Top 5 Most Commonly Used Materials in CNC Machining: Properties and Applications

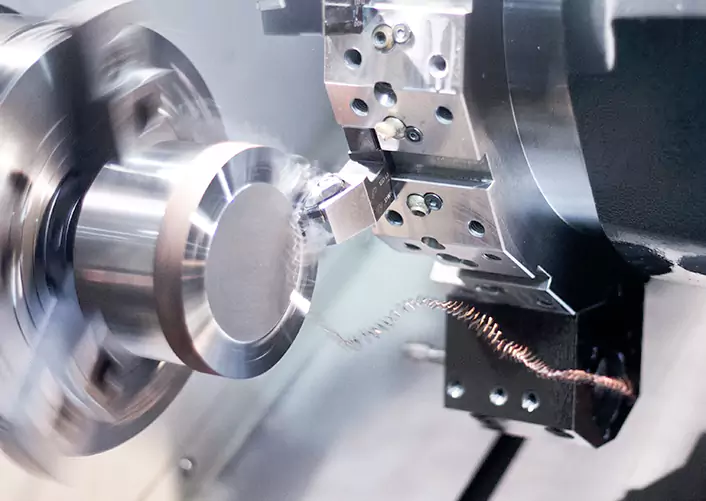

CNC machining has become a popular method for the fabrication of precision parts and components across various industries. However, the choice of CNC material plays a crucial role in determining the quality and performance of the finished product. This article aims to explore the 5 most common materials in CNC machining, their properties, applications, advantages, and disadvantages. Additionally, we will discuss the factors to consider when selecting the best material for CNC machining projects.

The Top 5 Most Commonly Used CNC Machining Materials

Aluminum alloys

When it comes to CNC machining, aluminum is a material that stands out due to its good mechanical properties. It is lightweight, yet strong and durable, making it ideal for various applications in different industries. Here are some key facts about aluminum CNC materials:

Properties of Aluminum

● Lightweight: Aluminum has a low density, making it an ideal material for applications that require a lightweight part.

● Strong: Despite its lightweight properties, aluminum is a strong material that can withstand high stresses and strains.

● Versatile: Aluminum can be easily machined into complex shapes and intricate designs.

● Corrosion-resistant: Aluminum has good corrosion resistance, making it suitable for use in outdoor or marine environments.

● High thermal conductivity: Aluminum’s thermal conductivity makes it useful for heat sinks and other thermal management applications.

Applications for Aluminum alloys

● Aerospace industry: Aluminum is commonly used in the aerospace industry for aircraft parts and components.

● Automotive industry: Aluminum is used for engine parts, wheels, and other components in the automotive industry.

● Consumer goods: Aluminum is used in the production of laptop cases, mobile phone frames, and bicycle frames.

● Medical industry: Aluminum is used for surgical instruments and equipment in the medical industry.

Advantages of Aluminum

● Easy to machine: Aluminum is easy to machine, which means it can be used to create complex shapes and intricate designs.

● High strength-to-weight ratio: Aluminum’s strength-to-weight ratio makes it an excellent choice for lightweight applications.

● Non-toxic: Aluminum is non-toxic, which makes it safe for use in medical applications.

Disadvantages of Aluminum

● Lower hardness level than some metals: Aluminum has a lower hardness level than some metals, which means it may not be suitable for high-wear applications.

● More expensive than other CNC materials: Aluminum alloys can be more expensive than other CNC machining materials, such as steel or brass.

Stainless Steels

Stainless Steel is one of the most common CNC materials. It is known for its durability, strength, and resistance to corrosion. It is made by adding at least 10.5% chromium to steel, which forms a thin protective layer on the surface of the material, preventing rust and corrosion. Here are some important facts about Stainless Steels in CNC machining:

Properties of Stainless Steel

● Corrosion-resistant: Stainless Steel is highly resistant to corrosion, making it ideal for use in harsh environments.

● High strength: Stainless Steel is a strong CNC material that can withstand high stresses and strains.

● Temperature resistant: Stainless Steel can maintain its strength and shape even at high temperatures, making it suitable for applications involving heat.

Applications for Stainless Steel

● Medical industry: Stainless Steel is a common material used for surgical instruments and medical equipment due to its wear resistance to corrosion and ease of sterilization.

● Aerospace industry: Stainless Steel is often used for aircraft components as it can withstand high temperatures and has high strength.

● Automotive industry: Stainless Steel is used for car exhaust systems, engines, and other CNC-machined components that require strength and resistance to corrosion.

● Consumer goods: Stainless Steel is used in the production of kitchen appliances, cutlery, and jewelry due to its corrosion resistance and attractive appearance.

Advantages of Stainless Steel

● Corrosion-resistant: Stainless Steel’s high level of corrosion resistance is its primary advantage, making it suitable for use in harsh environments.

● High strength: Stainless Steel is a strong material that can withstand high stresses and strains.

● Aesthetic appeal: Stainless Steel has an attractive appearance that makes it popular for use in consumer goods.

Disadvantages of Stainless Steel

● High cost: Stainless Steel can be more expensive than other common materials such as aluminum or plastic.

● Difficult to machine: Stainless Steel is a hard material to machine, which can make it more challenging to work with than other CNC machining materials.

Brass

Brass is a unique material that has excellent machinability and aesthetic appeal, making it a popular choice in CNC machining. With its durability and resistance to corrosion, it is a reliable option for various industrial applications such as marine and architecture. Here are some key facts about brass in CNC machining:

Properties of Brass

● Excellent machinability: Brass is known for its excellent machinability, which makes it easy to work with and allows for the creation of intricate designs.

● Corrosion-resistant: Brass has good corrosion resistance and can withstand exposure to water, making it suitable for use in marine environments.

● Durable: Brass is a highly durable material that can withstand high-stress environments and harsh conditions.

● Aesthetic appeal: Brass has a unique color and aesthetic appeal that makes it a popular choice for decorative parts and components.

Applications for Brass

● Decorative items: Brass is often used to create decorative items such as sculptures, vases, and jewelry.

● Musical instruments: Brass is commonly used in the production of musical instruments such as trumpets and trombones.

● Plumbing fixtures: Brass is a popular material for plumbing fixtures such as faucets and valves due to its corrosion resistance and durability.

● Electrical components: Brass is often used in electronic components such as connectors and switches.

Advantages of Brass

● Aesthetic appeal: Brass has a unique color and aesthetic appeal that makes it a popular choice for decorative parts and components.

● Excellent machinability: Brass is known for its excellent machinability, which makes it easy to work with and allows for the creation of intricate designs.

● Corrosion-resistant: Brass has good corrosion resistance and can withstand exposure to water, making it suitable for use in marine environments.

Disadvantages of Brass

● Limited strength: Brass has lower strength than other metals, such as steel, which means it may not be suitable for high-stress applications.

● High cost: Brass can be more expensive than certain materials, such as aluminum or plastics, which may make it less cost-effective for some applications.

Titanium

Titanium is a highly sought-after CNC material due to its exceptional properties. It is lightweight, yet strong and durable, making it ideal for aerospace, medical, and military applications. Its resistance to corrosion and high melting point also makes it an excellent choice for extreme environments. Here’s a breakdown of the key facts about titanium in CNC machining:

Properties of Titanium

● High strength-to-weight ratio: Titanium is an incredibly strong yet lightweight material, making it ideal for applications where strength is necessary without adding too much weight.

● Corrosion-resistant: Titanium is highly resistant to corrosion and is suitable for use in harsh environments, such as marine applications.

● Biocompatible: Titanium is biocompatible, which makes it a popular material for medical implants and prosthetics.

● Heat resistance: Titanium has a high melting point and is resistant to heat, making it suitable for high-temperature applications.

Applications for Titanium

● Aerospace: Titanium is widely used in the aerospace industry, including for aircraft components such as landing gears, engine parts, and structural components.

● Medical: Titanium’s biocompatibility and strength make it an ideal material for medical implants, such as joint replacements and bone plates.

● Automotive: Titanium is used in automotive components, including exhaust systems, engine parts, and suspension parts, for its strength and lightweight properties.

Advantages of Titanium

● Lightweight: Titanium is a lightweight material, making it ideal for use in applications where weight is a concern.

● Exceptional strength: Titanium is incredibly strong, even stronger than steel, and has a high strength-to-weight ratio.

● Non-magnetic: Titanium is non-magnetic, making it suitable for use in electronic equipment.

● High-temperature resistance: Titanium is resistant to fire and heat, making it ideal for high-temperature applications.

Disadvantages of Titanium

● Expensive: Titanium is an expensive material due to its high cost of production and difficulty in extraction.

● Challenging machining: Titanium is a challenging material to machine, requiring specialized tools and techniques.

Plastics

Plastics are a versatile and affordable option for CNC machining projects, as they can be molded into complex shapes and offer excellent chemical resistance. From automotive parts to medical devices, plastic materials are used in a wide range of industries due to their durability and ease of manufacturing. Here are the key facts about plastic CNC materials:

Properties of Plastics

● Versatility: Plastic materials are available in a wide range of types, each with its unique properties, such as flexibility, rigidity, and transparency.

● Affordability: Compared to metals, plastics are generally less expensive, making them a cost-efficient material choice for many applications.

● Moldability: Plastics can be easily molded into complex shapes, making them ideal for intricate components and parts.

● Chemical resistance: Plastics are often resistant to chemicals and can withstand exposure to various substances.

Applications for Plastics

● Consumer products: Plastics are widely used in consumer products such as toys, electronics, and household appliances.

● Automotive: Plastics are used in automotive components such as dashboards, bumpers, and interior trim due to their lightweight and impact-resistance properties.

● Medical: Plastics are used in medical devices such as syringes, implants, and tubing due to their biocompatibility and ability to withstand sterilization.

● Packaging: Plastics are widely used in packaging materials such as bottles, containers, and bags due to their low cost and ease of manufacturing.

Advantages of Plastics

● Versatility: Plastics can be molded into a variety of shapes and sizes, making them highly versatile materials for CNC machining.

● Affordability: Plastics are often more cost-effective than other materials, making them a popular choice for CNC machining projects.

● Chemical resistance: Plastics are highly resistant to many chemicals, making them ideal for use in corrosive environments.

Disadvantages of Plastics

● Limited strength: Plastics are not as strong as metals and may not be suitable for applications requiring high strength.

● Low heat resistance: Plastics have low heat resistance and can melt or deform at high temperatures.

● Environmental concerns: Some CNC plastics are not biodegradable and can contribute to environmental pollution if not properly disposed of.

How to Choose the Right CNC Materials for Your Machining Project

When choosing CNC materials for a machining project, several factors need to be considered to ensure optimal performance, cost-effectiveness, and compatibility. Here are the key factors to consider:

Properties that affect machining performance

● Machinability: The material’s machinability is an essential consideration, as it can affect the ease and speed of the CNC manufacturing process. A material with good machinability can help reduce machining time, labor costs, and tool wear.

● Tensile strength: The material’s tensile strength determines its resistance to breaking or deforming under stress. High-strength materials are more durable but may be more challenging to machine.

● Hardness: The material’s hardness affects the wear and tear on cutting tools during the machining process. Harder materials may require more robust tools and cutting parameters to achieve the desired outcome.

● Ductility: Ductility refers to the material’s ability to bend and stretch without breaking. Materials with high ductility can be challenging to the machine as they can deform or gum up cutting tools.

Cost considerations

● Material cost: The cost of the material itself is a significant consideration when selecting materials for CNC machining. High-end materials may offer superior properties, but they may not be cost-effective for certain applications.

● Machining cost: The material’s machinability also affects the machining cost. Materials that are difficult to machine may require more labor and time, leading to higher costs.

Availability of materials

● Material availability: Some materials may be challenging to source, which can impact the production timeline and increase costs. It is essential to consider the availability of materials when choosing materials for CNC machining.

Material compatibility with other components or parts

● Material compatibility: The applied materials for CNC manufacturing must be compatible with other components or parts used in the assembly. Material compatibility ensures that the final product meets the required specifications and performs as intended.

Overall, selecting the right material for CNC machining requires considering several factors, including the material properties that affect machining performance, cost considerations, availability of materials, and compatibility with other components or parts. By evaluating these factors, manufacturers can choose the right materials that offer optimal performance, cost-effectiveness, and compatibility for their CNC machining project.

Final Thoughts

In conclusion, selecting the right material is essential to achieving the desired results in CNC machining. The top 5 CNC materials discussed in this article – aluminum, stainless steel, brass, titanium, and plastics – all have their own unique properties, applications, advantages, and disadvantages. When selecting a material for CNC machining, it is important to consider factors such as material properties that affect machining performance, cost considerations, availability of materials, and material compatibility with other components or parts. By carefully considering these factors, you can ensure that you select the right material for your CNC machining project and achieve the desired results.