Minimizing Defects in High Pressure Die Casting

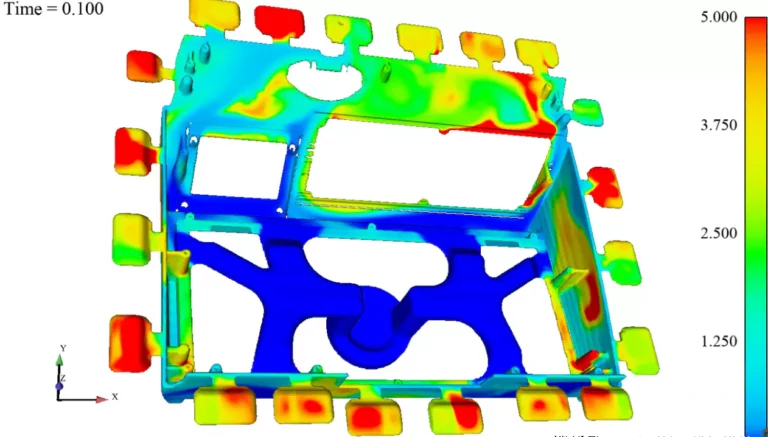

Simulation in HPDC 1. Overview of Simulation Software 2. Identifying Defects through Simulation 3. Optimizing Parameters to Minimize Defects Minimizing Defects 1. Improved Product Quality through Defect Minimization 2. Increased Efficiency through Simulation 3. Cost Savings through Simulation Obstacles and…