High-Pressure Die Casting: How Industry Does It

Have you ever been curious about the manufacturing process for complex vehicle parts such as engine blocks, powertrains, and suspension components? In contrast, lightweight tools used in the medical industry can be easily manufactured. High-pressure die casting (HPDC), which is a common way to make things, can make both kinds of products.

What makes HPDC so popular and versatile? This article gives a full explanation of the technical aspects of the die-casting process, as well as its many uses and benefits. Armed with this knowledge, you can make an informed decision about whether HPDC is the right manufacturing method for your needs.

What is High Pressure Die Casting?

The high-pressure die-casting process involves feeding molten metal into a die and allowing it to solidify to create the desired component. The molten metal is pushed into the die cavity under high pressure, typically with the aid of hydraulic pressure, and a robust press holds it in place. After solidification is complete, the die is opened to remove the casting. The die is then locked again for the next production cycle. The tooling for high-pressure die casting consists of two steel blocks that create the two ends of the die cavity, forming the desired object.

Evolution History of High-Pressure Die Casting

Die casting was first developed in the mid-1800s for the printing industry, where a mixture of lead and tin was poured into a steel mold to produce printing machinery keys. Over time, the process gained popularity in a wide range of industries. By utilizing different mold shapes, die casting could create a diverse range of products. Starting in 1914, the manufacturing process began to incorporate other materials like zinc and aluminum alloys, which are still commonly used in the industry today. Additionally, by the mid-1930s, most of the alloys currently used in the industry had become available.

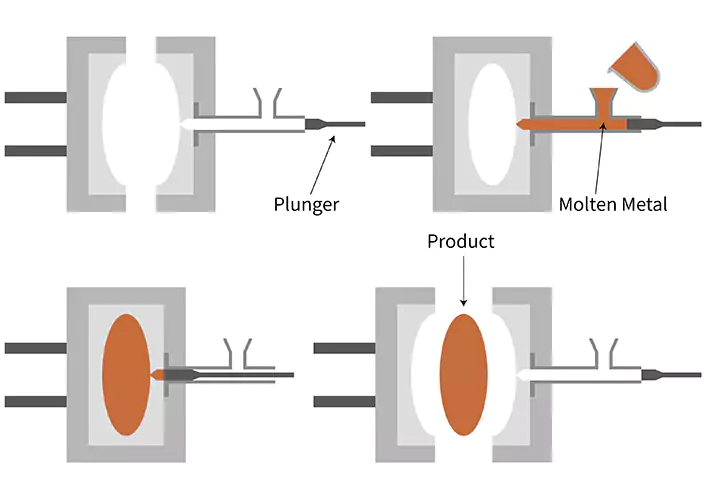

How Does High-Pressure Die Casting Work?

The typical operation of HPDC involves four stages, namely mold preparation, injection, ejection, and post-casting treatment. Adaptations to suit specific product requirements can result in techniques such as vacuum die casting, slow-fill die casting, and semisolid metal processing (SSM). Nevertheless, the fundamental procedural sequence remains as follows:

Mold Preparation

To commence the production cycle, it is essential to cleanse the die-cast mold of any impurities and apply lubrication to its interior walls. This process regulates the mold’s temperature and facilitates the effortless extraction of the casted product.

Injection

The molten metal is poured into a shot chamber and subsequently injected into the mold, which can be achieved via two methods: hot chamber and cold chamber injection.

Hot Chamber Injection

The immersion method involves submerging the injection system into the melting furnace, where the molten metal flows through the shot plunger and nozzle before entering the die. This technique is ideal for metals such as zinc, magnesium, and lead.

Cold Chamber Injection

The cold chamber method involves manually or automatically pouring molten metal into a cold chamber sleeve, followed by the use of a hydraulic plunger to force the metal into the die after sealing the port. Once solidification is complete, the plunger is removed, and the die is opened to eject the cavity. This approach is best suited for solid materials with high melting points, such as aluminum, brass, and magnesium. The cold chamber process can utilize either horizontal or vertical injection.

Magnesium can work with both cold chamber and hot chamber injection processes. Typically, hot chamber machines are used for small and intricate parts due to their size restrictions. Furthermore, high-pressure zinc die-casting parts are generally stronger than aluminum-pressure die-casting parts.

In both methods, the injection process takes place rapidly and at high pressures, typically ranging from 1,500 to 25,000 PSI. The mold must be entirely sealed and maintained under high pressure to facilitate solidification. Hydraulic pressures are utilized to compress any gases trapped within the mold and compensate for the solidification shrinkage during the cooling process. Commercially available forces of up to 4000 tons are sufficient to secure the die and withstand the high pressures.

Part Removal

Once it is confirmed that the molten metal has solidified, the cavity can be removed from the mold. This is achieved by using ejector pins, which are usually located on the movable end of the mold and push the solidified casting out of the cavity.

Trimming

The last stage of high-pressure die casting entails removing any excess material from both the product and the mold. The trimming process can involve the use of tools such as a trim die or saw. Additionally, any metal scraps generated during production can be recycled and reused in subsequent cycles.

If you are interested in learning more about die casting, our guide on low-pressure die casting can be a valuable resource to expand your knowledge.

Advantages of High Pressure Die Casting

High-pressure die casting is a popular process in various industries due to its several benefits relative to other manufacturing processes. Below are some of the advantages.

Higher Production Rates

Compared to low-pressure or gravity casting, high-pressure casting processes result in higher production rates. The use of high pressure allows for the injection of molten metal at high speeds, resulting in faster production times. As a result, this approach is popular in high-volume manufacturing.

Good Quality Parts Manufactured

In addition, high-pressure casting offers excellent quality in terms of dimensional accuracy and superior surface finish. The high-precision products produced through this method typically do not require extra trimming processes, which can be both time-consuming and costly. The smooth surface finish also simplifies the plating process. Additionally, high-pressure die-casting products offer advantages such as excellent uniformity and optimal mechanical properties.

Thin Wall Products

The high pressures used in this die-casting process enable the creation of thinner cross-sections compared to other casting methods. It is possible to achieve wall thicknesses of less than 0.40 mm, depending on the size and requirements of the component. These thin walls can help reduce the weight of the final product. Additionally, the thin walls allow for the inclusion of inserts (also known as “co-cast” parts), such as screws and liners, within the product during the casting process. This reduces the number of components needed during assembly.

Achieve Complex Design

The die-casting process offers the ability to use various die shapes, providing flexibility in the production of complex parts. This allows for creating of intricate components that can aid in complex assemblies.

Durable Dies

The dies utilized in the process have a long lifespan, making them suitable for reuse in multiple production cycles. This helps to reduce the per-unit cost of the die-casting product.

Applications of High-Pressure Die Casting

Due to the superior quality of products obtained through HPDC, the process has found various critical applications in a diverse set of industries.

Automotive Industry

High-pressure die casting is suitable for manufacturing a range of automotive structural components made of aluminum and magnesium. These components include engine blocks, gearbox casings, oil sumps, engine mounts, and cross-car beams, among others.

Medical Industry

The HPDC process is also widely used in the medical industry for producing lightweight surgical tools. In addition, it is utilized for the manufacturing of medical devices such as infusion pumps and high-production imaging equipment.

Aerospace Industry

The aerospace industry widely uses the HPDC process due to its capacity to produce intricate designs and automation. Alloys of aluminum, zinc, and magnesium are commonly utilized to manufacture engine components for aerospace applications.

FAQS

Q1. Why is it called die-casting?

The high-pressure die-casting process utilizes dies, which are typically made of steel and manufactured through CNC machining. These dies are used as molds into which liquid metal is injected. The die is split into two halves: a fixed half that is attached to the casting machine and a movable ejector half.

Q2. How does die casting differs from other casting production methods?

The benefits of die castings overlap with those of gravity-cast products. They share similar advantages such as the solidity, aesthetics, and texture of the metal, as well as proven fatigue strength and effective sound-dampening qualities. Additionally, die casting provides fast production rates with exceptional dimensional accuracy, often obviating the need for further machining. In contrast, sand casting necessitates a new mold for every production, while permanent mold casting is comparatively slower than high-pressure die casting (HPDC).

Q3. What is the difference between low-pressure and high-pressure die casting?

Low-pressure die casting (LPDC) operates within a pressure range of 0.08-0.15 MPa, whereas high-pressure die casting (HPDC) operates within a much higher range of 30-70 MPa. LPDC has a moderate production rate and a slow casting cycle, while HPDC boasts faster production rates and quicker casting cycles. HPDC typically produces products with some level of porosity but a high-quality surface finish. Meanwhile, LPDC produces castings without porosity, but the surface finish is average.