Application and development trend of rapid tooling manufacturing

As people’s quality of life has improved, the demand for various products has increased, and replacement has become more and more frequent. The traditional mold manufacturing method can no longer meet the product processing standards well, and the emergence of rapid molds has responded to this requirement.

To ensure high-standard production of products, reduce unnecessary production waste, and control costs, it is indispensable to promote rapid molds. When carrying out mechanical manufacturing, especially for various large products, the quality of the finished product and the processing cost have a great impact.

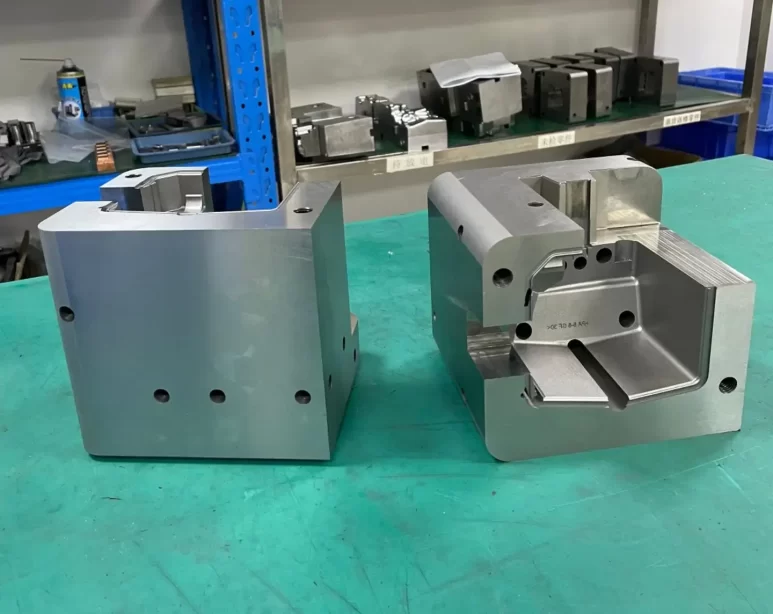

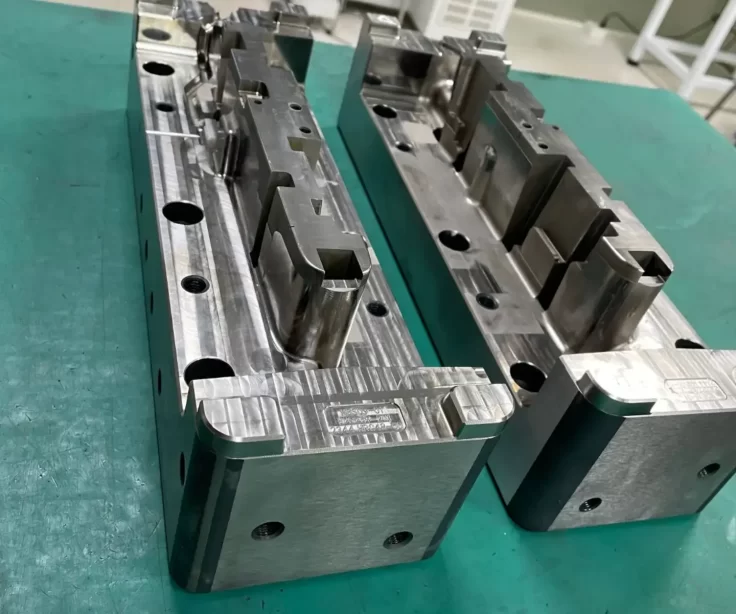

Mold manufacturing

Rapid prototyping is the basis of mold making. The quality of the final product is directly related to the technology, quality, performance, and process of mold manufacturing. It has an important impact on the production efficiency of end customers. Whether product research and development and production services can meet market needs is also a standard for measuring competitiveness in the field and a condition for expanding the advantages of the mid-to-high-end market.

Therefore, the new technology is incorporated into the design and process in the mold opening stage, and the accuracy and effectiveness of the product are ensured by standard calculations. Now some research institutions have comprehensively studied the theory of rapid prototyping technology, CAD information analysis software, casting mold automation-related principles, practical methods, and control systems, and have achieved good results in recent years.

Many technologies similar to SLA technology and LOM technology have been studied and integrated for application, and production casting has gradually improved and developed towards intelligence and automation.

The United States has developed rapid prototyping technology, and industrially developed countries such as the United Kingdom and Japan have gradually begun to upgrade the production of molds. The emergence of rapid prototyping technology just meets the development needs of this trend.

Based on using this technology, different types of methods are formed to upgrade the technology, complete the prototype manufacturing service or build the corresponding mold manufacturing process for users, and provide one-stop services for multiple specifications and production lines, so that all kinds of needs in the use process are fully guaranteed.

Rapid Tooling technology

Rapid mold manufacturing (abbreviated as RT) is a key technical method for faster and simpler production and processing or mold manufacturing based on the principle of rapid prototyping technology. It is a combination of traditional mold technology and modern advanced mold opening process technology. Mold opening is done by two methods: direct mold making and indirect mold making.

Each of these two categories has many different process methods. According to the requirements of product specifications, performance requirements, and precision requirements, appropriate technical methods can be selected. The method of rapid mold manufacturing technology of rapid prototyping technology generally adopts indirect mold making. Choose according to different product specifications, materials, and performance.

Rapid tooling Since the 20th century, rapid tooling manufacturing technology has been in a stage of continuous innovation and development. Its application fields are becoming more and more extensive. It is now widely used in many aspects such as machinery manufacturing, various light industrial products, medical equipment, civil engineering, and construction engineering. The continuous development and improvement of rapid tooling technology will become a method widely adopted by enterprise manufacturing.

Characteristics of Rapid Tooling

Material utilization is particularly important in modern industrial manufacturing. Reducing costs is the key. In production, the mold should reduce the structural waste and process waste of the workpiece as much as possible without affecting the quality of the workpiece.

RT can solve this problem well. By shortening the step distance of rapid tooling, structural waste can be reduced, and more workpieces can be punched out with the remaining process waste as much as possible, which will save a lot of materials and reduce costs for enterprises.

(I) Improved operability

To make it simple and easy for workers to operate, RT can greatly reduce the work intensity and reduce the probability of hidden finished product damage. In the design, it is necessary to avoid the flipping of the strip material and select a smaller strip material width to increase the mold life and ensure quality.

During the pattern arrangement process, the step distance cannot be designed to be too short, otherwise the workpieces will affect each other during punching, reducing the precision. At the same time, the step distance cannot be too small, otherwise, the strip material will be deformed, burrs will appear, and the quality of the finished product will be poor.

The traditional processing method is the “removal method”, that is, removing the excess metal layer on the blank and casting the required workpiece shape and precision according to the standard requirements.

Rapid manufacturing can prevent the process from causing wear and tear on the mold outside the workpiece and extend the service life of the mold.

(II) Improve the utilization rate of materials

Rapid manufacturing technology can be changed to waste pattern arrangement, less waste pattern arrangement, and no waste pattern arrangement. Waste pattern arrangement leaves a small amount of overlap on the periphery of the casting so that they will not affect each other during punching, ensuring the uniform precision of the casting and extending the service life.

Less waste pattern arrangement makes the width of the strip material stuck at the edge of the workpiece, and the casting only has overlaps in some parts. The size and precision are not easy to guarantee, but less waste is generated, which improves the utilization rate of materials.

No waste arrangement will not leave a margin at the edge of the strip between the workpieces, the size and workpiece accuracy cannot be guaranteed, the mold life is reduced, but very little waste is generated.

Rapid mold-making process

At present, the scope of use of rapid mold making is as follows: injection mold manufacturing, stamping mold manufacturing, casting mold manufacturing, etc. The methods used can be divided into indirect manufacturing and direct manufacturing. There are also three process flows:

One is the manufacturing of parts under small batch production mode;

The second is the manufacturing of parts under medium batch production mode;

The third is the manufacturing of parts under large batch production mode. There are direct and indirect methods for rapid mold making.

(I) Direct mold making method

The method of directly casting molds using rapid prototyping technology has high dimensional accuracy, short manufacturing time, delicate and flexible structure, and a very considerable development mold-making method. The material can be directly made into convex and concave molds using the SIS method, and can be made into simple casting plate molds and cover die-casting molds, which can make the service life of these molds reach one thousand years. It is very suitable for trial production products.

With the development of rapid prototyping technology, more and more mold materials can be used in rapid prototyping technology, and the performance of the materials is getting better and better, which can be used for mass production. However, the only shortcoming is that the precision of the products made by the mold is not high.

(II) Indirect molding method

The casting molds used in the indirect molding method are divided into soft molds, hard molds, and bridge molds. Soft molds are made of soft materials. The mechanical properties are adjusted by adjusting the material composition. They are suitable for small batch proofing. The manufacturing of hard molds is the cavity part of the metal mold. It is hardened by heat treatment and uses extremely high manufacturing technology. It has more stable myocardial infarction and competitiveness.

It is suitable for completing mass production. The price and subsequent processing of the two types are the same, but there are differences in processing procedures and production time.

Using the raw materials of rapid prototyping production technology as the master mold, combined with precision pressure casting, silicone rubber, powder sintering, and other processing methods, the model can be indirectly produced. The most important technology is to use rapid direct prototyping production technology to first make a metal mold core, and then use the mold core to copy the corresponding metal mold cavity of the product core.

Usually, a plaster mold or ceramic model is produced first, and then a metal model is cast from the plaster mold or ceramic model. Rapid indirect direct model production technology is the main direction of rapid model production at present.

Difficult

Although rapid molding has been widely used, it still has shortcomings, mainly the following problems:

- Although the rapid mold direct manufacturing method has a simple process and efficient production, it cannot meet the requirements of high precision and long mold life in terms of product size surface, precision quality, mechanical properties, and mold cost.

The most commonly used method for rapid mold direct manufacturing is to use selective laser sintering technology to make metal casting molds. The molds manufactured by this process are generally low-density porous structures. To improve performance, low-melting-point metals (such as copper) can be infiltrated to increase the precision of the mold. However, the strength of this type of mold is not high, and the precision is difficult to meet the requirements.

- Indirect mold rapid manufacturing is better than rapid mold direct manufacturing in many aspects and has the advantages of low casting process cost and fast manufacturing. However, rapid indirect mold manufacturing processes are generally more, which directly leads to great difficulty in controlling precision.

In general, the shrinkage size of mold materials manufactured by casting and powder sintering in indirect mold manufacturing varies greatly, and the manufacturing precision of the mold is not high.

The casting mold of the metal spraying mold has high dimensional accuracy, but it also has a small hole structure, which is difficult to spray, the density of the tissue coating is not enough, and the manufactured metal hard shell has great internal stress.

Solutions and Trends

(I) Use direct metal laser sintering technology

The direct method can use direct metal laser sintering technology or other methods to directly sinter metal powder, which can directly form stainless steel powder, nickel-based heat-resistant alloy, Tool steel, tungsten, titanium, and other materials.

Direct sintering of metal powder has low manufacturing cost, no processing and casting process before and after, higher processing precision, good surface quality of formed devices, and can be directly used as trial samples of products.

(II) Select high-performance materials

The solution for indirect manufacturing is to study a molding material with good dimensional stability and small shrinkage and to study and improve the process of indirect molding to reduce the number of processes and improve the accuracy of casting molds.

(III) Learn from traditional processing technology

The quality of casting molds produced by traditional mechanical processing technology is effectively guaranteed, the mold adaptation time is very long, and it is not easy to be damaged. With the continuous increase in market product competition, enterprises must be able to respond to changes in the market environment and customer needs at any time, so this kind of medium and small batch conversion method with high flexibility and strong mobility will be valued and used more and more widely.

Conclusion

It is difficult for molds manufactured by traditional mold technology and processes to meet market demand. Therefore, rapid prototyping can help the research of mold manufacturing, so that it can develop in the direction of high precision, long life, and high production efficiency in the future mold manufacturing field.