How to Avoid 5 Common Plastic Injection molding parts Defects

Plastic injection molding is a manufacturing process that involves melting plastic pellets and injecting the molten plastic into a mold cavity. The molten plastic is injected under high pressure into the mold cavity, which is designed to produce a specific shape or form.

Once the plastic cools and solidifies, the mold is opened, and the finished plastic part is ejected from the mold. This process is often used to mass-produce plastic parts with high precision, consistency, and accuracy. It is commonly used in the automotive, consumer goods, medical, and packaging industries.

Applications of Plastic Injection Molding

Plastic injection molding has a wide range of applications across various industries. Some of the most common applications of plastic injection molding include:

Automotive Industry

Plastic injection molding is widely used in the automotive industry for producing parts such as dashboard components, handles, knobs, and engine parts.

Medical Industry

The medical industry relies heavily on plastic injection molding for producing medical devices and components such as syringes, catheters, and medical implants.

Consumer Goods

Plastic injection molding is used to produce a variety of consumer goods such as toys, kitchenware, packaging, and electronic components.

Aerospace Industry

The aerospace industry uses plastic injection molding for producing parts such as ducting, housings, and brackets.

Construction Industry

Plastic injection molding is used in the construction industry for producing components such as pipes, valves, and fittings.

Overall, plastic injection molding is a versatile manufacturing process that can be used to produce a wide range of high-quality, low-cost parts and components for various industries.

Defects in Injection Molding

Defects in plastic injection molding can slow down the product development process and increase costs. If left unaddressed, they may also lead to a shorter lifespan of the final product. These issues can arise due to a variety of factors, such as design flaws, errors during the production process, or failures in quality control.

To minimize the risk of defects, it’s essential to take a proactive approach to risk mitigation throughout the product development cycle. In this article, we will discuss some of the most prevalent defects that can occur during plastic injection molding, and provide tips on how product teams can prevent them.

Flashing

Flashing refers to plastic material that leaks out of the injection mold during the molding process. This typically occurs at the edges where the mold halves meet, as well as around ejector pin locations. Insufficient pressure to hold the mold halves together is the primary cause of flashing.

How to Avoid

To minimize or prevent flashing during the injection molding process, increasing the holding pressure of the mold halves can be an effective solution. However, if this does not completely resolve the issue, it may indicate that the mold halves have sustained damage or have worn down over time, allowing flashing to occur. In such cases, it may be necessary to update the mold to correct any areas of high wear before creating a replacement mold.

Flashing can also be affected by several operational parameters, such as injection speed, mold temperatures, injection pressure, and venting. Therefore, investigating these factors and identifying any physical mold areas that contribute to flashing can help to limit or prevent it.

Weld lines

Knit lines, also known as meld lines, are defects that occur at the points where two streams of molten resin meet as they flow through the mold’s geometry. These defects are typically found in areas of the mold with holes. When the molten plastic material flows around each side of a hole, the two streams of plastic meet. If the temperature of the material is not optimal, the two streams may not properly bond together, resulting in a visible weld line. This can weaken the component’s overall strength and durability.

How to Avoid

To prevent premature solidification of the molten resin and reduce the likelihood of weld lines in injection molding, several approaches can be employed. These include raising the temperature of the molten resin, increasing the injection speed and pressure, and using resins with lower viscosity and melting points. Additionally, removing partitions from the mold design can help eliminate the formation of weld lines.

Burn Marks

Burn marks on injection molded components are the result of overheating the resin against the interior mold surface. These marks do not have a specific color and can appear as dark or rusty-colored spots. The spots are a degradation of the resin that can occur due to overheating or injection speed beyond the recommended limit for the particular resin being used.

High injection speed can also cause gas to become trapped inside the mold during the injection process, which can result in the burning or degradation of the resin and the formation of burn marks.

How to Avoid

To eliminate burn marks in injection molding, the parameters causing resin degradation should be adjusted. This is typically achieved by modifying the injection speed and/or temperature. Molds are typically designed with sufficient venting to release trapped gases. However, in rare cases, additional venting may need to be added to further reduce pressure trapped inside the mold and prevent the formation of burn marks.

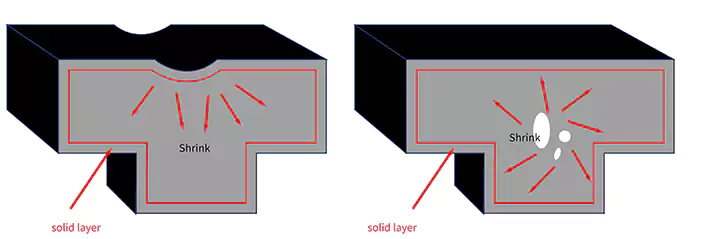

Sink Marks & Void

When the molten plastic is injected into the mold, due to the low surface temperature of the mold, the part of the molten plastic close to the mold wall will cool and solidify first. The part near the center will cool and solidify afterward. When the center part cools, it will shrink.

If the first solidified outer layer is strong enough, the plastic in the center will shrink toward the outer layer, forming a void. If the outer layer is not strong enough, the outer layer will shrink inward, forming Sink Marks. Sink marks are characterized by depressions, dents, or craters that occur in the thicker sections of a part. A void can not be observed in the final product, but it does weaken the product’s strength.

How to Avoid

Sink marks and voids are often a sign that the plastic needs more time to properly cool and cure inside the mold. One solution to this problem is to reduce the thickness of the thickest wall sections, which ensures more even and thorough cooling. Insufficient pressure in the mold cavity or higher-than-desired temperatures at the gate can also contribute to the formation of sink marks.

To minimize the risk of sink marks, it’s essential to ensure proper injection molding rib thickness and wall thickness during the design stage. These measures not only reduce the likelihood of sink marks but also increase the overall strength of the part.

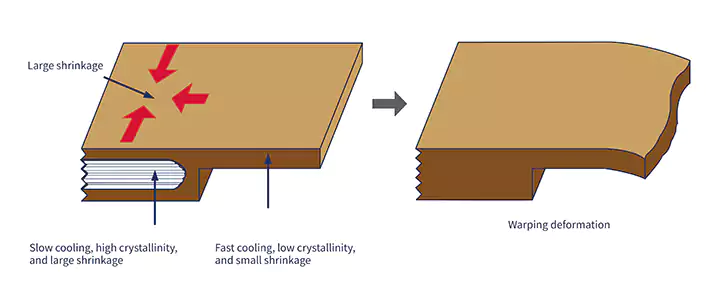

Warping

Warping in injection molding occurs when the product twists or bends due to uneven internal shrinkage during the cooling process. This defect is usually caused by inconsistent mold cooling, which creates internal stresses within the material.

How to Avoid

To avoid warping defects in plastic injection molding, it is important to allow enough time for the parts to cool at a gradual rate, which prevents internal stresses from developing and harming the part. Mold cooling must also be consistent and uniform to prevent any uneven shrinkage. The design of the mold should also feature uniform wall thickness to ensure consistent plastic flow through the mold cavity.

Importance of Identifying And Avoiding Defects

Identifying and avoiding defects in plastic injection molding is crucial to ensuring the quality, reliability, and safety of the final product. Defects can not only compromise the aesthetic appearance of the product but can also significantly weaken its structural integrity, resulting in a shorter lifespan and higher chances of failure. Additionally, defects can lead to delays in production, increased scrap rates, and higher production costs.

Choose CapableMachining to Succeed Your Injection Molding Project

When it comes to injection molding projects, choosing the right machining partner is crucial to ensure success. CapableMachining can make all the difference in the quality and efficiency of your project. We have a skilled machining team that can help you optimize your design for manufacturability, select the right plastic resin for injection molding, and ensure that your parts are produced to the highest standards. By working with CapableMachining, you can reduce lead times, minimize waste, and improve the overall quality of your parts. Contact us to start manufacturing your desired plastic parts.