Aluminum Alloys Used in Precision CNC Machining

What Are Alloys?

Alloys are metals mixed with other metals or non-metallic elements. For example, aluminum alloys, which are mostly aluminum and other elements like iron, copper, and magnesium, are often used in machining.

The machinability of different aluminum alloys is primarily determined by their composition, making certain alloys more appropriate for specific applications. It’s worth noting that the addition of other elements has a significant impact on an alloy’s physical properties, such as strength, ductility, and corrosion resistance. Hence, understanding these properties is crucial in determining the suitability of the material for a given part.

Aluminum alloys are classified into three groups: commercially pure aluminum, heat-treatable alloys, and non-heat-treatable alloys. While commercially pure aluminum is not commonly used in aluminum machining (although machine parts may use aluminum 1060), this article focuses on five alloys from the latter two groups.

Different Aluminum Alloys for CNC Machining

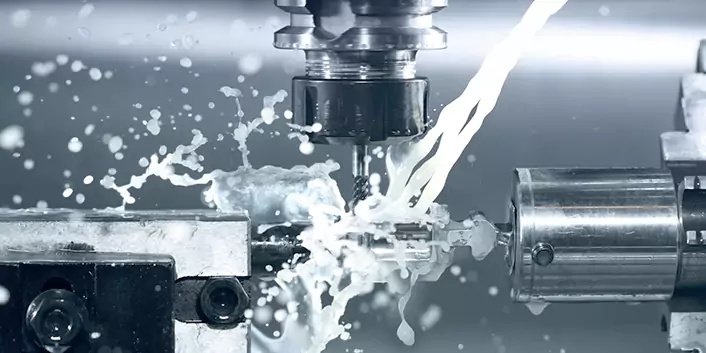

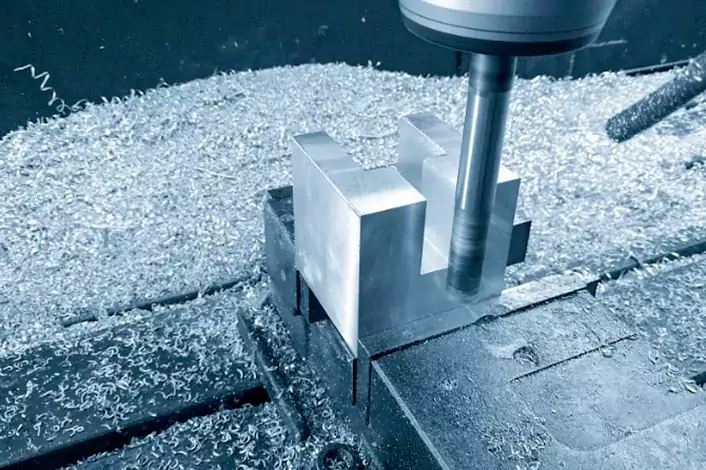

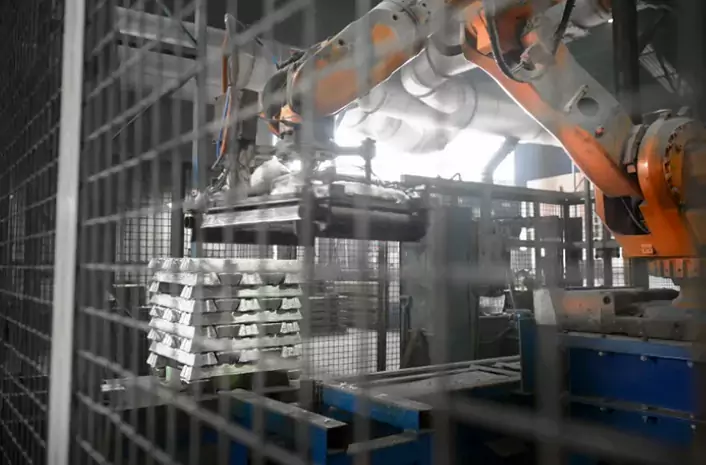

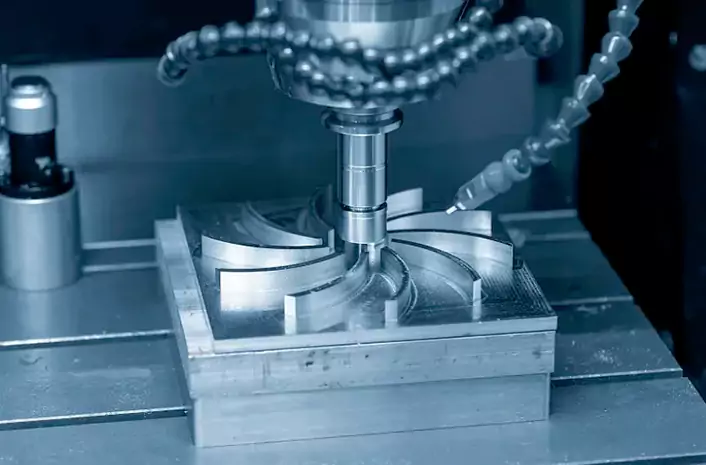

CNC machining involves the use of drills and turning tools to remove material from a solid block of material, creating a part. It’s a conventional manufacturing method that enables fast and highly precise production of parts with tight tolerances. This versatile process can be applied to a range of rigid materials, including plastics, metals, and fiberglass, with aluminum being a favored material for product development teams.

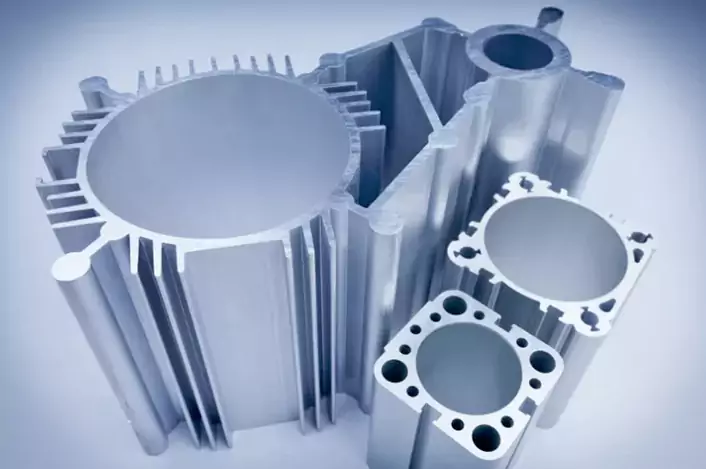

Although various metals can be machined using CNC machines, aluminum’s distinctive properties have made it a popular choice for CNC machining purposes. Aluminum alloy comes in different grades, and each aluminum alloy is best suited for specific applications.

Heat-Treatable Alloys

Heat-treatable alloys are comprised of a combination of metallic and non-metallic components, including pure aluminum that is heated to a specific temperature before alloying elements are added uniformly. This addition of alloying material causes the aluminum to solidify, albeit still at a high temperature, after which it is rapidly cooled through quenching. This rapid cooling can cause the atoms of the alloy elements to solidify in place.

Typically, heat-treatable aluminum alloys form as the aluminum atoms and alloy element atoms naturally combine during the aging process at room temperature. However, in some cases, this process is artificially induced through aging in a furnace set at a low temperature.

Aluminum 2024-T4

Aluminum 2024-T4 is a moderate- to high-strength alloy that offers good fatigue resistance and fracture toughness. It isn’t as strong as 7075-T6, but it’s still suitable for aerospace applications.

Common applications for aluminum 2024-T4 include aircraft fuselage, transport vehicle parts, and wing tension members. However, product teams should note that this grade of aluminum has poor corrosion resistance and is highly sensitive to thermal shock.

Mechanical specifications:

Ultimate tensile strength: 200 – 540 MPa

Elongation at break: 14 – 20%

Modulus of elasticity: 71 – 73.1 GPa

Hardness: 70 – 120 HB

Maximum service temperature: 200 °C

Aluminum 6061

The most commonly utilized aluminum grade in CNC machining is known for its exceptional processing capabilities, high toughness, good mechanical properties, good corrosion resistance, absence of deformation post-processing, easy color film formation, and excellent anodizing effects. It is one of the most common aluminum alloys used in the industry. This aluminum grade is used in various industries, including truck manufacturing, building construction, shipbuilding, tram manufacturing, furniture production, precision machining, and a broad range of industrial applications.

Mechanical specifications:

Tensile strength: 45,000 psi

Yield strength: 40,000 psi

Modulus of elasticity: 10,000,000 psi

Shear strength: 31,000 psi

Hardness: 95 Brinell

Density: 2.7 g/cm3

Melting point: 582°C (1080°F)

Thermal conductivity: 170 W/m-K

Coefficient of thermal expansion: 23.6 µm/m-K

Aluminum 6082

Aluminum 6082 boasts properties similar to aluminum 6061, with slightly higher tensile strength. It holds the distinction of having the highest strength among all the 6000 series alloys, in addition to excellent corrosion resistance. For engineers seeking greater strength than that provided by 6061 but not keen on investing in the 7000 series, 6082 is an attractive option.

This material is particularly well-suited for general-purpose applications that require increased strength and toughness, with widespread use in the construction industry in bridges, towers, and trusses. However, designers should note that it’s challenging to create thin walls using aluminum 6082.

Mechanical specifications:

Ultimate tensile strength: 140 – 340 MPa

Elongation at break: 6.3 – 18%

Modulus of elasticity: 69 – 71 GPa

Hardness: 35-56 HRB

Maximum service temperature: 130 – 150 °C

Aluminum MIC 6

MIC 6 Aluminum possesses a unique combination of alloy and casting methods, specifically designed to produce stable, high-tolerance plates. Its exceptional stress-relieving properties, accuracy, and machinability make it a highly sought-after option for machining components, electronics, and laser technology. Additionally, it is contaminant- and porosity-free, providing a smooth and lightweight choice.

However, compared to 6061 Aluminum, MIC 6 threads are not as strong, especially with fine threads that may result in premature thread failure. Therefore, designers should be mindful of this limitation during material selection.

Mechanical specifications:

Ultimate tensile strength: 166 MPa

Elongation at break: 3%

Modulus of elasticity: 71 GPa

Hardness: 65 HB

Maximum service temperature: 427 °C

Aluminum 7075

AA7075 is an aluminum alloy that contains zinc as its primary alloying element. This alloy possesses outstanding mechanical properties and demonstrates high ductility, toughness, and strength, along with good resistance to fatigue. Despite its susceptibility to embrittlement due to microsegregation, it has better corrosion resistance than alloys from the 2000 series. It has the strength same as mild steel but 1/3 of the weight. It is widely used in highly stressed structural applications, particularly in aircraft structural parts, making it one of the most frequently used aluminum alloys.

Mechanical specifications:

Tensile strength: 83,000 – 83,000 psi (570 – 570 MPa)

Yield strength: 73,000 – 73,000 psi (503 – 503 MPa)

Elongation at break: 11 – 11%

Modulus of elasticity: 10,200 – 10,200 ksi (70.3 – 70.3 GPa)

Shear modulus: 3,800 – 3,800 ksi (26.2 – 26.2 GPa)

Poisson’s ratio: 0.33 – 0.33

Fatigue strength: 47,000 – 47,000 psi (324 – 324 MPa) at 500 million cycles

Non-heat-treatable Alloys

Aluminum alloys that are not heat-treatable are created by combining aluminum with alloying elements prior to any heat treatment. The initial strength of these alloys is achieved through the addition of these elements. Non-heat-treatable alloys include pure aluminum alloys, manganese alloys, silicon alloys, and magnesium alloys. To further enhance the strength of these alloys, various cold-working and strain-hardening processes are utilized.

The most common methods of cold working and strain hardening involve rolling, drawing through dies, stretching, or other similar operations that result in an area reduction. The final properties of the alloy are determined by the total area reduction of the material. Additionally, “stabilizing” is a process carried out at elevated temperatures that ensures that the final mechanical properties of the alloy remain consistent over time.

Aluminum 3003

The 3003 aluminum alloy belongs to the wrought aluminum-manganese family, which is also known as the 3000 or 3xxx series. This type of alloy can be cold-worked to achieve tempers with increased strength but reduced ductility, as it cannot be heat-treated like some other aluminum alloys. Its properties are similar to those of other aluminum-manganese alloys, as it is a versatile alloy that possesses moderate strength, good workability, and excellent corrosion resistance. Although it can be rolled and extruded, it is not typically forged, and it is not suitable for casting due to its wrought nature. Sheet metal applications such as gutters, downspouts, roofing, and siding commonly use this alloy.

Mechanical specifications:

Tensile strength: 130-185 MPa (19,000-27,000 psi)

Yield strength: 55-115 MPa (8,000-17,000 psi)

Elongation: 10-30%

Hardness (Brinell): 40-60 HB

Aluminum 5052

Strong, workable, and corrosion-resistant, Aluminum 5052 — made with magnesium and chromium, amongst other components — is widely used in marine applications because of its resistance to saltwater. It is also the strongest non-heat-treatable alloy available. Aluminum 5052 sheets have enough strength for most applications while not too brittle to break when bending, they are probably the most common aluminum sheets used in sheet metal fabrications.

Mechanical specifications:

Tensile strength: 210-260 MPa (30,000 to 37,000 psi)

Yield strength: 160-200 MPa (23,000 to 29,000 psi)

Elongation: 12%-25%

Modulus of elasticity: 70.3 GPa (10,200 ksi)

Hardness: 60 Brinell

Fatigue strength: 110 MPa (16,000 psi) at 5×10^8 cycles

Conclusion

In conclusion, the wide range of aluminum alloys available for CNC machining provides engineers with a diverse set of options for different applications. The selection of an appropriate aluminum alloy depends on various factors such as strength, flexibility, corrosion resistance, and machinability, which are significantly influenced by the composition of the alloy. Therefore, understanding the properties of each alloy is crucial in selecting the ideal material for a given part. The commonly used aluminum alloys in CNC machining include heat-treatable alloys and non-heat-treatable alloys, with different physical and chemical properties. By taking into account the characteristics of each alloy, manufacturers can produce high-quality, efficient, and cost-effective machined parts for various industries.

I apologise, but, in my opinion, you are not right. I am assured. I can prove it.

Hi, you can submit your idea.

This rather valuable message

Unequivocally, excellent answer