Plastic Injection Molding Tolerances: How to Get the Best Precision

Injection molding is a very common way to make a wide variety of plastic products, parts, and components. The process involves melting plastic pellets and injecting the molten material into a mold cavity, where it solidifies and takes on the shape of the mold. The ability to achieve precise tolerances, which are necessary to guarantee consistent product quality, performance, and functionality, is one crucial aspect of injection molding.

The design and manufacturing of injection-molded parts require adherence to proper dimensions and tight tolerances to ensure optimal performance. Neglecting these aspects could result in underperformance or even failure of the part. Injection molding tolerances are particularly crucial for complex plastic injection-molded parts. Standard injection molding tolerances are around +/- 0.1 mm, while +/- 0.025 mm is achievable for very requirement injection molded parts.

Factors that influence the tolerances and optimize injection molding tolerances

Shrinkage

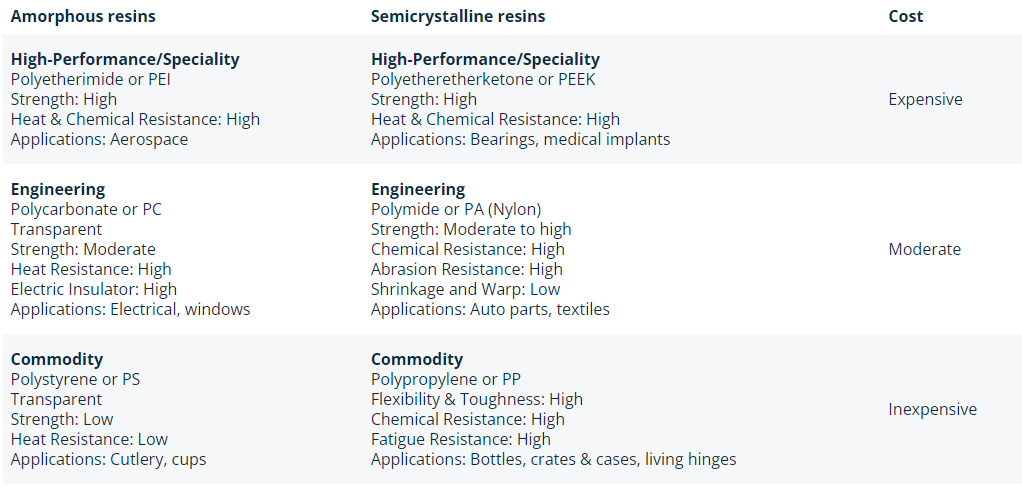

The degree of shrinkage varies among different materials, with higher shrinkage rates making it harder to achieve precise injection molding tolerances. Amorphous materials like PE, PC, and PS generally have better injection molding tolerances than crystalline materials like PEEK, PA, and PP. This is because when crystalline materials melt, they undergo a phase change from a tightly packed molecular structure to a less dense fluid structure, resulting in a change in volume and greater shrinkage. In contrast, amorphous materials remain in their non-crystalline state even when melted, causing less shrinkage.

How to reduce shrinkage’s influence

Injection molds are fabricated with high precision using CNC machining techniques on either aluminum or steel materials. They can maintain tolerances within the range of +/-0.01 if necessary. Once the plastic is injected into the mold, it undergoes a cooling process that causes it to shrink. The extent of shrinkage depends on the specific resin or plastic being used. To account for this shrinkage, each mold is made slightly larger than the desired final part size.

Applying plastic material with fiberglass or fiber carbon could dramatically reduce its shrink rate. For example, POM typically has a shrink rate of around 2~3%, and POM with 15% fiberglass only has a typical shrink rate of less than 0.5%.

Warpage

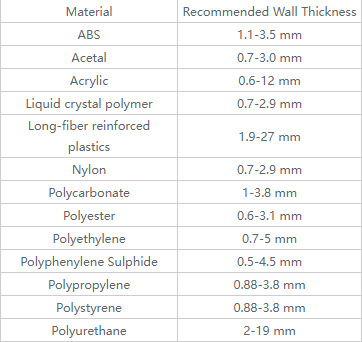

During the cooling phase in the injection molding, all parts will experience some degree of shrinkage. Parts that have uniform wall thickness will shrink evenly and are less likely to warp or have sink marks. However, if the walls are non-uniform, the cooling and shrinkage rates will vary, which can result in increased warping of the part due to inherent design issues.

Solution

To prevent warpage in parts with non-uniform wall thickness, it is advisable to limit the change in thickness to no more than 15% of the nominal wall thickness. Additionally, a smooth or tapered transition should always be employed to ensure the part is effectively molded. The following table provides recommended wall thicknesses to avoid warping:

Thermal expansion

The design phase must also take temperature into account. Maintaining tight tolerances with most resins and plastics can be difficult due to their high rates of thermal expansion. Even if injection molding parts can initially achieve tight tolerances under controlled conditions, it does not guarantee that they will maintain these dimensions over time or in response to temperature changes, such as those encountered when used outdoors in real-life conditions. This becomes especially crucial when plastic parts are combined with other materials, such as metals, and when the part is subjected to extreme temperature variations.

Solution

To ensure tight tolerances are maintained, it is important for engineers to select the appropriate injection molding material that can withstand the anticipated environmental and temperature conditions. Choosing the wrong material, which may respond unpredictably to such conditions, can compromise the ability to maintain tight tolerances.

It should be noted that plastics generally have significant thermal expansion coefficients. This means that tolerances may be different in a controlled environment versus real-world conditions where the parts are used. For instance, ULTEM and PEEK plastics are more resistant to high temperatures than ABS or PC.

Part design

Determining the tolerances of a part is primarily influenced by its design. Improving the design during the initial phases of a project not only helps to achieve good injection molding tolerances during production but also enhances quality and manufacturability, reduces costs, and enhances end-user satisfaction.

Various factors such as part geometry, overall size, and wall thickness requirements can all affect molding tolerances control. Thick walls, for instance, may have different shrink rates within the thick sections, making it difficult to maintain tight tolerances since the part shrinks differently at different sections. Similarly, the size of the part can impact the ability to maintain tight tolerances, particularly if the dimension with the tight tolerance is large. It is easier to maintain tight dimensional tolerances even in smaller areas, whereas larger dimensions may experience greater overall shrinkage, making it more challenging to control and maintain tight tolerances.

Solution

Early identification of tight tolerances in the design phase enables engineers to consider various factors that affect injection molding tolerances, including part geometry, size, and features like wall thickness. To maintain tight tolerances, it is important to ensure uniform wall thickness throughout the part to avoid uneven shrink rates that can cause deformities and reduce the part’s efficiency. In many cases, design features such as support ribs or gussets are more effective at providing strength than increasing wall thickness.

Part complexity

Part complexity also impacts material flow and tooling design because filling the parts quickly into the mold, maintaining proper tooling temperature, and cooling process management are important for tight molding tolerances.

Solution

Although the manufacturing process is typically more relevant to manufacturers, it is still important to consider it during the design stage. To avoid undercuts, it is recommended to keep the design as simple as possible. If an undercut is necessary, a mold with side actions should be designed. Properly designed mold tools are critical in ensuring that parts cool properly and meet strict tolerance standards.

Engineers can track and adjust variables such as injection pressure, resin viscosity, and mold fill time to ensure the right pressure, proper heating, and cooling during the process. Mold flow analysis is necessary for accurate predictions regarding factors influencing tolerances, such as mold temperatures, heating and cooling, shrinkage, and warpage.

Tooling

There are three types of tools in Injection molding:

Single cavity tool – Produces single part for a single shot of plastic

Multi-cavity tool – Produces multiple parts for a single shot of plastic

Family cavity tool – Produces all the parts of an assembly for a single shot of plastic

The ability to achieve desired tolerances in injection molding is affected by tool design, tool material, and cavitation. The number of cavities in a tool and the need for heating and cooling can make achieving tight tolerances more challenging. If the tooling design fails to provide consistent and repeatable cooling, shrink rates increase and result in poor tolerances. For instance, a multi-tool or family tool with more cavities requires more cooling support. Tight tolerances can be difficult to achieve if the tool cavities are poorly designed or influenced by factors such as pressure or temperature.

Solution

While this part may be more relevant for manufacturers, it is still important for designers to consider the impact of manufacturing processes on the viability and quality of their parts. Process controls are used to calibrate the many factors involved in the production to minimize deviations.

Temperature and pressure sensors integrated into the mold play a crucial role in developing effective process controls, providing real-time feedback on these parameters, and allowing for rapid adjustments to be made if necessary. By properly controlling these factors, the mold tooling can create parts with tight tolerances and minimal deviation. Moldfill analysis is also a useful tool for assessing the condition of the mold and ensuring consistent production.

Other considerations

Controlling process variables is crucial in manufacturing to ensure the quality and viability of parts. Real-time feedback from pressure and temperature sensors in mold tooling is essential to developing robust process controls.

This feedback allows for rapid adjustments to minimize variation and ensure repeatability. When process variables are controlled in a repeatable manner, the mold tooling can produce parts with precise tolerances and minimal variation, leading to higher-quality products.

Conclusion

In conclusion, achieving tight tolerances in plastic injection molding requires a comprehensive understanding of the interplay between several factors, including part design, material selection, tool design, and process control. By taking a holistic approach to the injection molding process, product teams can optimize part designs, refine materials and resins, and calibrate process controls to achieve precision and minimize deviation.

This not only results in high-quality parts but also helps to reduce costs, improve efficiency, and increase customer satisfaction. By applying the best practices outlined in this article, product teams can produce injection-molded parts with the highest level of accuracy and reliability.