Designing Ribs For Injection Molded Plastic Components: A Comprehensive Guide

Ribs in injection-molded parts add strength and stiffness, making the part more rigid. Without ribs, we’d need a thicker, heavier part to achieve the same stiffness. To avoid excessive sinking and weight, the ribs’ thickness should be about 50% of the nominal wall thickness. Additionally, it’s a good idea to connect the ribs to the base with round corners. This article will discuss the best practices for rib designs of injection-molded parts.

The role of ribs in injection-molded parts

Ribs are an integral part of the functionality of injection-molded plastic parts.

Strengthen product durability and rigidity without thickening the molded part’s main walls. Minimize plastic waste in the plastic injection molding process. Avoid adding unnecessary weight to the product. Optimize cost efficiency.

Ribs can prevent product warpage and deformation resulting from uneven forces due to varying wall thicknesses.

Ribs can create additional pathways for molten plastic flow to fill the thin sections of injection-molded parts.

The right dimensions to avoid sink marks

One of the most important principles in the design of plastic injection-molded parts is to maintain a uniform wall thickness. When the wall thickness changes, plastic injection-molded parts will produce sink marks. The ribs will inevitably cause changes in the wall thickness of the injection-molded parts to a certain extent. Therefore, when deciding what size the rib sections should be, the primary consideration is how to avoid sink marks.

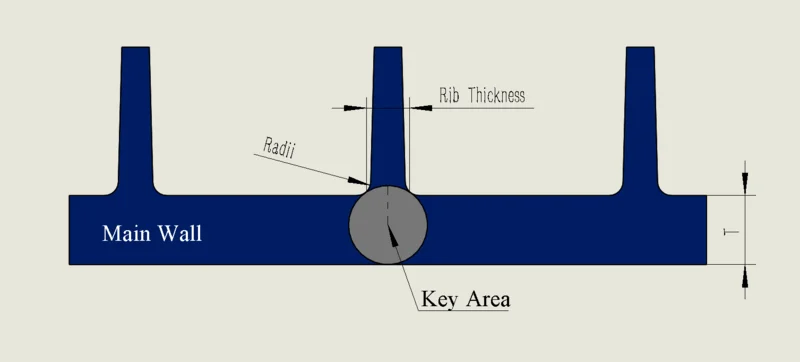

As shown in the figure, when adding ribs, the diameter of the key area should be reduced as much as possible. The size of the key area represents the wall thickness change caused by the ribs. Obviously, the corner radius and the rib thickness are the most crucial numbers to minimize the key area.

Rib Thickness

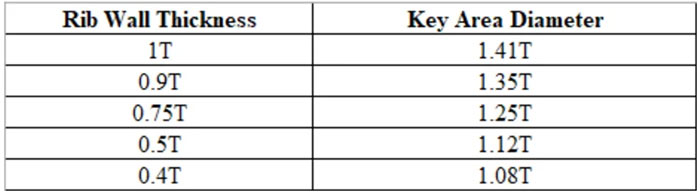

The table lists the effect of rib thickness on key area diameter. When the rib thickness is below 50% of the nominal wall thickness the key area diameter only increases less than 12% of the nominal wall thickness. A general rule of rib design is to keep the rib thickness around 50% of the nominal wall thickness. Depending on the plastic material property used, the rib thickness is suggested to be 40% ~ 75% nominal wall thickness.

Rib Radii

It is suggested to include a radius where the rib meets the base or sidewall. This reduces stress concentration, boosts rib strength, and makes smoother plastic material flow when plastic injection molding. Molds with larger radii are also slightly cheaper to make. Yet, larger radii expand the diameter of the key area, increasing the likelihood of sink marks. It is suggested to keep the radii between 25% to 50% of the nominal wall thickness.

Rib Height vs Number

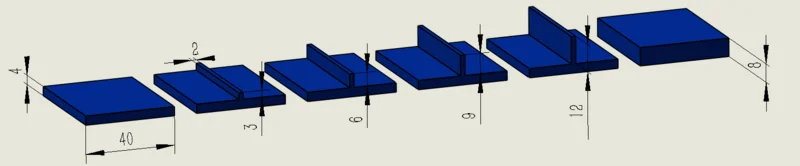

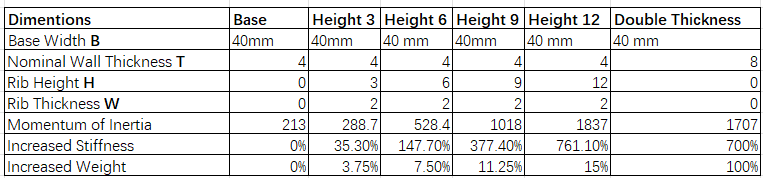

The following table is a case study results on the effect of rib height on the stiffness of parts. The momentum of inertia in the table indicates how difficult it is to bend a plastic part in a certain direction. As shown in the table, we can draw two conclusions, 1. The height of the ribs can increase the stiffness of the injection molded part in a geometric progression. 2. The ribs increase the stiffness of the molded part without adding much weight to it. For example, in the table, when the rib height is increased to 12mm, the stiffness increases by 7.6 times, while the weight only increases by 15%. For comparison, when the overall wall thickness of the material is doubled, the weight of the material is doubled, but the stiffness is only increased by 7 times.

However, high rib height causes problems too. When the rib height is excessively high, it can cause infilling issues during the plastic injection molding process. This occurs because the molten plastic struggles to fully fill the tall and narrow spaces of the rib cavity, leading to incomplete or inadequate filling. The plastic may not reach the tip of the ribs, resulting in unfilled or partially filled sections, which can weaken the rib’s structural integrity and create defects in the final molded part.

The recommended maximum rib height is three times the nominal wall thickness. If additional stiffness is required, it’s preferable to utilize multiple shorter ribs.

Draft Angle

In order for the part to be ejected smoothly in the injection molding process, the draft angle is necessary. The draft angle of ribs is generally controlled at 0.5~2°, and 1~1.5° are most common. The size of the draft angle is mainly considered from two aspects.

1. The property of the material, especially the shrinkage and viscosity of the material. Materials with high viscosity and large shrinkage are more likely to adhere to the mold core, so a larger draft angle is required. Materials with low viscosity and low shrinkage can use smaller draft angles.

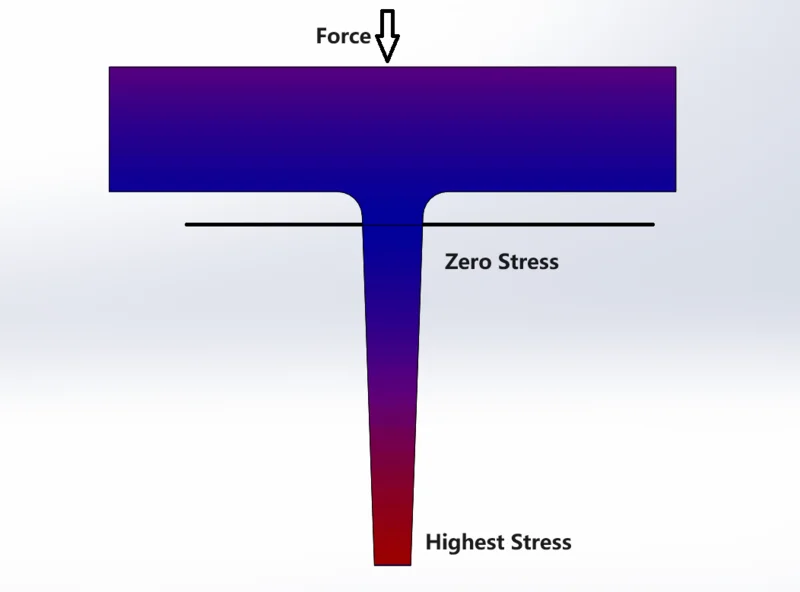

2. Avoid making the top width of the rib too small. This requires comprehensive consideration of rib thickness, height, and draft angle. If the top width of the rib is too small, it will be difficult to eject the part during the plastic injection molding as there may not be enough area left for the ejection pins. As shown in the figure below, the bending stress of the part is mainly concentrated at the top of the rib. From mechanical considerations, the top of the rib should not be too narrow either. For the same reason, the rib height should also be controlled within a certain range.

The properties of material

From the production point of view, the material’s physical properties, such as melt viscosity and shrinkage, strongly influence the rib design. For high-shrinkage material, relatively low rib thickness (for example 40% nominal wall thickness or less), and smaller radii should be utilized. For low-shrinkage material, for better stiffness, rib thickness can be as much as 75% nominal wall thickness. A high melt viscosity material needs lower rib heights or bigger rib thickness to make sure the injection molded part is fully filled when injection molding.

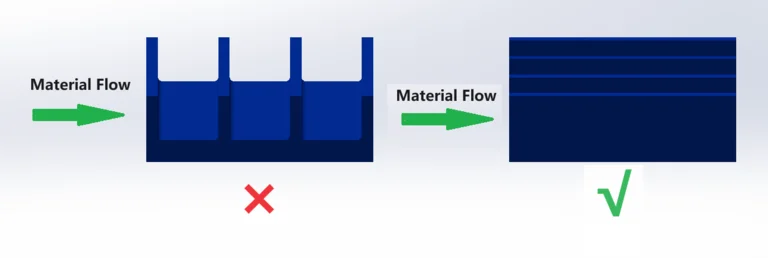

The direction of the ribs

From the design point of view, positioning ribs in the direction of bending force optimizes stiffness. From the production point of view, aligning ribs with the material flow direction reduces the likelihood of incomplete filling and air entrapment. If stiffness is required on both sides, ribs should be employed on each side.

Rib Spacing

As mentioned earlier, multiple shorter ribs are preferred to one single tall rib. If multiple ribs are utilized, excessive crowding is undesirable. Ribs should maintain a minimum spacing equal to their height, which should not exceed 3 times the primary wall thickness. Having ribs closer than this poses a risk of inadequate cooling of the rib base, potentially prolonging the injection molding process and increasing both cycle time and part cost. Additionally, if rib spacing is too narrow, it also means the mold core between ribs is possibly too thin and easy to damage during the manufacturing process.

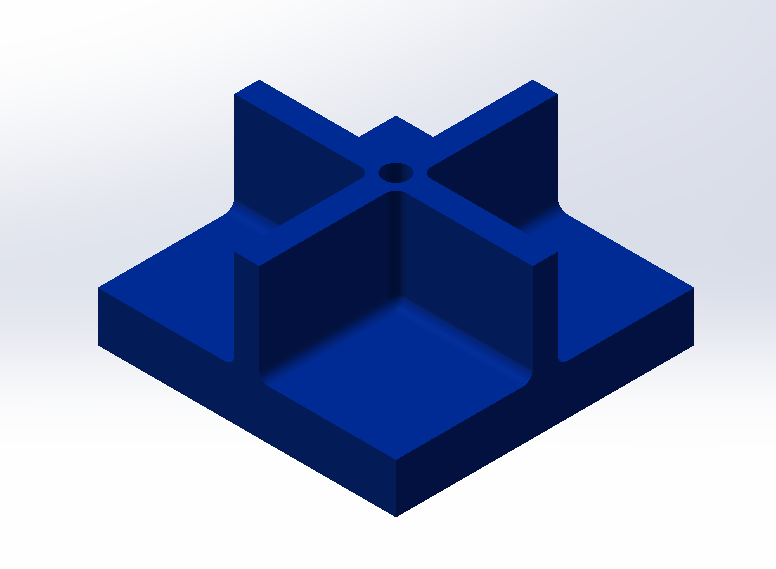

Rib Coring Out

If thick ribs are necessary, core out in the back or below them. This makes the rib walls thinner and can stop cosmetic sinking. The coring out is often used in rib intersections. The size of the core should also follow the rule of maintaining uniform wall thickness.

Rules are made to be broken

In summary, the general guide to rib design of plastic injection molded parts is as follows:

Rib thickness 40%~75% of nominal wall thickness.

Rib radii 25%~50% of nominal wall thickness.

Rib height maximum height less than 3 times the nominal wall thickness.

Multiple ribs are preferred to a single tall rib.

Material property plays an important role in deciding the dimensions of ribs.

Rib spacing should be no less than 3 times the nominal wall thickness.

The rib direction should be along the bending force or/and material flow direction in injection molding.

However, these are just general guidelines. In real-life design, many successful cases do not fully adopt these guidelines. Even if these guidelines are fully followed, there are still many difficult problems in plastic injection molding. For example, ribs thinner than the nominal wall thickness cause the ribs to cool first and the main wall to cool later, thus causing the part to warp. In actual design, we often encounter conflicts among these guidelines, making it difficult to choose. These guidelines are sometimes not always applicable. For example, some structural parts do not need to consider cosmetic effects, so even if sink marks occur, it is not a big problem. In this case, the thickness of the ribs can be considered to be the same as the main wall. Sometimes sink marks are completely unacceptable, in which case it is necessary to consider using an even smaller rib thickness and only use 0 radii on the rib base.

All in all, the design guidelines for ribs of plastic injection molded parts described in this article are only guidelines, and they need to be used flexibly and adapted in practice.

As you delve into plastic part design, having the right support matters. Explore CapableMachining.com for valuable insights and collaboration. Leveraging their expertise can elevate your designs, ensuring efficiency and success. With CapableMachining.com as your partner, bringing your plastic injection part designs to life becomes a smoother journey.