Complex whole impeller CNC machining key technology

Currently, more fields are beginning to widely use the whole impeller equipment, and the complex mechanical equipment used in the whole impeller equipment has a more complex structure, so the CNC machining accuracy puts forward higher requirements.

To meet the processing requirements, the relevant technical personnel need to strengthen the analysis of CNC machining key technologies and optimize the design and processing parts. Therefore, it is necessary to increase efforts to study the key technology of CNC machining of complex whole impellers to carry out production work smoothly.

Impeller overview

At present, a variety of products include impellers, such as hydraulic turbines steam turbines, and aviation engines and other products, impellers are important parts.

Impellers pressurize gases and liquids to achieve the purpose of energy conversion. The impeller consists of a disk and paddles.

According to its composition, the impeller can be divided into open, semi-closed, and closed three types. According to the different speeds, there are high-speed impellers, medium-speed impellers, and low-speed impellers.

Impeller is related to the use of mechanical equipment, its quality is also directly related to the efficiency and service life of the machine.

Impeller manufacturing difficulty is mainly reflected in the manufacture of the blade, especially for aerospace and other industries of the impeller, because it has a large degree of torsion and narrow flow channel, its manufacturing precision puts forward higher requirements, and each piece of the blade ensures consistency, and the roughness of its surface should also reach a certain standard.

In addition, due to the role of material factors, the entire blade of CNC manufacturing has become very difficult.

Complex whole impeller CNC machining characteristics and processes

1. Processing characteristics

In the complex overall impeller CNC machining process, the a need to comprehensively utilize digital information control technology and CNC machining methods, which is conducive to automation and efficient processing of the impeller structure.

After the impeller processing, because the thickness of the blade is small, the tool is easy to deform in the process of processing, for the overall processing quality impact.

It is difficult to accurately calculate the tool axis vector because of the large twisting degree of the blade. Because the distance between the impeller blades is relatively close, coupled with a large leaf height, thus increases the difficulty of CNC machining.

To avoid the above problems, in the processing of the whole impeller, the need to formulate a processing program in advance, and need to draw a detailed parts processing diagram.

Based on the development of impeller processing flow, reasonable division of specific work content, so that the processing apparatus and processing tools can be efficiently articulated, and can accurately locate the impeller parts.

In addition, we need to strictly control the impeller CNC machining errors, and the machine tool technology to play a guiding role.

2. Machining process

Complex whole impeller CNC machining and general impeller machining work has a similar processing process, first of all need to draw machining drawings, according to drawings to analyze the structure and shape of parts and materials, etc., for subsequent processing work to provide convenience.

Secondly, it is necessary to design the machining process in combination with the principle of CNC machining. In practice, a reasonable selection of machine tools and equipment is needed, and the need to accurately locate the processing parts and clamping position.

Subsequently, the rational arrangement of processing steps, to determine the correct way to use the equipment. Pay attention to filling in the details of the processing documents, and need to strictly check the processing program.

After completing the operational summary, you can carry out CNC machining according to the design, because there are still deficiencies in the process, so the programmer needs to come to the processing site to guide the actual processing and to facilitate the operator to understand the specific work procedures.

3. Technology development

Based on the CNC process of the whole blade, intelligent control methods have been adopted to realize the CNC machining of the blade.

In the complex whole impeller CNC machining process, involving more processing objects, it is difficult to batch production of products.

Due to the small number of similar products, precision machining on CNC machine tools requires a relatively high degree of accuracy. Digital and intelligent CNC machining of large and complex blades was carried out.

The main work is to select machinable parts, determine the machining program, draw the impeller drawings, and decide the machining process. In addition, the work of modifying the blade is also included. From APT programming to the CATIA program, and now the CNC manufacturing process for large and complex blades.

On this basis, many international researchers have carried out a series of studies and achieved good results.

For example, in the five-axis linkage CNC system, analyzed the five-axis linkage CNC machine tools, the causes of nonlinear error, and the establishment of a five-axis linkage CNC machine tools suitable for nonlinear error solving method.

To solve the problems of nonlinear deviation caused by the rotation of the tool axis vector and the restriction of the rotary stroke of the machine tool, the tool position detection method suitable for 5-axis CNC is studied.

Overall impeller design and manufacturing system planning

In the design and production of the whole impeller, to make it adapt to different environments, it is necessary to make it have a large bending radius.

In the traditional impeller production process, the first use of machine tools to cast the shape of the impeller, and then use the machine to process it, you can also use a separate processing method, and then finally weld all the blades, and further unified grinding, polishing processing work.

At present, due to the use of modern CNC machines for milling, compared with the conventional process, the process has the advantages of high precision, short production cycle, ease of adjustment, and so on. In the manufacture of CNC machines, the whole blade must be forged into a blank before it is machined.

Therefore, MASTERCAM software is used to program the whole blade systematically to make it have high precision.

The first step is modeling through CAD, followed by the establishment of tool trajectories, and finally the simulation of the cutting process.

Impeller CAD modeling process

Through reverse engineering analysis to obtain the overall impeller blade data, engineers can also obtain the relevant data through detailed calculations.

In the process of using reverse engineering, combined with the impeller external measurements in the impeller working state data, and then through the software editing to obtain the ideal blade data, and then enter the data in the CAD system, the CAD editing process, so that to obtain the CAD model of the impeller.

According to the specific use of the impeller to change the overall impeller structure and a blade shape, the current main forms utilized include the straight curved surface type and free-form surface type.

In the construction of the impeller model, first of all, the establishment of the impeller rotary body, followed by the determination of the impeller interface characteristics curve, followed by the use of computer simulation of the overall impeller model manufacturing, usually the use of UG software mixed scanning impeller surface.

Complex whole impeller CNC machining key technology

1. Planning technology

In the process of CNC machining, planning technology plays an important role, mainly based on the tool track to use planning technology.

The original tool track planning, usually combined with parts surface data and geometric form, but this method is not conducive to the efficient use of parts and components, at the same time it is difficult to meet the blade configuration standards, for the root part of the leaf will also have a restrictive effect, in the actual processing, parts, and tools are prone to mistakenly touch the problem of lowering the quality of the impeller processing.

For the new impeller processing work, in the planning process, the choice of parameter mapping technology is conducive to reducing the tool and blade accidentally touching the problem, and re-planning the tool trajectory, to avoid the tool trajectory to appear the problem of empty stroke.

In addition, the blade flow line and tool trajectory can be fixed, which is conducive to efficient processing of impeller components, while ensuring the overall processing quality.

2. Processing technology

Processing complex impeller process, mainly on the entire blade of the leading and trailing edge chamfering processing. Because in the CNC processing of complex whole impellers, many processes have to rely on advanced technology to achieve the purpose of high-efficiency processing.

However, the current complex blade CNC machining technology is still in the stage of continuous upgrading and innovation, it is difficult to adapt to the complex blade precision machining needs. In the processing of blade leading and trailing edge chamfering, the chord intercept method is used to solve the cutting path, which is conducive to the improvement of the machining level.

This algorithm is characterized by simple arithmetic and a small possibility of calculation and manufacturing errors.

When calculating the step size, the nature of the surface needs to be analyzed comprehensively. If the surface is characterized by flatness, the step size will be increased, and the curvature of the surface will be reduced at the same time. Gradually increasing surface curvature will reduce the step size.

It is usually necessary to reduce the radius of the exhaust edge and the inlet edge of the blade to optimize the overall impeller performance. If the radius of the fillet at the tip of the blade is around 0.15mm, the blade axis vector will be rotated rapidly, thus increasing the error and causing the overcutting problem at the edge.

Therefore, it is necessary to strengthen the control of the rounded part of the machining work, to avoid the problem of error, combined with the actual situation of the error to supplement and improve the reasonableness of the step length of the tool.

3. Roughing and fine machining toolpath design

Roughing toolpath design

Roughing toolpath trajectory is designed to remove excess material in time to efficiently complete the processing work.

Therefore, the selection of tools needs to reason that the large radius ball end milling cutter, in the roughing process, the offset method, and layer cutting method of the use of a higher rate, in the fine blank machining process of the offset method of the use of a higher frequency, you can implement the casting and forging of the blank.

If the blank has a large margin, it is suitable to utilize the layer-cutting method.

To efficiently complete the machining work, you need to reasonably set the safety plane and starting point and layer high.

Finishing toolpath design

In the finishing process, it is necessary to optimize the design of the tool path trajectory to ensure the rationality of the tool route method, which is conducive to improving the machining accuracy and avoiding machining errors.

Especially need to scientifically design the runner trajectory and blade trajectory. To protect the processing quality and efficiency need to reasonably select the tool inclination and diameter, currently in the process of machining, such as the residual height spiral trajectory generation method has a higher application rate.

4. Modification technology

Complex whole impeller CNC machining involves more parts, and different parts have complex structures, such as the blade form is very complex, and there are more influencing factors in the processing stage.

For example, for the encircling blade, in the design of the tool trajectory found between the tool and blade is easy to accidentally touch the problem. The implementation of tool axis vector transformation technology can optimize the control role, and the operation of the technology is less difficult, mainly in the tool axis trajectory design process using the linear interpolation calculation method.

In the machining process, mainly in the tool drop point for interpolation, reduces the incidence of the problem of false contact, and is conducive to high-quality processing of the whole impeller.

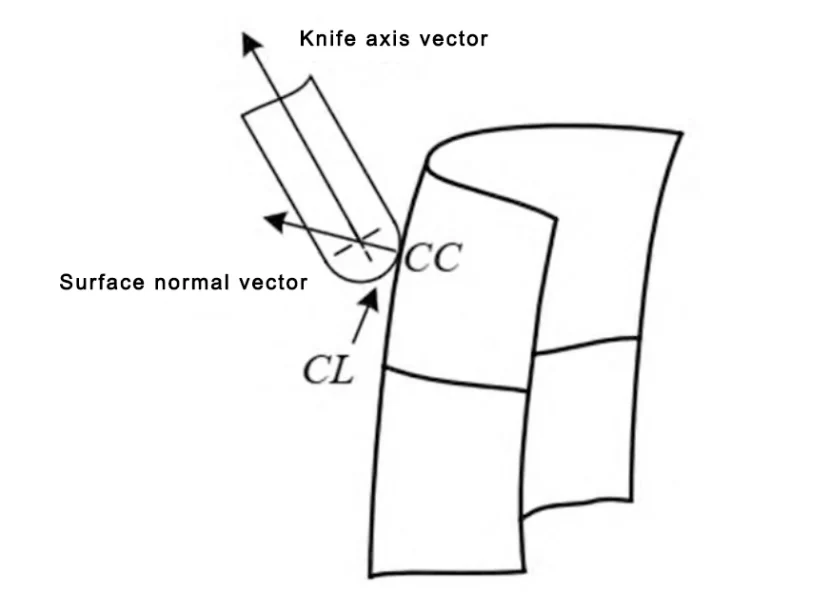

The determination of the tool axis vector is a key issue in the design of five-coordinate CNC programming.

Five-coordinate method for impeller processing and manufacturing has brought convenience but also increased the difficulty of CNC programming.

The core is the tool axis vector and smooth processing. Due to the complex shape of the whole impeller, all kinds of interference and conflict are often encountered in CNC machining. With the change in complexity and structure pattern, the control of the tool axis vector also has some difficulties. For open impellers, it is not necessary to rotate the tool axis vector too much to facilitate the movement of the tool.

For straight curved blades, side milling is necessary. For free-form blades, the machining is cumbersome. For the whole impeller with crown, the machining is done in pieces, and multiple clamping is possible.

However, because of the presence of the crown, interference between gears is easy to occur. Because of the large deformation of the whole impeller and the small clearance between the blades, it is very easy to produce global interference of the tool axis when using the circular tool travel method.

Tool axis vector smoothing refers to the smooth and uniform change of the tool axis vector during cutting. A smooth transition improves the finish and surface quality of the workpiece and reduces vibration during cutting.

If the axial direction of the tool is inconsistent, the speed or velocity will be slow and slow, so that the tool axis swings, resulting in biting, and serious parts can be scrapped.

Fig. 1 Schematic diagram of tool axis vector

5. Blade distortion control technology

To avoid the problem of blade distortion, the selection of tangential parameters at each step should be taken into consideration when carrying out the CNC manufacturing of complex integral blades.

Therefore, when establishing the target equation, it is necessary to reasonably optimize the target to achieve the minimum blade deformation. On this basis, a suitable cutting process can be selected reasonably. Currently, to minimize the deformation of the blade as the premise of the optimization objective, there are two different algorithms: one is the direct simulation method, and the other is to use the finite element method for modeling.

Regardless of the method, the cutting force formula is established based on the cutting amount, and the calculated cutting force is applied to the modeling of the workpiece. By analyzing the transient process of the workpiece, effective control of the cutting force of the workpiece can be realized.

However, due to the direct modeling method, there are many limitations in the modeling process, so it is not suitable for complex parts. By using the finite element modeling method, the blade is first modeled by a finite element and then analyzed by force.

Based on this, the finite element software can be used to calculate and solve the deformation of the blade, and control measures can be taken in time.

6. Detection and Data Analysis Technology

Analysis of the effect of parts processing needs to use testing technology, and staff combined with the results of the implementation of targeted improvement measures to protect the overall quality of processing. Timely remedial treatment of parts that do not meet the specifications.

The modern manufacturing industry requires strict processing accuracy while paying great attention to the performance of parts and modeling and other aspects, so the a need for a reasonable choice of testing technology.

In the inspection of blade parts, the use of CMM inspection method, can be utilized on a variety of occasions, to obtain accurate measurement results, but this method focuses on environmental changes, in the field measurement is not suitable for use.

The profile sample inspection method has a higher utilization rate. It can be utilized in on-site inspection as it can realize high-volume inspection work and improve overall work efficiency. However, this method has shortcomings in terms of detection accuracy.

In recent years, the gradual use of optical measurement methods, not only suitable for on-site measurement process, at the same time can be comprehensive coverage of the surface of the parts, is conducive to the efficient completion of the measurement work, but the need to invest more money, and there are some shortcomings in the measurement accuracy.

The whole impeller coordinate-free CNC machining process planning

1. Reasonable selection of the overall impeller blanks

Selection of the blank can not exist cutting allowance. Processing of the initial blank, you can comprehensively utilize the turning and forging methods. When processing free-form parts, ensure the uniformity of the finishing allowance. The shape and size of the blank should be designed accurately according to the shape and size of the part.

2. Division of CNC machining stages

In the machining process, it is necessary to remove about 70% of the material, and surface machining of more content, including, for example, leaf root fillet and blade and other parts of the machining work.

Because the overall impeller parts are very complex, can be further divided into CNC machining for roughing and semi-finishing and finishing three parts.

3. Selection of process datum

In the machining stage, it is usually necessary to coincide with the Z-axis and C-axis of the programmed coordinate system, and at the same time, it is also necessary to coincide with the C-axis and the rotational axis of the part. Usually, the Z-axis is used as the axis, if not it is used as the axis. To reduce the difficulty of programming, the axes need to be adjusted so that they coincide with the Z-axis.

Conclusion

In practice, continuous innovation of complex whole impeller CNC machining key technologies can make up for the shortcomings of traditional machining production work, to solve the complex whole impeller machining process problems.

However, the continuous innovation of technology, also increases the difficulty of technical operation, for the staff to put forward higher requirements, the processing staff skilled use of key technologies, especially need to pay attention to the deformation control and smoothing, etc., by mastering the technical points, to ensure that the process benchmarks for the reasonableness of the actual processing stage at the same time for a reasonable division, to accurately complete the processing work.

In the future development process, the relevant technical personnel need to continuously improve the research efforts, and continue to learn advanced technology, to ensure the overall control effect, and optimize the performance of the impeller.