the production of complex shapes and geometries, such as injection molds and die-cast dies.

5-axis CNC milling is an advanced high-speed machining technology that allows for complex and intricate cuts and contours. With its additional axes, 5-axis CNC milling offers greater flexibility, improved efficiency, and improved accuracy, making it a popular choice for different industries, including aerospace, medical, automotive, and mold and die-making.

Tools and Machines Used in 5-axis CNC Milling

To achieve the precision and accuracy required for 5-axis CNC machining, specialized tools, and machines are required. Here are the tools, machines, and software typically used in 5-axis CNC machining:

Tools and Cutters Used in 5-axis CNC Milling

The shorter cutting tools used in 5-axis CNC milling are typically high-speed steel or carbide tools. These tools come in a variety of shapes and sizes to allow for the creation of a wide range of shapes and geometries.

Some of the most common types of cutting tools used in 5-axis CNC milling include ball end mills, the bull nose end mills, and tapered end mills. Each of these tools has its own unique shape and cutting profile, allowing for the creation of highly specific geometries.

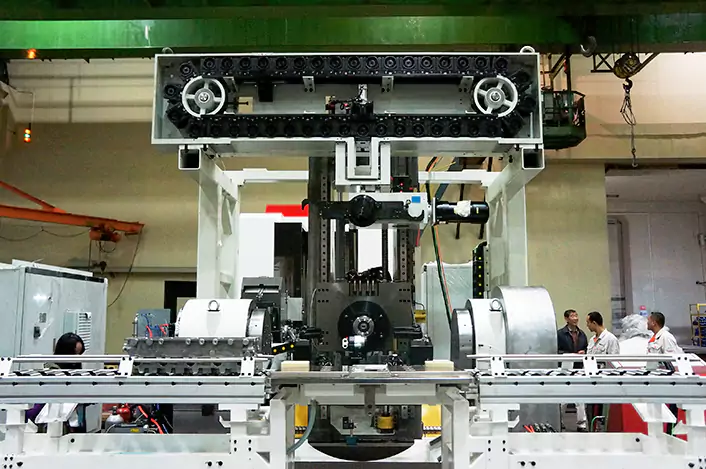

Types of Machines Used in 5-axis CNC Milling

There are several types of machines used in 5-axis CNC machining, each with its own unique capabilities and advantages. Some of the most common types of machines used in 5-axis CNC machining include:

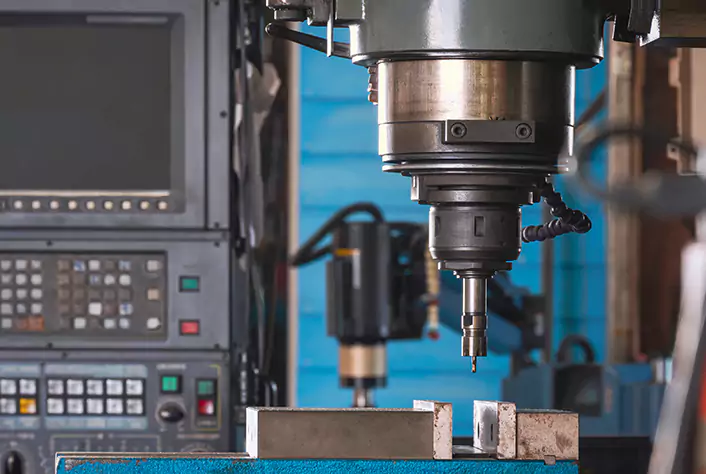

1. Vertical Machining Centers (VMCs) – VMCs are some of the most common types of 5-axis CNC machines. They are typically used for cutting small to medium-sized parts and are known for their versatility and flexibility.

2. Horizontal Machining Centers (HMCs) – HMCs are similar to VMCs but are designed for cutting larger parts. They are often used in industries such as aerospace and automotive manufacturing.

3. Gantry Mills – Gantry mills are large, heavy-duty machines that are capable of cutting very large parts. They are often used in the production of molds, dies, and other large components.

Software Used in 5-axis CNC Milling

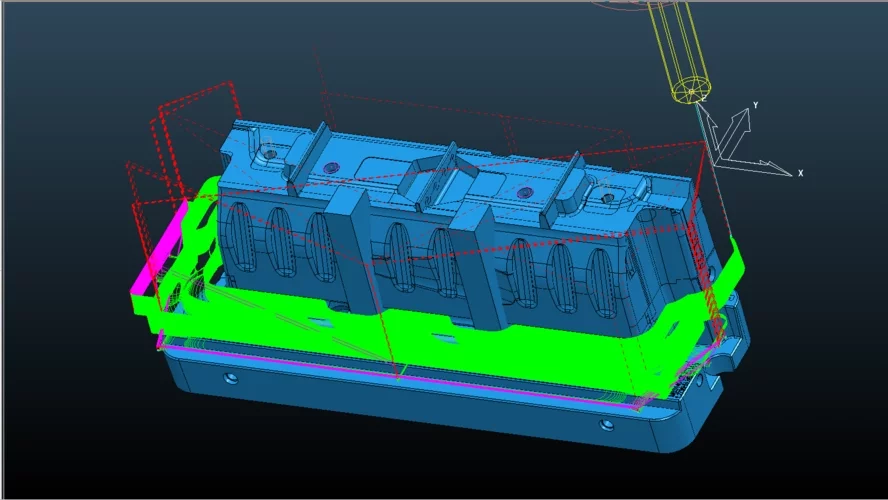

In addition to specialized machines and cutting tools, the software is also a critical component of 5-axis CNC milling. This software is used to create digital designs that are loaded into the CNC machine to control the cutting process.

Some of the most common software programs used in 5-axis CNC milling include:

1. Computer-Aided Design (CAD) software – CAD design software is used to create digital designs that are loaded into the CNC machine.

2. Computer-Aided Manufacturing (CAM) software – CAM software is used to generate the tool paths that the cutting tool will follow to create the desired shape.

3. Simulation software – Simulation software is used to test and optimize the cutting process before the actual machining takes place.

Benefits and Limitations of 5-axis Milling

5-axis CNC milling has several benefits that make it an attractive option for many manufacturers and engineers. However, there are also some limitations that need to be considered before deciding to invest in this technology.

Benefits of 5-axis CNC Milling

1. Precise cuts – 5-axis CNC milling allows for extremely precise cuts and contours, resulting in parts with high accuracy and surface finish quality.

2. Reduced setup time – The ability to cut complex geometries in a single setup reduces the time and labor required for part setup, resulting in increased efficiency and productivity.

3. Versatility – 5-axis CNC machines can produce a wide variety of parts and components, from small and intricate to large and complex.

4. Reduced scrap – With its high precision and accuracy, 5-axis CNC milling can significantly reduce scrap and waste material, resulting in cost savings and environmental benefits.

5. Reduced lead time – By eliminating the need for multiple setups and reducing scrap, 5-axis CNC milling can shorter lead times and improve turnaround times for parts production.

Limitations of 5-axis CNC Milling

1. Cost – 5-axis CNC machines are typically more expensive than 3-axis or 4-axis machines, which can be a significant investment for smaller manufacturers or businesses.

2. Complexity – 5-axis CNC machines require specialized training and expertise to operate and program, which can be a challenge for some businesses.

3. Maintenance – 5-axis CNC machines require regular maintenance and upkeep to ensure optimal performance and longevity.

4. Size limitations – While 5-axis CNC machines are capable of producing large parts, there are still size limitations depending on the specific machine and application.

5. Software limitations – While the software is critical for 5-axis CNC milling, there are limitations in the software’s ability to create complex geometries or handle large data sets, which can impact the machine’s performance.

Generally speaking, 5-axis CNC milling offers numerous benefits, including high precision and accuracy, reduced setup time, versatility, and reduced scrap. However, there are also some limitations to consider, such as cost, complexity, maintenance requirements, size limitations, and software limitations. Careful consideration of these factors is necessary to determine if 5-axis CNC milling is the right choice for a particular manufacturing or engineering application.

Future of 5-axis CNC Milling

As with most advanced technologies, the future of 5-axis CNC milling is likely to see continued evolution and innovation. In recent years, there have been several developments that suggest a bright future for this technology.

One potential area of advancement is in the software used to control the 5-axis CNC machine. As computer technology continues to improve, software developers are finding new ways to improve the accuracy, speed, and efficiency of these machines. This includes the use of advanced algorithms, machine learning, and artificial intelligence to optimize the milling process and reduce errors.

Another potential area of advancement is in the hardware used in 5-axis CNC milling. For example, there has been an increase in the use of hybrid additive-subtractive manufacturing, where 3D printing technology is integrated with 5-axis CNC milling to create highly complex and intricate parts. This approach combines the benefits of both technologies, allowing for greater flexibility, precision, and speed.

Additionally, advancements in materials science are also likely to impact the future of 5-axis CNC milling. As new materials are developed that are more difficult to machine with traditional methods, 5-axis CNC milling machines will become even more important for the production of intricate parts and components.

The future of 5-axis CNC milling is likely to see continued evolution and innovation, driven by advancements in software, hardware, and materials science. As this technology becomes more advanced and sophisticated, it will continue to play a critical role in the manufacturing and engineering industries, enabling the production of highly complex and intricate parts with greater precision, speed, and efficiency.

Conclusion

5-axis CNC milling has become an essential technology in the manufacturing and engineering industries. With its ability to create complex and intricate cuts and contours with precision, accuracy, and efficiency, it has revolutionized the way that many industries produce parts and components. From aerospace and medical to automotive and mold and die making, 5-axis CNC milling has played a critical role in shaping the modern manufacturing industry.

In addition to its current importance, the future of 5-axis machining looks bright, with continued advancements and innovations likely to make this technology even more essential in the years to come. As computer technology, materials science, and hardware continue to evolve, 5-axis CNC machines will become even more sophisticated, efficient, and precise, enabling manufacturers to create increasingly complex and intricate parts with ease.

In conclusion, 5-axis machining has changed the way that we think about manufacturing, and it will continue to shape the industry for many years to come. Its importance cannot be overstated, and it will remain a critical technology for the production of high-quality parts and components.