CNC Turning milling compound machining

I. What is Turn-Milling CNC Machining?

CNC machining, short for Computer Numerical Control machining, is a manufacturing process that utilizes computerized controls to manipulate cutting tools and equipment for precision machining. Within the realm of CNC machining, there exists a specialized technique known as “turn-milling,” which combines two fundamental machining operations: turning and milling.

A. Distinction between Turning and Milling

Turning: Turning (also called lathing) is a machining process where a workpiece rotates while a cutting tool remains stationary. The tool cuts away material from the workpiece’s surface to create cylindrical shapes, such as shafts, pins, and various rotational components.

Milling: Milling, on the other hand, involves the use of rotating cutting tools to remove material from a stationary workpiece. It is employed to create a wide range of shapes, including slots, pockets, and complex 3D geometries.

B. Turn-milling compound machining

Turn-milling compound machining is a specialized CNC (Computer Numerical Control) machining technique that combines two essential processes, turning and milling, into a single machining operation. In this method, a workpiece undergoes both turning and milling simultaneously, resulting in several advantages:

Efficiency: Instead of separate setups for turning and milling, turn-milling performs both processes in one go. This reduces production time and labor, making the manufacturing process more efficient.

Precision: Turn-milling achieves high levels of precision and accuracy, making it ideal for creating intricate parts with tight tolerances. The simultaneous turning and milling action ensures that the workpiece is precisely shaped as needed.

Surface Finish: This technique can produce excellent surface finishes on the workpiece, often eliminating the need for additional finishing operations and saving time and resources.

Cost Savings: By combining operations and reducing setup times, turn-milling can lead to cost savings for manufacturers, making it a cost-effective choice for certain applications.

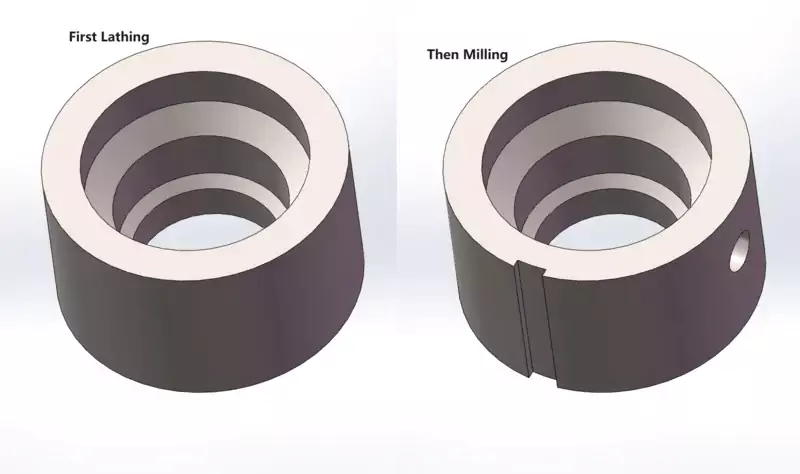

C. An Example

To achieve the final part as shown in the picture, a traditional approach requires two separate steps. First, we need to create a cylindrical blank, similar to the one on the left. Next, we utilize a CNC milling machine to meticulously mill the hole and groove, resulting in the final part resembling the one on the right. This process demands precise setup of the milling machine and accurate positioning of the blank to ensure that the hole and groove remain centered.

However, when employing a turn-milling compound machine, both turning and milling operations seamlessly combine into one. This eliminates the need for an additional milling setup and negates the necessity of repositioning the parts. There’s no risk of misalignment causing the groove or hole to deviate from the center. This approach not only saves time and money but also reduces the likelihood of errors, enhancing overall geometry accuracy.

The limitation of lathe-milling machining

Lathe-milling compound machines are essentially lathes with added milling capabilities, primarily built upon CNC lathe technology. In these machines, most of the power is directed toward the lathe spindle, leaving only a fraction for milling tool rotation. This means they can handle smaller milling tools.

However, these machines come with certain limitations. Due to their compact size, the milling head on lathe-milling compound machines lacks rigidity. They were originally designed to tackle parts that require a bit of milling during the turning process.

When it comes to parts demanding substantial milling or the use of larger milling tools, these machines might not be the best choice. They can lead to longer processing times due to the need for smaller tools and reduced rigidity. This can even result in tool vibrations. In such cases, it’s often more efficient to rough out the part on a standard CNC turning lathe and then finish the milling on a separate CNC milling machine.

Another limitation of CNC turning milling machines is the quantity of milling tools they can use at the same time. While CNC milling machines often have tool stock with the capacity for 18 to 64 different tools, CNC turning milling compounds have more limited space, typically accommodating only 4 to 12 milling tools. Consequently, their ability to perform milling operations in one operation is restricted.

In a nutshell, lathe-milling compound machines are best suited for cylindrical parts with modest milling requirements. There are high-performance variations, but they come at a premium, making the combination of a CNC lathe and a standalone CNC milling center a more cost-effective solution for many industries.

Axes of a CNC lathe-milling machine tool

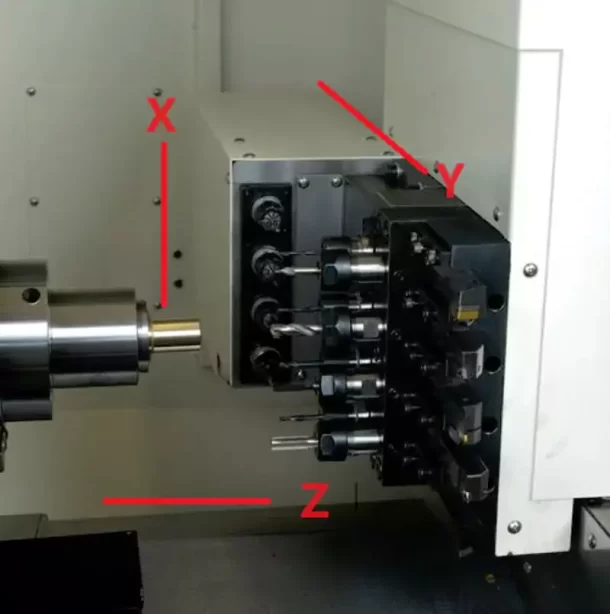

Regular CNC lathes have two main tool movement directions: along the spindle’s axis (z-direction) and perpendicular to it (y-direction). Even basic CNC lathe-milling compounds can only move their tools in these two ways, allowing them to mill and drill along the part’s centerline.

In more advanced versions, these machines add another movement option by allowing the tools to also move along the x-axis. This means they can handle most milling tasks that a typical 4-axis CNC milling center can.

The most advanced CNC turning milling compounds take it a step further, allowing their tools to rotate at any angle relative to the z-axis. These machines can tackle some of the complex CNC milling jobs typically reserved for 5-axis CNC machining centers.

Advantages and Disadvantages of CNC Turn-Milling Machining

CNC turn-milling machining comes with its own set of advantages and disadvantages, which we’ll discuss in clear and simple terms:

Advantages:

Production Efficiency: Combining CNC turning and milling processes streamlines production, reducing setup time, manufacturing cycle time, and, in many cases, overall CNC machining time.

processing Accuracy: Simultaneous CNC turning and milling deliver high precision and accuracy, making them suitable for parts with tight tolerances and intricate features.

Cost Savings: By minimizing the need for separate setups and reducing labor, CNC turn-milling can lead to significant cost savings over time.

Disadvantages:

A. Increased Complexity: The integration of two CNC machining processes into one can introduce complexity, both in terms of programming and CNC machine operation.

B. Specialized Skill Requirements: Operating and programming CNC turn-milling machines may require specialized skills, potentially limiting the pool of available operators.

C. Equipment and Tooling Costs: CNC Turn-milling machines can be a significant investment, and tooling and equipment maintenance costs can also be relatively high.

Conclusion

CNC turn-milling machining is a versatile and powerful solution for manufacturing a wide range of parts. It offers efficiency, precision, and cost savings, making it a valuable tool for many industries. However, it’s important to recognize its limitations, such as increased complexity, specialized skill requirements, and equipment costs.

At Capable Machining, we understand the intricacies of CNC machining, including the benefits and challenges of turn-milling. Our team of skilled professionals is equipped with the expertise and experience needed to deliver high-quality machining solutions tailored to your specific requirements. Whether you need precision parts with tight tolerances or complex components, we have the knowledge and capabilities to meet your needs. To learn more about our services and how we can assist with your machining projects, visit capablemachining.com. We’re here to help you achieve your manufacturing goals efficiently and cost-effectively.

2 Comments

Leave a Comment

You must be logged in to post a comment.

I couldn’t resist commenting. Well written!

Thank you for your dedication!