Investment Casting vs Die Casting

Casting is a process that involves pouring molten metal into a mold to achieve specific dimensions. There are two primary types of casting: investment casting and die casting. Based on their pros and cons, these methods are used to make different kinds of products. In what ways does investment casting differ from die casting?

Investment Casting

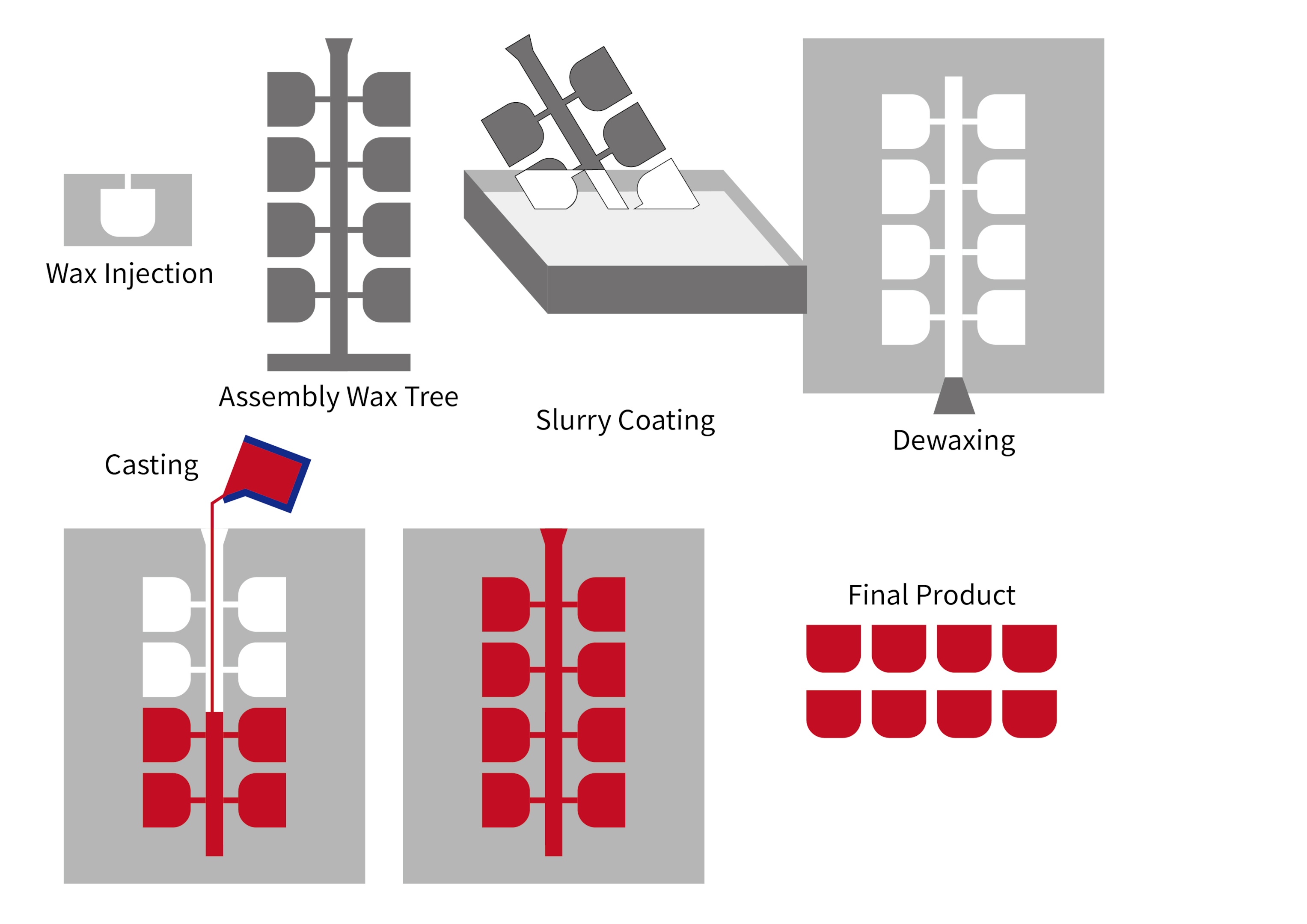

Investment casting, also known as precision or lost wax casting, involves several steps. First, a wax pattern is created in the desired shape of the component. This pattern is then attached to a sprue to form an assembly. The assembly is then dipped into liquid ceramic to create a protective layer, and the wax is removed by heating it in an oven. The shell is then filled with liquid metal and cooled to room temperature before the shell is cut to obtain the solid-shaped components.

Steps of the Investment Casting Process

Investment casting, also known as precision casting or lost-wax casting, typically involves the following process steps:

Creating the Wax Pattern

A wax pattern is created in the desired shape of the final component. This can be done by hand or using a machine.

Assembly

The wax pattern is then attached to a sprue to form an assembly tree. Multiple wax patterns can be assembled onto a single sprue.

Ceramic Dipping

The assembly is dipped into a ceramic slurry to create a ceramic shell. This shell will act as a mold for the molten metal.

Wax Removal

The ceramic shell is then heated in an oven to harden the ceramic and melt away the wax pattern, leaving a cavity in the ceramic shell in the shape of the pattern.

Metal Filling

The ceramic shell is filled with molten metal, typically by pouring the metal into the cavity through the sprue. The metal is allowed to cool and solidify.

Cutting the Shell

Once the metal has cooled and solidified, the ceramic shell is broken away, revealing the casting with the individual parts still attached.

Finishing

The individual parts are then separated from the casting and any excess material is removed. Depending on the desired finish, the parts may require additional machining, polishing, or other finishing processes.

Advantages of Investment Casting

Investment casting has several advantages, including:

Suitable for Complex Designs

Investment casting is well-suited for producing complex parts with intricate shapes, fine details, and thin walls. This is because the wax pattern can be easily manipulated to create virtually any shape or form.

Zero Draft Angles

Investment casting can produce parts with zero draft angles, which is the angle between the part and the direction of the mold release. This means that even parts with vertical or undercut surfaces can be produced without the need for complicated tooling.

Lower Tooling Cost for Lower Volumes

Investment casting is generally less expensive than other casting processes when producing lower volumes of parts, as the tooling costs are lower. This makes it a cost-effective option for producing small quantities of parts.

Excellent Surface Finish

Investment casting can produce parts with a smooth surface finish and tight dimensional tolerances, which can eliminate the need for additional machining or finishing operations.

Versatile Material Options

Investment casting can be used with a wide range of materials, including steel, aluminum, brass, and bronze, allowing for greater flexibility in part design and material selection.

Disadvantages of Investment Casting

While investment casting has many advantages, there are also some potential disadvantages to consider, including:

Higher Tooling Costs for High volume Projects

Investment casting can be more expensive than other casting processes for larger production runs, as the cost of tooling can be higher. The creation of wax patterns and ceramic molds can also be time-consuming and labor-intensive, which can add to the cost.

Limited to Simple Shapes

Although investment casting is well-suited for producing complex parts, it is limited to simpler shapes in comparison to some other casting processes. This is because the wax pattern can only be manipulated to a certain extent before it becomes too fragile and complex to handle.

Longer Lead Time

The investment casting process typically takes longer than other casting processes, as the creation of the wax patterns, ceramic molds, and casting of the metal all take time. This can result in longer lead times for the production of parts.

Porosity

Investment casting can sometimes result in parts with porosity, which are tiny voids or holes in the metal. This can weaken the part or cause it to fail under stress.

Material Limitations

Investment casting may not be suitable for certain materials, such as those with high melting points or those that are difficult to cast, which can limit the range of materials that can be used for parts.

Investment casting is a highly precise and versatile process, but it does have some limitations and potential drawbacks that need to be considered in the design and production process.

Die Casting

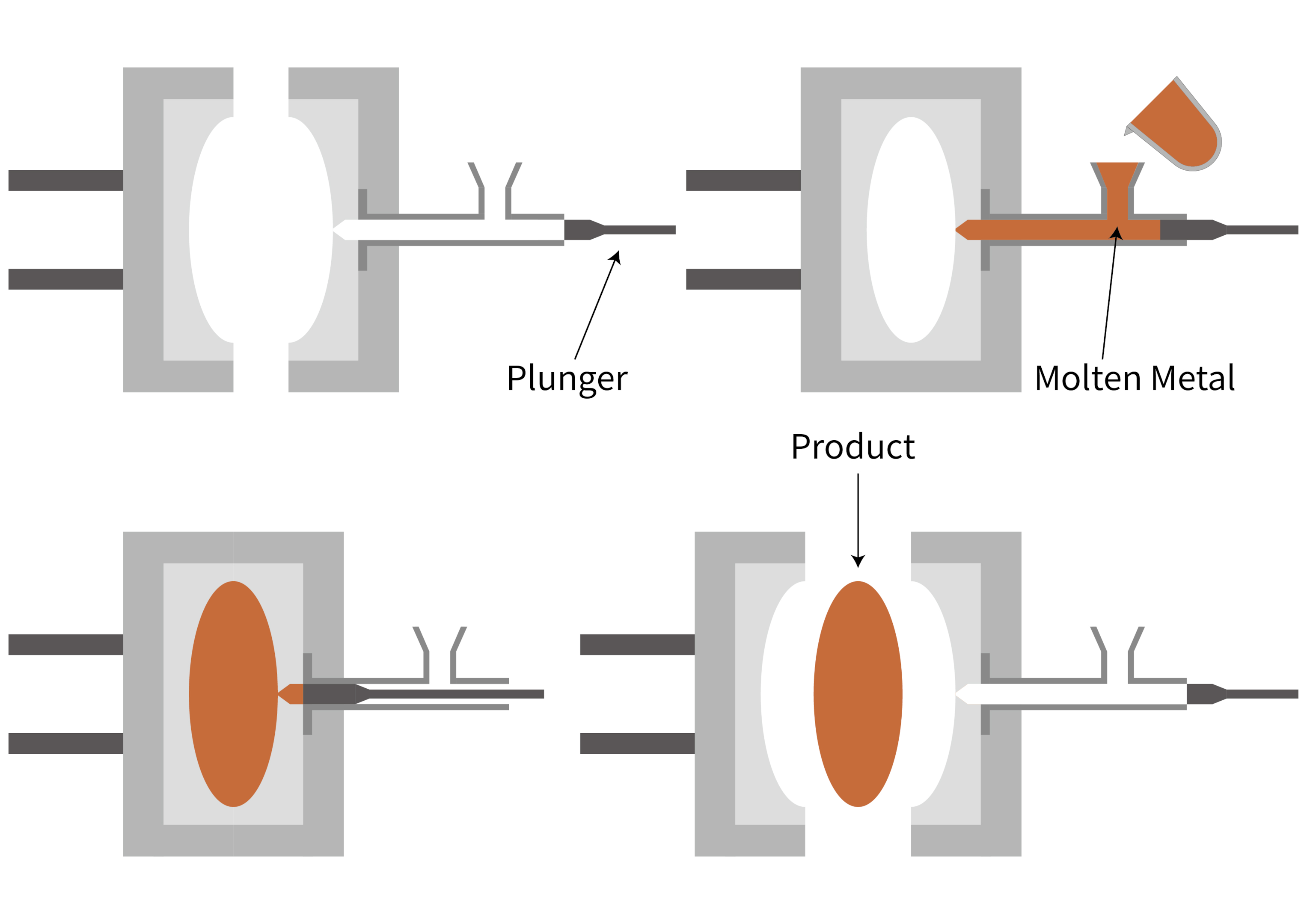

Die casting involves the use of high pressure to force molten metal into a die cavity. The caster creates a die using hardened tool steel in the shape of the desired parts. A release agent is applied to the die, and a barrel is filled with molten metal that is then pushed into the die cavities with a piston. The piston maintains pressure on the metal as it fills the die, and once the metal cools sufficiently, the casting is removed from the die and the individual parts are trimmed off. Finally, each part is machined as required to finish it.

Steps of Die Casting Process

Die casting typically involves the following process steps:

Creating the Die

A die is created with hardened tool steel in the shape of the desired parts. The die may contain multiple cavities for producing multiple parts simultaneously.

Applying Release Agent

A release agent is applied to the die to prevent the molten metal from sticking to the steel during the casting process.

Filling Molten Metal

A barrel is filled with molten metal, which is then pushed into the die cavities with a piston. The piston applies pressure to the metal as it fills the die.

Applying Pressure

Once the molten metal has filled the die cavity, pressure is applied to the metal to ensure that it fills all the intricate details of the die cavity and solidifies quickly.

Removing the product

Once the metal has cooled and solidified, the casting product is removed from the die.

Trimming Parts

The individual parts are then separated from the casting and any excess material is removed.

Finishing

Depending on the desired finish, the parts may require additional machining, polishing, or other finishing processes.

Advantages of Die Casting

Die casting has many advantages, including:

Consistent Repeatability

Die casting provides high dimensional accuracy and consistency in producing identical parts in large quantities. This is because the process relies on the use of hardened steel dies that can be precisely machined to produce parts with tight tolerances.

Suitable for Large Production Runs

Die casting is well-suited for large-scale production runs because it can produce a high volume of parts quickly and efficiently. This makes it an ideal process for manufacturing casting parts for the automotive, aerospace, and consumer goods industries.

Cost-Effective

Die casting can be a cost-effective option for large production runs, as the high initial tooling cost is offset by the ability to produce a large volume of parts at a low unit cost.

Disadvantages of Die Casting

While die casting offers many advantages, it also has some disadvantages, including:

Higher Tooling Cost

The initial cost of tooling for die casting can be quite high, which can make it less cost-effective for smaller production runs. The cost of tooling is largely due to the precision required in machining the dies and the hard steel used to resist the high-pressured metal flow.

Limited to Simple Shapes

Die casting is generally best suited for simple shapes with consistent wall thicknesses. Complex shapes can be challenging to die casting process, as the high pressures involved in the process can cause defects in the casting.

Brittle Parts

Parts made using die casting can be more brittle than those made using other casting methods. This is because the high pressures involved in the process can introduce small defects in the die-cast parts, which can weaken the part over time.

Limited Material Selection

Die casting is typically limited to non-ferrous metals such as aluminum, magnesium, and zinc. This limits the range of materials that can be used in the manufacturing process.

Investment Casting vs Die Casting

Design Complexity

Investment casting allows for greater design flexibility, enabling the casting of complex shapes with precise dimensions, intricate geometries, and thin-walled parts. Although die casting can also achieve precise dimensional results, it cannot produce designs as complex as those achievable through investment casting.

Material Selection

Investment casting offers a wider range of material options as both ferrous and non-ferrous alloys can be used. On the other hand, die casting is mainly adapted for materials such as aluminum, zinc, and magnesium alloys.

Part Size

Investment casting has size limitations due to the need to safely attach the wax model to the sprue and repeatedly dip it in the ceramic slurry. In contrast, die casting has fewer size limitations and can create larger components, but it incurs higher tooling and unit costs for larger products. The die-cast parts’ size is limited by the clamping force that casting equipment can create.

Cost

Investment casting is a labor-intensive process that results in superior dimensions and a good surface finish, making it a relatively high-cost casting method. However, it can potentially reduce or eliminate the need for secondary machining, saving both time and money. Die casting, on the other hand, incurs higher tooling costs and sometimes requires post-machining operations for finished components, making it more cost-effective for large order quantities.

Conclusion

In conclusion, both investment casting and die casting have their advantages and disadvantages. Investment casting offers greater design flexibility and material selection and is well-suited for complex shapes and smaller production runs. Die casting is better suited for larger production runs and has fewer size restrictions, but is limited to simpler shapes and materials. The choice between investment casting and die casting ultimately depends on the specific requirements of the project, including design complexity, material selection, part size, and cost considerations.