Benefits and Applications of CNC Machining

CNC machining is a computer-controlled manufacturing process that can create highly precise and intricate parts. It is used in a variety of industries such as aerospace, automotive and medical and offers several benefits, including increased accuracy, efficiency and productivity. CNC machining can be used to create a range of parts and products, from engine parts to medical implants and aircraft components. It is an essential part of modern manufacturing and will continue to be used in many industries in the future.

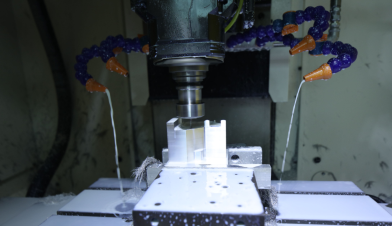

1. CNC machining is a computer-controlled manufacturing process that can create highly precise and intricate parts.

The use of Computer Numerical Control (CNC) machining has become increasingly important in manufacturing in the last few decades. CNC machining is a computer-controlled manufacturing process that uses programmed software to create highly precise and intricate parts. It is used in a variety of industries, including aerospace, automotive, and medical, to create a variety of parts and products.

CNC machining offers several important benefits. CNC machining has higher accuracy than traditional machining methods and can create parts with very intricate and complex shapes. It is also more efficient and productive than traditional machining, allowing manufacturers to produce parts faster. In addition, CNC machining can produce parts that are more consistent and reliable than traditional machining.

CNC machining can be used to create a variety of parts and products, from engine parts to medical implants and aircraft components. the machining also allows for more flexibility in product design, as it allows for changes to be easily incorporated into the design.

CNC machining is an essential part of modern manufacturing. Manufacturers rely on the process to create highly precise and intricate parts, and its use is expected to continue to grow in the coming years. CNC machining offers several advantages over traditional machining, and its use will continue to be important in a variety of industries.

2. CNC machining is used in a variety of industries, including aerospace, automotive, and medical.

CNC machining is a computer-controlled manufacturing process that is used in a variety of industries. It is ideal for creating highly precise and intricate parts, which is why it is used for producing parts for aerospace, automotive, and medical applications.

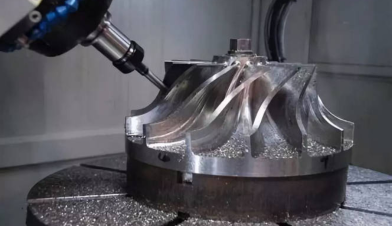

In the aerospace industry, it is used to create a variety of components, including engine parts, landing gear, and cabin interior components. This process is extremely accurate and can create components with high levels of accuracy and repeatability. Additionally, the processing allows for the production of parts with complex designs and can create components with intricate details.

In the automotive industry, CNC machining is used to create engine components, as well as a variety of other parts, such as wheels, bumpers, and spoilers. This process is extremely accurate and can create components with high levels of accuracy and repeatability. Additionally, CNC machining allows for the production of parts with complex designs and can create components with intricate details.

In the medical industry, the machining is used to create a variety of medical implants, including joint replacements and prosthetics. This process is extremely accurate and can create components with high levels of accuracy and repeatability. Additionally, the machining allows for the production of parts with complex designs and can create components with intricate details.

CNC machining is an essential part of modern manufacturing, and it will continue to be used in a variety of industries. This process is extremely accurate, efficient, and productive and offers a variety of benefits, including increased accuracy, efficiency, and productivity. It can be used to create a wide range of parts and products, including engine parts, medical implants, and aircraft components.

3. CNC machining offers several benefits, including increased accuracy, efficiency, and productivity.

The processing offers several distinct advantages over traditional methods of manufacturing. By utilizing computer-controlled cutting tools, it can create highly precise and intricate parts with very little human intervention. This allows for greater accuracy, efficiency, and productivity in the manufacturing process.

The machining has the ability to produce highly precise parts and components with very little waste. This ensures that each part is produced correctly and minimizes the amount of time, energy, and money that would otherwise be wasted if done manually. Additionally, CNC machining allows for greater accuracy and repeatability, resulting in highly consistent parts and components.

This processing also offers increased efficiency and productivity. With CNC machines, multiple parts can be created simultaneously, reducing the amount of time it takes to create a given product. This results in greater efficiency and enables manufacturers to produce a larger number of parts in a shorter amount of time, resulting in higher productivity.

CNC machining can be used to create a variety of parts and products, including engine parts, medical implants, and aircraft components. By utilizing the latest advances in technology, CNC machines can be used to produce complex shapes and intricate designs with very fine detail. This allows manufacturers to produce parts that are more durable and resistant to wear and tear.

This machining is an essential part of modern manufacturing and will continue to be used in a variety of industries. From aerospace to automotive, It offers a wide range of benefits over traditional manufacturing methods.

This includes increased accuracy, efficiency, and productivity, as well as the ability to produce highly precise and intricate parts with very little waste. As technology continues to advance, CNC machining is sure to remain an integral part of the manufacturing process.

4. CNC machining can be used to create a variety of parts and products, including engine parts, medical implants, and aircraft components.

The machining is a computer-controlled manufacturing process that can create highly precise and intricate parts. It is used in a variety of industries, including aerospace, automotive, and medical. It offers several benefits such as increased accuracy, efficiency, and productivity.

The processing is a great tool for creating a variety of parts and products for an array of industries. In the automotive industry, for example, It can be used to create engine parts such as valves, intake manifolds, and pistons.

CNC machining can also be used to create medical implants, such as artificial hips, orthopedic implants, and dental implants. In the aerospace industry, It can be used to create aircraft components, such as turbine blades and landing gear.

This processing is an essential part of modern manufacturing and its applications will continue to expand in the future. As technology advances, CNC machining will become more sophisticated, allowing for greater accuracy and more intricate parts.

The processing is also becoming more cost-effective, allowing companies to create more intricate parts at a lower cost. It offers a number of benefits that make it an ideal manufacturing process. It provides increased accuracy and precision, which is essential in the aerospace and medical industries. It is also more efficient and productive than traditional machining, allowing companies to produce more parts in less time.

Additionally, it is safer and more cost-effective than traditional machining, allowing companies to save money on materials and labor. The processing has become an essential part of modern manufacturing and its applications will continue to evolve as technology advances.

It is used in a variety of industries to create parts and products that would be difficult or impossible to create using traditional methods. CNC machining offers increased accuracy, efficiency, and productivity, as well as cost-savings.

5. CNC machining is an essential part of modern manufacturing and will continue to be used in a variety of industries.

This processing is an essential part of modern manufacturing and is used in a variety of industries for the creation of highly precise and intricate parts. It offers several benefits, including increased accuracy, efficiency, and productivity. CNC machining is used in a variety of industries, including aerospace, automotive, and medical.

The processing is used to create a variety of parts and products, including engine parts, medical implants, and aircraft components. It provides greater accuracy, precision, and repeatability than manual machining and can reduce costs associated with production. CNC machining also increases production rates, reduces waste, and improves product quality.

The benefits of this processing extend beyond just production. It can be used to create parts with complex shapes that would be impossible to create with manual or traditional machining. It can also be used to create parts with tighter tolerances and more precise features. CNC machining can also reduce the cost of labor associated with production, as it requires fewer people to operate.

It is an essential part of modern manufacturing and will continue to be used in a variety of industries. It provides a range of benefits, such as increased accuracy, efficiency, and productivity, as well as the ability to create more complex parts with tighter tolerances.

The processing is also cost effective, reduces labor costs, and increases production rates. CNC machining will continue to be used in a variety of industries for the foreseeable future.

I opted to undertake research on the manufacturing industry because my uncle is in it and I don’t know much about it. It’s fortunate that I stumbled on your site because you said how CNC machining, which is utilized in many different industries to produce extremely exact and intricate parts, is a crucial component of modern manufacturing. I appreciate you sharing! It undoubtedly gave me some understanding. I’ll be sure to let my uncle know about this.